Standard Lithium Successfully Commissioned Demonstration Plant Despite COVID-19

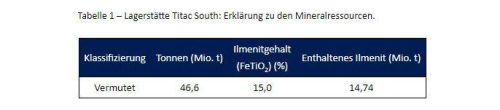

All presented tables are my own material, unless stated otherwise.

All pictures are company material, unless stated otherwise.

All currencies are in US Dollars, unless stated otherwise

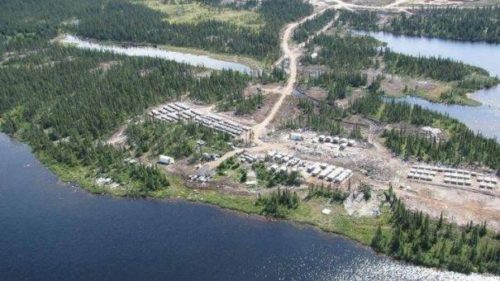

Standard Lithium recently announced the successful start-up of the industrial-scale Direct Lithium Extraction Demonstration Plant at Lanxess’ South Plant facility in southern Arkansas (the “Site”) on May 19, 2020. This plant, using LiSTR Direct Lithium Extraction technology, had been successfully commissioned on May 15m 2020 and is now operating on a 24/7 basis, extracting lithium directly from Lanxess’ tail brine of their bromine operations. Standard Lithium is now involved in systematic optimization in order to fine-tune the plant, which is a highly automated, three-story demonstration plant including an integrated office, control room and laboratory, and investigate how performance can be improved further. The most important features of the technology are, per the news release:

- Produces lithium chloride (LiCl) directly from un-concentrated raw brine;

- Reduces recovery time from months to less than a day;

- Eliminates the massive environmental footprint of evaporation ponds;

- Returns virtually all water to the source aquifer;

- Not affected by weather conditions;

- Vastly increases recovery efficiencies to as much as >90%; and,

- Unlocks large-scale unconventional brine resources.

The demonstration plant is capable of an annual production of between 100-150 tonnes per annum of lithium carbonate equivalent (LCE). To be clear, the LiSTR demonstration plant extracts lithium from the LANXESS tail brine stream and produces a high purity lithium chloride solution (LiCl) similar to the output of the evaporation ponds process but much faster, done in hours instead of many months. The LiCl will be sent off site and converted via a third party to battery quality, 99.5% purity lithium carbonate (Li2CO3). The commercial operation would incorporate an onsite Li2CO3 conversion plant. Standard Lithium is working on their own Li2CO3 technology called “SiFT”. The SiFT technology utilizes processes from the pharma industry and includes artificial intelligence and robotics to self-optimize the crystallization process. A news release in March announced that a prototype pilot plant produced a better than 99.9% purity Li2CO3.

Depending on the success of testing, either the SiFT plant or a standard plant will be constructed after the construction decision has been made.

In the meantime, the company is actively monitoring the COVID-19 pandemic and working closely with Lanxess to implement preventative measures at the site to safeguard the health of its employees and contractors. This results for example in funny site visit pictures like this:

Some of the measures being put into place include:

- Continuing operations at the site with the minimum staff present on site as required;

- Screening all contractors and external visitors to site for risk factors, as well as employees returning on shift change;

- Requiring employees who show symptoms or are in close contact with someone with symptoms to stay home from work;

- Suspension of all international travel and requiring employees returning from travel outside of the USA or Canada to self-isolate for the government recommended 14-day self-quarantine period;

- Implementing work-from-home practices where possible, including ongoing process engineering and optimisation work at the company’s LiSTR demonstration plant;

- Reducing in-person meetings and transitioning to videoconferencing where possible, as well as restricting any large gatherings;

- Enhanced cleaning and disinfecting protocols at the site on hard surfaces and especially at touch-points; and,

- Promoting personal preventative measures, such as frequent handwashing, and increasing awareness of social distancing practices.

According to CEO Robert Mintak, the impact of COVID-19 on the project has been managed exceptionally well with the technical team in Canada working virtually with the operations team in Arkansas. The impact to the timeline has been about 8 weeks, but compared to their peers who have been largely stalled or halted during the pandemic, Standard was able to push further ahead. A PFS that has been planned has been impacted by the travel ban. A release date will not be certain until international travel returns to somewhat normal.

I feel this is very reasonable, and even in line with normal project/study delays across the board of junior mining companies. The real outbreak of COVID-19 in March didn’t leave the Standard Lithium chart unharmed as can be seen here:

Looking in hindsight, the mid-March panic was a perfect buying opportunity, but many were probably expecting much more bad news, or a limited dead cat bounce at best, as the US, as the leading economic power, was gearing up to become the epicenter of the pandemic, with a president who initially denied a crisis and compared COVID-19 with the flu. The difference is there is a vaccine against influenza, and not against COVID-19. However, the virtually unlimited financial support programs from the central banks and governments seemed to provide sufficient oxygen for the markets, resulting in strong and lasting recoveries of indices and almost all individual stocks. For now, Standard Lithium has fully recovered and more, reaching highs not seen since Q4, 2018, and is working towards the all-important technology proof of concept, the consumation of the JV with Lanxess and a final investment decision.

As a reminder: this demonstration plant is roughly designed at 1/60 scale of the target production capacity of the first phase of commercial production, and should provide sufficient testing data this quarter for a planned upcoming Pre-Feasibility Study (PFS), and if the testing is successful and the JV formed it should be a straight path for the contempleted phased commercial production development after the investment decision would have been made by Lanxess.

The base case economics used to indicate a pretty robust lithium project, at a capex of US$437M an operation can be constructed with an after-tax NPV8 of US$989M and an after-tax IRR of 36%, based on an average long term LCE price of US$13,550/t. However, we are nowhere near such lofty price levels anymore unfortunately. In this useful article of Matt Bohlsen on Seekingalpha we can find a monthly update on lithium pricing which I find to be very useful when doing due diligence on lithium companies: Fastmarkets quotes an LCE price of US$7,500/t (coming down from US$8,750/t in February), and lithium hydroxide prices of US$9,750/t in this useful article of Matt Bohlsen on Seekingalpha, Benchmark Mineral Intelligence (BMI) has April prices at US$6,582 for Li carbonate (coming down from US$7922/t in February), US$9,125 for Li hydroxide, and US$420 for spodumene (6%). What I find fascinating is that the hydroxide price gap with carbonate remains constant in absolute terms, resulting in a larger and larger relative difference, potentially indicating higher fees being calculated by converters in Asia.

The trend keeps following a downward path, including a new drop in April/May, probably caused by COVID-19 fall-out as can be seen here in this chart coming from Fastmarkets (paid for link, chart provided by Bohlsen on Seekingalpha.com):

As the lithium carbonate market seems to be oversupplied, and demand is weakening further due to COVID-19, the short term outlook isn’t particularly healthy. For the long term I have seen market scenarios contemplating US$9,000-10,000/t LCE, but we aren’t there yet. Therefore I again reworked the lithium sensitivity, where three scenarios are presented, the 20.9kt LCE pa (per annum) base case, and the hypothetical 30kt LCE pa expansion scenarios as I calculated them in my first article on the company:

A current US$7,228/t LCE price, which is roughly a midpoint of Fastmarkets and BMI estimates, would generate a hypothetical NPV8 of about zero, and a hypothetical post-tax IRR of 9.2%, which would render the project not economic, as lithium projects usually need an IRR of at least 25%. As the Lanxess project has one of the best economics for lithium projects around, almost no project is economic these days. These figures are based on 100% project ownership economics. As stated in the past, Lanxess is committed to provide project finance to the JV when testing and the PFS are successful for them, and Standard will probably be an estimated 30% JV partner (according to company documents filed on Sedar. I asked CEO Robert Mintak this, and other questions in the following short interview:

The Critical Investor (TCI): Thanks for taking the time to conduct this short interview. First I wanted to ask you for a quick update on several basic items. Could you tell us what your current cash position, after raising C$17.1M in Q4/2019-Q1/2020?

Robert Mintak (RM): We closed a non-brokered financing in February for just over $12M Canadian, which has allowed us to continue advancing the project, We have a team of roughly a dozen at the plant in El Dorado and a handful working in Canada. At the end of Q3 March 31, 2020 we had roughly $7M CDN which we are deploying strategically to achieve our immediate milestones while managing the runway.

TCI: Could you explain to us what optimization steps you and your team are undertaking, and to what kind of improvements these could lead, possibly in terms of NPV/IRR increase, or capex/opex decreases?

Without going into a lengthy description, the ongoing operations, testing and optimization steps are similar to any piloting stage. On the LiSTR process specifically we will be testing for effective lithium recoveries, concentration and purity, residence time in the loading, washing and stripping reactors, water and energy consumption and, adsorbent life cycle performance and reagent recovery and optimization.

TCI: When do you expect to get in publishable useful numbers on costs, finally showing commerciality of the proprietary extraction process, maybe not at current LCE prices but for example at US$10k/t levels?

RM: The price today of battery quality lithium carbonate is not the same as what is being reported. Pricing out of Japan and Korea is above $10K. We will be modeling the project economics based upon well thought and researched pricing models for battery quality (BQ) lithium over the next number of years. Covid-19 has had an impact on the sales of EV’s and other consumer goods, however the economy coming out the pandemic will be different than the economy prior. EV’s and renewable energy which includes stationary storage, have been prioritized as part of new era of dirigisme that is being displayed by many of the world’s largest economies. The lack of investment in the raw material supply chain, new lithium production, along with importance of localizing production and decoupling from China-centric critical supply will elevate the value of a US producing lithium asset.

TCI: What about the SiFT pilot processing plant, do you still anticipate delivery to the Arkansas site in Mid Q2, or did COVID-19 slow things down here as well?

RM: The SiFT plant is fully mechanically built and paid for. We will begin commissioning soon. Instead of shipping the plant to Arkansas as originally contemplated, because of the COVID travel restrictions we will commission the plant in Canada by shipping LiCl from Arkansas to Canada. The same results but this will save money and time. We will at some point, when travel returns to normal, ship the SiFT plant for installation in Arkansas.

TCI: When is the PFS expected, try to be as specific as possible?

RM: COVID travel restrictions will determine the PFS timing. The PFS will require site visits by several QP’s. With the current pandemic and other elements it would be out of place to provide a specific timeline.

TCI: If possible, could you indicate to the audience your expectations for PFS economics, as compared to PEA economics?

RM:The PEA that was released in Q3 2019 took a very conservative stance. We believe the data from the demonstration plant combined with some other key cost input efficiencies like reagent recovery will improve the already attractive project numbers by a healthy percentage.

TCI: As I mentioned in the paragraph before this interview, prices for lithium products have dropped off significantly, even rendering the project uneconomic. I know you are optimizing project economics, but a drop from US$10k being the minimum of being economic to US$7k nowadays is probably more than can be restored by optimization. How are you dealing with this, and more importantly maybe, do you know how Lanxess is dealing with this? Do they have a certain higher price scenario for the long term future in their heads, and will continue with a construction decision as long as a certain minimum LCE price will result in an economic project?

RM: As I mentioned earlier, I disagree with the sub $10K pricing scenario for battery quality lithium carbonate, and I state, regardless of the pricing today, the industry is going to be facing a day of reckoning in the near future for the lack of investment in new projects capable of producing battery quality lithium chemicals, not spodume concentrate, rather fully integrated lithium chemical production. This will likely result in a spike in pricing much like what we saw from 2015-18.

TCI: I read something in the PEA recommendations about adding a unit which could use direct raw brine, without using the tail brine of the Lanxess bromine operation. Is this still an option?

RM: The LiSTR process is not affected by bromine being present in the brine. So yes we are looking at the entire opportunity in south Arkansas which represents a much larger number than what was considered in the PEA

TCI: Do you have anything else to add for interested investors?

RM: The project is incredibly exciting and potentially disruptive for the industry. A number of companies have been promoting direct lithium extraction, black boxes and magic beads for years but the approach we have taken has been project focused and methodically executed. We now have an operating direct extraction plant while still pre-commercial, this is at a scale no one has ever done before. We are just at the starting line and things are going to get even more exciting as we go into the next phase.

Conclusion

After COVID-19, the world seems to have changed. Fortunately, Standard Lithium managed to raise C$12.1M right before things got serious, and commenced their demonstration plant after small delays. On the process side of things, the project is running quite smoothly despite COVID-19. On the lithium product pricing side, things don’t really cooperate. However, according to CEO Robert Mintak, real contract pricing for lithium products in Japan and South Korea, being major battery producers, is hovering close to US$10k which would still render the Lanxess project economic with an after-tax IRR of 25%, as one of very few lithium projects.

After COVID-19 restrictions being no longer necessary, Standard can complete their upcoming PFS, which will likely show improved economics. Directly after this, a Lanxess construction decision awaits.

I hope you will find this article interesting and useful, and will have further interest in my upcoming articles on mining. To never miss a thing, please subscribe to my free newsletter on my website www.criticalinvestor.eu, and follow me on Seekingalpha.com, in order to get an email notice of my new articles soon after they are published.

Disclaimer:

The author is not a registered investment advisor, and currently has a long position in this stock. Standard Lithium is a sponsoring company. All facts are to be checked by the reader. For more information go to www.standardlithium.com and read the company’s profile and official documents on www.sedar.com, also for important risk disclosures. This article is provided for information purposes only, and is not intended to be investment advice of any kind, and all readers are encouraged to do their own due diligence, and talk to their own licensed investment advisors prior to making any investment decisions.

Swiss Resource Capital AG

Poststrasse 1

CH9100 Herisau

Telefon: +41 (71) 354-8501

Telefax: +41 (71) 560-4271

http://www.resource-capital.ch

CEO

Telefon: +41 (71) 3548501

E-Mail: js@resource-capital.ch

![]()