OPC UA for production without machine downtime

The Sitraplas team, over 40 employees strong, works in state-of-the art production and laboratory facilities to quickly and reliably implement individual solutions. Their compounds are used by customers all over the world in challenging applications in the automotive, electrical engineering, and electronics industries, among others.

Equipment downtimecosts time and money

Unplanned downtime is a nightmare for every company, but especially for continuous production facilities. Troubleshooting in the event of equipment failure is not only tedious and complex, but also very expensive. In turn, the lost time and resources associated with downtime can negatively impact both productivity and the competitiveness of the company.

Identifyerrors in real time via thecompany network

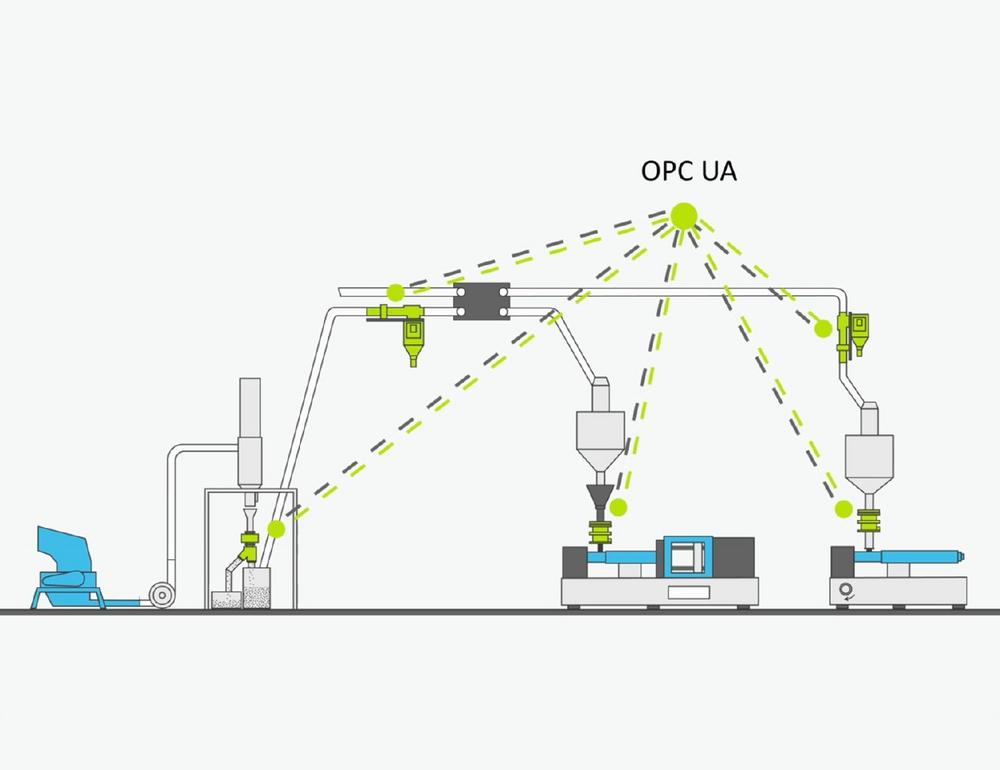

An important component of Industry 4.0 is the exchange of data during production. To this end, companies are increasingly adopting Open Platform Communications Unified Architecture (OPC UA) as the industry standard for machine communication protocol. From production to servicing, OPC UA helps to optimize many aspects of plastics processing. By minimizing losses of time and products, OPC UA helps to maximize added value and product quality.

When metal separators are networked with plastic processing machines, the flow of information between machines can be monitored. Should any system error occur, the system operator instantly receives a notification and can address the issue immediately. A comprehensive overview of the different parameters under which the equipment is operating runs in real time over the company network.

Improvedsystemavailability and minimal downtime

The implementation of OPC UA communications protocol has had many benefits for Sitraplas. “Since we have been using OPC UA, we’ve had minimal maintenance and downtime,” says Tim Hencken, Managing Director of Sitraplas GmbH. “System availability has seen considerable improvements.”

Sesotec is among the very first providers of intelligent inspection and sorting systems for use in the plastics, food, and recycling industries. These innovations are testament to our commitment to customer satisfaction and Industry 4.0.

Sesotec is one of the leading manufacturers of machines and systems for contaminant detection and material sorting. Product sales primarily focus on the food, plastics, chemical, pharmaceutical, and recycling industries. Sesotec’s global presence includes subsidiaries in Singapore, China, USA, Italy, India, Canada and Thailand, and more than 60 partners all over the world. The Sesotec group presently has 540 employees.

Sesotec GmbH

Regener Strasse 130

94513 Schönberg

Telefon: +49 (8554) 3080

Telefax: +49 (8554) 2606

https://www.sesotec.com/emea/de?utm_source=pressebox&utm_medium=link&utm_campaign=corp&utm_term=de

Marketing & PR

Telefon: +49 (8554) 308-2100

Fax: +49 (8554) 2606

E-Mail: brigitte.rothkopf@sesotec.com

![]()