Thanks to ROMIRA’S PVD innovations

The Physical Vapor Deposition (PVD) process has become increasingly more important in recent years due to its ecological advantages over the galvanic process. ROMIRA has now developed a product range that further optimizes the PVD process, providing new design possibilities and reducing process steps: The innovative PC and polyester based ROMILOY® types allow the PVD layer to be applied so thinly that when the object is illuminated from behind, the light shines through. Backlighting makes metallic-looking surfaces translucent – opening up countless new design and individualization possibilities. This enables logos, lettering or pictograms, for example, to be highlighted in a highly expressive manner, simply by applying a mirror-inverted sticker.

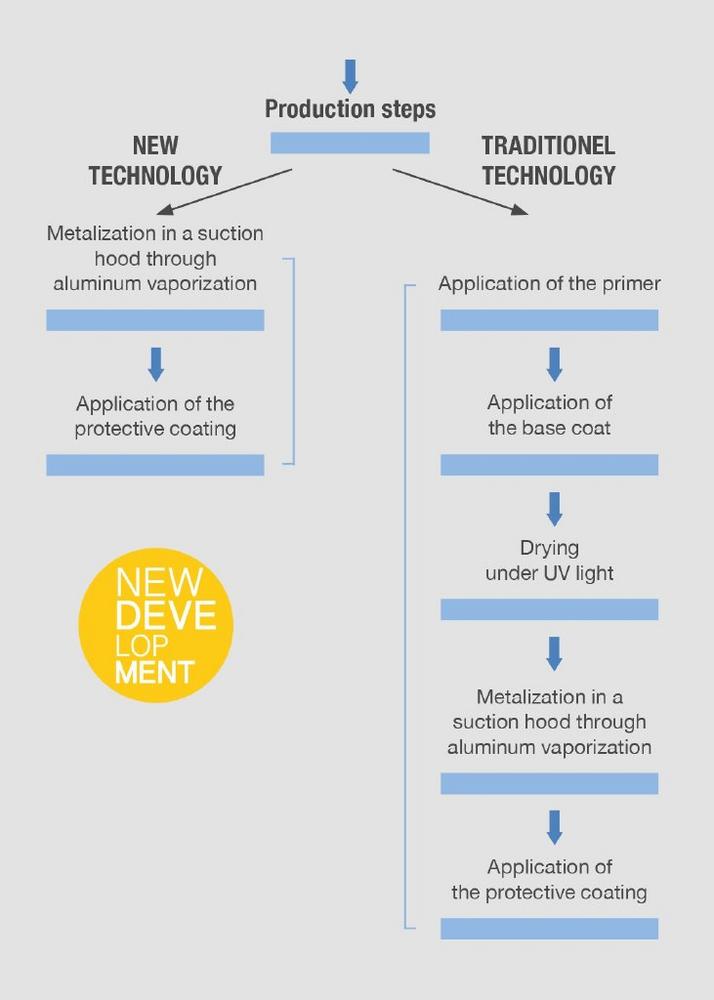

The new developments from ROMIRA have even more to offer: In addition to the design added value, the ROMILOY® products are also impressive in that they reduce the PVD process from four to two steps, as primer and base coat can be eliminated. Fewer work steps, less material equals less CO2 emissions!

Customers are already very enthusiastic about the innovative product portfolio, which offers new, more individual and environmentally sustainable design possibilities.

About the ROMIRA GmbH:

The ROMIRA GmbH was founded in 1990 and is an affiliated partner within the ROWA GROUP. As part of this strong combine, ROMIRA sets standards for technical plastics with its profound competence and synergetic know-how.

ROWA GROUP Holding GmbH

Siemensstraße 1-9

25421 Pinneberg

Telefon: +49 (4101) 70606

Telefax: +49 (4101) 706203

http://www.rowa-group.com

ROMIRA GmbH

Telefon: +49 (4101) 706-303

E-Mail: s.guzielski@romira.de

![]()