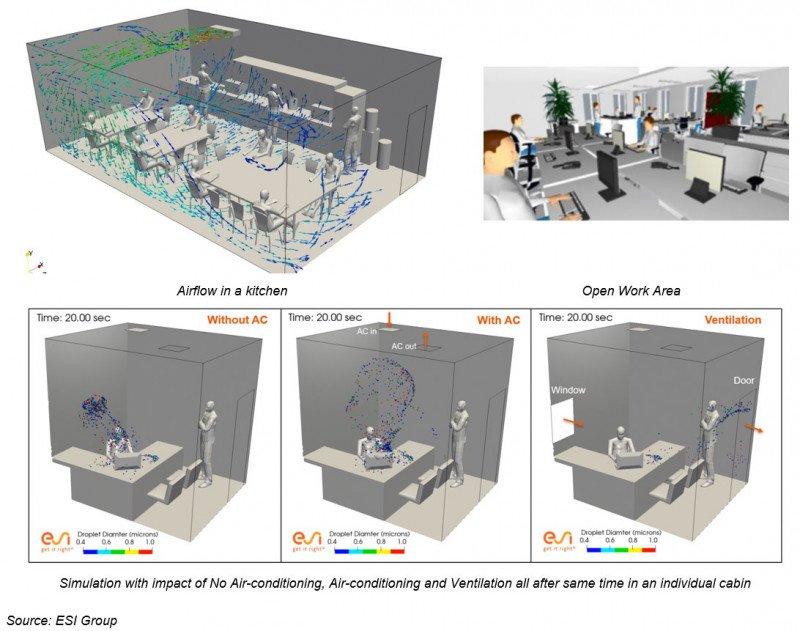

ESI Group helps manage the risk of COVID- 19 contamination in the workplace

ESI’s experts, throughout the United States, Asia and Europe, have collaborated with various organizations, including the Pacific Northwest National Laboratory (PNNL), to investigate different scenarios to demonstrate the effect of occupant proximity, ventilation systems and contamination avoidance unique to each office and plant environment.

The customized simulations that were carried out provided answers to the following questions:

- How can open spaces and offices be rearranged to be in line with the rules of social distancing?

- How to adapt air-conditioning ventilation and fan speed to create air curtains and protect against aerosol penetration?

- How does the opening and closing of doors affect ventilation and air movement?

- Establish rules for travel and employees’ gatherings based on fresh air circulation.

- Locate, avoid and clean "dead spots" where aerosol particles could linger.

"The Coronavirus crisis, that we have all been experiencing for several months, is distressing a lot of habits and has resulted in new issues to be addressed by companies. Employee safety has always been key, but when the danger is invisible yet circulating in the air, the topic appears to be more complicated and crystallized. Just like other industrial and technological players, we seek to provide as many people as possible with solutions to help rebuild, secure and reassure. Simulation is an ideal tool that enables testing a very large range of scenarios without endangering anyone. Our expertise in material physics, Multiphysics and more precisely in fluid mechanics has allowed us to create realistic scenarios of droplet behavior in more or less enclosed and ventilated spaces. We are pleased to provide our input and to continue being faithful to our values: being as close as possible to our customers to help them achieve their goals, including the most challenging ones.", commented Anshul Gupta, COO at ESI India Business Operations on behalf of his team leading this project.

Founded in 1973, ESI Group is a leading innovator in Virtual Prototyping solutions and a global enabler of industrial transformation. Thanks to the company’s unique know-how in the physics of materials, it has developed and refined its advanced simulation capabilities since its inception. Having identified gaps in the traditional approach to Product Lifecycle Management (PLM), ESI has introduced a holistic methodology centered on industrial productivity and product performance throughout its entire lifecycle, i.e., Product Performance Lifecycle™, from engineering to manufacturing and in operation. Present in more than 20 countries, and major industrial sectors, ESI employs 1200 high-level specialists. In 2019, its turnover was 146M€. ESI is headquartered in France and is listed on compartment B of Euronext Paris.

Engineering System International GmbH

Siemensstr. 12

70565 Stuttgart

Telefon: +49 (6102) 2067-0

Telefax: +49 (6102) 2067-111

http://www.esi-group.com

Telefon: +49 (6102) 2067-183

E-Mail: Egon.Wiedekind@esi-group.com

![]()