Based on customer feedback, Kipp Umwelttechnik improves the FilterMaster system when cleaning large, heavily inorganic filters

Findings from a customer-oriented problem solution led to a significant improvement in the cleaning performance of the FilterMaster system when cleaning heavily loaded large filters. The patented FilterMaster process can now also be used successfully with non-catalytically loaded CRT filters.

With the patented FilterMaster system and a subsequent, innovative, gentle after-treatment, Kipp Umwelttechnik solves cleaning problems with CRT filters that are heavily contaminated with inorganic ash and are installed behind a NOX catalyst. These usually do not have a catalytically active coating.

Several large filters of a customer, which always showed a rapid increase in contamination and were known to the customer as problematic, were cleaned with the FilterMaster standard method and showed a clear weight loss after cleaning, which was almost the same for all filters. The differential pressure values corresponded to a new filter. The filters have been cleaned and returned to the customer.

However, it was shown that the operating time of the cleaned filter was significantly reduced compared to the operating time of new filters. The customer then left a filter to Kipp Umwelttechnik to investigate the causes.

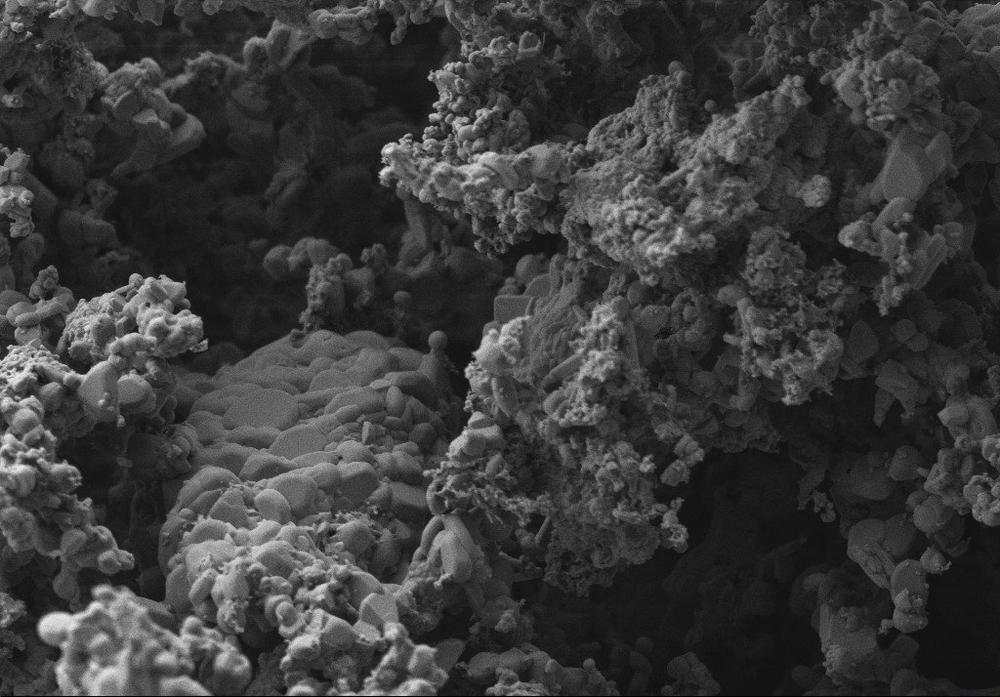

The filter housing was opened and samples of the CRT filter crystal were taken. It was shown that the channels of the CRT filter were largely permeable, but still had residues on the inner walls. The residues were examined with the analytical methods REM / EDX. These were the usual inorganic residues from the combustion of diesel fuel, engine oil and coolant. The latter two components were disproportionately represented. The unusually high amount of inorganic ash can be explained by the increased combustion of engine oil and coolant, since these have a much higher inorganic additive.

This investigation provided two important insights.

1. Opening a filter has shown that our previous test methods (differential pressure test, volume flow measurement) can only give a statement about the cleaning success of the upstream NOX cat in this case.

Reason: The total cross section of the passage openings of the NOX cat in relation to the total cross section of the passage openings of the CRT filter appears to be significantly smaller. NOX-Kat and CRT-Filters are very close to each other. Since the area with the smallest cross-section determines the volume flow, the NOX catalyst is decisive as long as the air passage of the filter crystal is higher than that of the catalyst. However, this is presumably also the case when the filter walls are still highly inorganic. The aforementioned tests therefore had no suitable information on the cleaning quality of the CRT filter. The weight measurement, which is also included in our test procedure, can only provide clues, since the loadings of the filters are not the same and the weight of new filters is subject to a large spread.

2. Our patented standard FilterMaster process gently removes soot and ash from catalytically coated CRT filters at relatively low drying temperatures. This results in a complete breakdown of soot. Inorganic ash is practically completely removed. In the case of uncoated CRT filters with an upstream NOX catalyst, the soot is converted, but the inorganic ash is only loosened in powder form in some cases. A very small proportion also remains firmly adhering to the filter walls through channels.

In this regard, ways for a successful after treatment after using our standard procedure had to be found that do not impair the performance of the NOX-Kat. The total costs for this were borne by Kipp Umwelttechnik.

With some effort we have found solutions to both problems. In the meantime, the customer has also been provided with several cleaned filters with the new findings. As a result, we were able to discharge substantial amounts of the residues listed in the analysis and also generate an inspection factor. In our view, the filters are now almost as good as new. If required / for other filter types, cleaning methods and test methods can now be readjusted at any time.

The entire process is now available on the market.

Images: Kipp Umwelttechnik GmbH

In the field of industrial cleaning, Kipp Umwelttechnik GmbH is the specialist for thorough and gentle cleaning in industry and for building cleaning.

Kipp Umwelttechnik GmbH was founded in 1991 as a sister company to the construction company Jens W. Kipp Tiefbau GmbH, which has existed since 1971. Both companies are businesses managed by entrepreneurs.

mycon GmbH has added to the group made up of Kipp Umwelttechnik GmbH and Jens W. Kipp Tiefbau GmbH since 2002.

About mycon GmbH, www.mycon.info

As a sister company to the service business Kipp Umwelttechnik GmbH, mycon GmbH is involved with the development, production and sale of new products and automation technologies.

mycon GmbH currently supplies to customers in approx. 40 countries.

Many years of experience from the field of industry service led to several systems developments and patents, some of which with international recognition. mycon GmbH takes care of customer groups from a variety of industry and service fields.

Kipp Umwelttechnik GmbH

Senner Straße 156

33659 Bielefeld

Telefon: +49 (521) 403171

Telefax: +49 (521) 402482

http://www.kipp-umwelttechnik.de/

Telefon: +49 (521) 403171

Fax: +49 (521) 402482

E-Mail: marketing@kipp-umwelttechnik.de

![]()