HeavyDuty rotary encoders – the high precision heavyweight champions

Dockside cranes that unload thousands of tons of shipped goods daily. Conveyor systems that carry thousands of tons of mined ore from mining plants across many kilometers. Elevators that carry thousands of people daily. Automated production lines on which automobiles in various assembly stages are transported. Lifting bridges with a total weight of 1000s of tons that can carry several trains at once and that are lifted many times per day to allow ships to pass. These and many other application scenarios constitute the world of HeavyDuty rotary encoders – anytime difficult tasks must be reliably carried out under difficult conditions and over the long term.

The term has been linked to Hübner Berlin since the 1950s, when the company established the supreme rotary encoder class. Since that time, Hübner Berlin, which today belongs to sensor specialist Baumer, has continuously improved its products and is still considered the expert provider of HeavyDuty rotary encoders. But what do we mean when we talk about HeavyDuty products? After all, the term is not legally protected or regulated by a standard. "Heavy duty" as such simply means hard-wearing. A possible reason why some people think that HeavyDuty rotary encoders are simply encoders with thick housing walls and rust protection. In reality, the term denotes much much more.

What makes a rotary encoder "HeavyDuty"?

To Baumer Hübner, "HeavyDuty" is an all-encompassing performance promise. First of all, this means that such a rotary encoder never lets its user down, even under the most difficult conditions. And secondly that these heavyweights work as precisely as "small" rotary encoders for an extended period of time. HeavyDuty rotary encoders from Baumer Hübner accomplish this through four characteristics:

Precision: A rotary encoder must deliver reliable signals to allow users to precisely control and regulate drives and generators. Plant control systems utilize these signals for speed monitoring of drives or for position feedback of machine parts. To controllers, this information is the only way to get informed and intervene, for example, if a drive exceeds or falls below a defined speed limit. Since the machines and systems are usually very big – dock cranes, bucket-wheel excavators, rolling mills, garbage shredders – they could give the above-mentioned impression that precision does not matter much. That is a mistake. Particularly because heavy loads are moved with great force, small measuring errors could have extensive consequences, for example, when setting down a container weighing several tons.

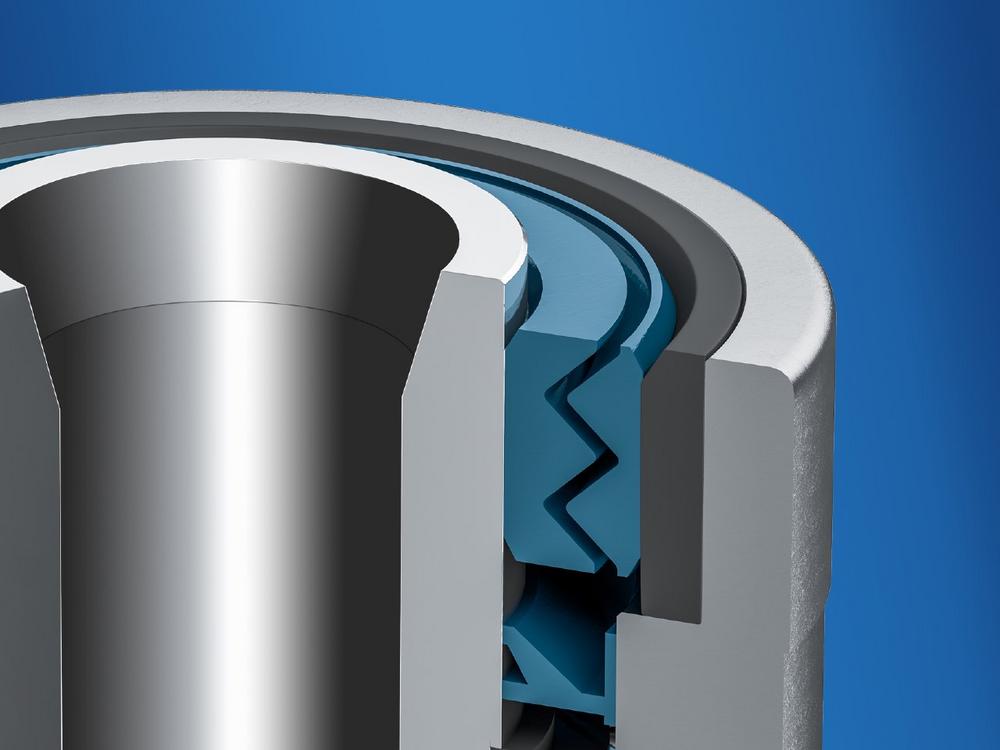

Mechanical robustness: a HeavyDuty rotary encoder must be so resilient that it can withstand hard shocks, vibration, and forces on the rotary encoder shaft for many years. Exchanging rotary encoders is expensive, not because of pricing but because of installation in places difficult to access and the system being down for the time of exchange. HeavyDuty rotary encoders are distinguished by several characteristics: Double-sided bearing setup with generously dimensioned, largely spaced bearings at both shaft ends to compensate axial and radial load, robust and thick-walled housings, and durable protection of the inside components against shocks and vibration.

Tightness: HeavyDuty rotary encoders are usually deployed in dusty, soiled, and damp environments. For this reason, the HeavyDuty encoder housing must be well sealed, especially at critical, neuralgic points – the shaft and electrical connections. Further, in terms of potential contact to chemicals or salt water, a good corrosion protection through appropriate housing materials and coatings is mandatory.

Electrical robustness: HeavyDuty rotary encoders must be immune against electromagnetic fields. These are generated by live, unshielded cables routed nearby, which is a quite common situation in many applications. Without adequate shielding, the electronics in the rotary encoder might be destroyed or provide erroneous measuring signals. Another point are shaft currents caused by potential differences. They may burn the bearing lubrication, which results in bearing destruction. For all these reasons, the inside electronics of HeavyDuty rotary encoders must be electrically isolated from the ambiance of operation.

Whether absolute or incremental – above the standard

As described above, there are diverse application areas for HeavyDuty rotary encoders. Therefore, the HeavyDuty portfolio of Baumer Hübner is just as diverse with many variations of incremental or absolute rotary encoders. The HOG 10 / POG 10 is the reference device among incremental rotary encoders. The rotary encoder HOG10 provides even more features only offered by Baumer that can enormously increase the fitting accuracy, as shown by the following two examples:

HeavyDuty rotary encoders are usually deployed in harsh environments with exposure to dust, moisture, and chemicals and therefore require powerful protective seals. But not all seals are equal. This is why HOG 10 is available with several sealing concepts for optimum protection in oily, damp, or dusty environments, for use in tropical and offshore climates, in cement works or other demanding environments. There are, for example, reliable and absolutely wear-free seals that endure impacts by coarse and fine-grained solids and whose sealing components function with absolute wear and tear durability. In addition, sealing free from friction prevents any performance loss. Such a sealing concept is most efficient and less energy-consuming at high speed.

Since HeavyDuty rotary encoders are generally deployed in giant installations, signal transmission must often cover a distance of 100 meters or more. For this reason Baumer attaches great importance to excellent signal quality and high-power outputs using short-circuit proof power transistors. There are even product variants that are capable of a distance up to 550 meters. Where this is not sufficient, fiber optic cables ensure noise-immune signal transmission over a distance of 1.5 kilometers.

Similarly, absolute rotary encoders such as the HMG 10 / PMG 10 also have special features beyond those of standard encoders: for example, providing precise position outputs via PROFINET. Frequently, incremental signals are also required for speed feedback in absolute rotary encoders, which is why absolute HeavyDuty encoders deliver speed signals in addition to the absolute position, for example as HTL or TTL, via serial digital interfaces such as SSI or fieldbus. Some product variants even integrate a speed switch for limit speed information via switching output.

Flexible solutions for every application

There are various mounting options, whether as hollow shaft designs (through or non-through), cone shaft, or solid shaft with optional EURO flange B10 connection. If required, HeavyDuty rotary encoders, speed switches, and tacho generators can be combined in one single robust, space-saving unit to provide varied types of output signals measured at a single drive shaft all at once. Large encoders such as HOG 16 / 22 /28 from Baumer are used for maximum speed limit monitoring of large drive shafts under the most difficult conditions, such as in coal dust, corrosive air, or in the burning heat of steel mills.

Due to the many available options, interested buyers should best check first together with our experts which HeavyDuty rotary encoder is appropriate for the intended application. No matter what product you opt for in the end – above-average precision and durability are always part of the package of HeavyDuty rotary encoders from Baumer Hübner.

The Baumer Group is one of the worldwide leading manufacturers of sensors, encoders, measuring instruments and components for automated image processing. Baumer combines innovative technologies and customer-oriented service into intelligent solutions for factory and process automation and offers an unrivalled wide technology and product portfolio. With around 2,700 employees and 39 subsidiaries in 19 countries, the family-owned group of companies is always close to the customer. Baumer provides clients in most diverse industries with vital benefits and measurable added value by worldwide consistent high quality standards and outstanding innovative potential. Learn more at www.baumer.com on the internet.

Baumer Holding AG

Hummelstrasse 17

CH8501 Frauenfeld

Telefon: +41 (52) 72811-55

Telefax: +41 (52) 72811-44

http://www.baumer.com

Baumer MDS GmbH

Telefon: +49 (7771) 64740

E-Mail: anschulz@baumer.com

MEPAX

Telefon: +34 (619) 0277-78

E-Mail: m.depablos@mepax.com

![]()