Hamamatsu Photonics has developed an X-ray TDI camera with enhanced sensitivity to low energy X-rays for in-line non-destructive inspection of thin objects and light-element materials

*1 TDI:Abbreviation for Time Delay Integration. TDI is a specialized signal readout mode capable of imaging moving objects with high speed and high sensitivity.

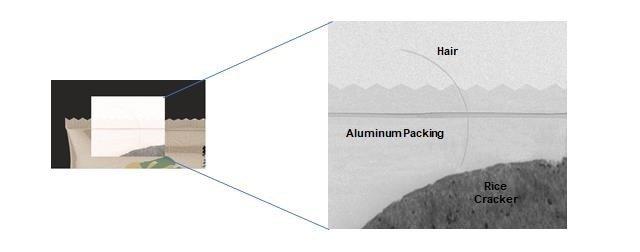

The X-ray TDI camera captures X-ray images with high contrast according to the difference in the amount of X-ray transmission. Areas with high X-ray transmission are bright and areas with low X-ray transmission are dark.

X-ray Non-destructive Inspection

X-rays have the property of being able to pass through materials. X-ray non-destructive inspection takes advantage of this feature to view and examine the internal state of an object without damaging it. Thick materials and substances with a high atomic number tend to block X-rays. If they are present in an object inspected with X-rays, the captured X-ray image will have a contrast according to differences in their thickness and materials, allowing accurate detection of contaminants that may get into foodstuffs or industrial products.

Product Overview

This X-ray TDI camera has high sensitivity to low-energy X-rays and so captures high-contrast X-ray images of thin objects and light-element materials.

Hamamatsu Photonics has manufactured and sold high-performance cameras for non-destructive X-ray inspection for applications including in-line inspection of foodstuffs. In the food industry, due to increasing concerns about food safety, non-destructive X-ray inspection is becoming more and more important, for example, for detecting contaminants to prevent intrusion of stones or metals and in finding poor package sealing (*2) to prevent deterioration of product quality. In recent years, processed foods and food products are supplied in various packages that utilize thin sheets and light-element materials as packing materials. X-rays easily transmit through these types of packing materials causing the problem of low contrast X-ray images. This has focused a great deal of attention on X-ray cameras with high sensitivity to low energy X-rays that can make highly accurate inspection by capturing high-contrast X-ray images of even thin objects and light-element materials.

By utilizing a new technique to detect low-energy X-rays with high sensitivity and making the design from scratch, we succeeded in developing an X-ray TDI camera that has enhanced sensitivity to low energy X-rays. High-contrast images can now be captured from low-energy X-rays that do not easily pass through thin objects and light-element materials, leading to improved inspection accuracy in detecting tiny contaminants such as hair in thin aluminum food packing, irregular thickness of aluminum sheets, or uneven adhesive coating on transportation equipment parts using CFRP. Moreover, employing a high-performance photodetector we developed in-house, has boosted the signal readout speed to 1.8 times the ordinary speed to allow streamlined in-line 100% inspection of products. Another feature is that this X-ray TDI camera also captures high-energy X-ray images and so can simultaneously inspect for contaminants in objects containing multiple materials.

To meet market needs, we will continue to develop X-ray cameras that are more compact and have a larger imaging area.

*2: Poor package sealing is caused by internal contents or contaminants that are stuck or trapped in the package sealing for products such as foodstuffs. Poor package sealing can cause deterioration in product quality.

Main Product Features

1. High sensitivity to low-energy X-rays

Non-destructive X-ray inspection captures internal images of a target object by usually utilizing the combination of a scintillator that produces light when irradiated with X-rays and a sensor that detects light. Our new X-ray TDI camera was redesigned from scratch by applying a new technique to detect low-energy X-rays with high sensitivity, so that it efficiently detects light emitted by irradiation of low-level energy X-rays. The result is a high-contrast X-ray image captured at an energy of about 20 keV, which is lower than the energy level of 40 keV used for ordinary X-ray inspection.

2. Improved readout speed

Using a high performance photodetector we developed in-house, a signal readout speed of 153.8 meters per minute, which is 1.8 times faster than conventional methods, has been achieved. This allows streamlined in-line 100% inspection of products.

3. Detects X-rays over a broad energy range

This new X-ray TDI camera detects X-rays over a broad energy range from low to high energy levels. This means it can simultaneously inspect for contaminants in objects containing thick materials that tend to block X-rays, and thin materials that tend to easily pass X-rays.

For further information contact us on email: europe@hamamatsu.de or visit our website: www.hamamatsu.com

Hamamatsu Photonics Deutschland GmbH

Arzberger Str. 10

82211 Herrsching am Ammersee

Telefon: +49 (8152) 375-0

Telefax: +49 (8152) 375-199

http://www.hamamatsu.com

Public Relations

Telefon: +49 (8152) 375-185

Fax: +49 (8152) 375-199

E-Mail: rfritsch@hamamatsu.de

![]()