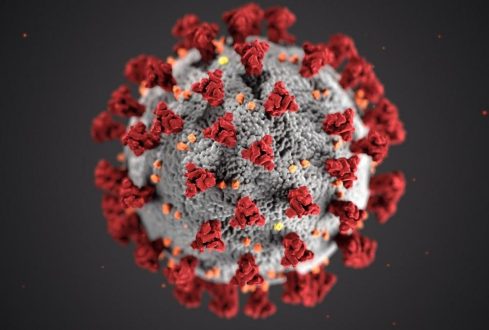

Workshop: COVID-19. Minimize the risk of infection & increase confidence in safety.

The analysis of infection outbreaks have shown that keeping 1,5 m distance to other people does not always protect from becoming infected. Interventions like wearing masks or costly structural measures like acryl glass barriers are not always necessary or effective.

Validated CFD-tools, like OpenFOAM, allow us to simulate and visualize the dispersion of aerosols under various conditions. In turn, digital simulation enables us to assess the effectiveness of interventions. The opensource nature of OpenFOAM provides the unique framework to generate knowledge about the containment of the spread of the virus in a broad community with increasing speed.

This mini-workshop is aimed at:

- Stating the “need for simulation” based on OpenFOAM® (CFD) for aerosols and air-movement

- Assessing the current status for quickly developing and validating useful measures in protecting people from being infected

- Identify end-users (stakeholder case studies) who will benefit from qualitative measure to make better inform choices for ventilation, placements and distancing in enclosed spaces

Agenda:

Keynotes

1.00 – 1.20 pm Dr. Gerhard Scheuch “Airborne transmission of SARS-CoV-2 virus and consequences for infection control”

1.20 – 1.40 pm Prof. Kevin Maki “Disease transmission through aerosol transport on an urban bus”

1.40 – 2.00 pm Fred Mendonca "CFD verification & validation of underlying physics regimes"

Discussion with Panelists

2.00 – 2.40 pm Moderated discussion and interaction with attendees and all keynote speakers. Audience is invited to bring in their challenges, problem cases & initiatives.

Practical Exercise

2.40 – 4.00 pm Hands-on to the environmental simulation with a prepared example ventilation (individual login to Cloud and remote applications)

Who should attend?

- Operations managers, operators, production planners, crisis managers

- Facilities managers of urban spaces (offices, assembly plants, restaurants, theatres, common waiting areas, stadiums, shopping centers, etc. …) who would benefit from simulation

- Simulation professionals who have an interest in ventilation management and containment of airborne aerosol virus transmission

Founded in 1973, ESI Group is a leading innovator in Virtual Prototyping solutions and a global enabler of industrial transformation. Thanks to the company’s unique know-how in the physics of materials, it has developed and refined its advanced simulation capabilities since its inception. Having identified gaps in the traditional approach to Product Lifecycle Management (PLM), ESI has introduced a holistic methodology centered on industrial productivity and product performance throughout its entire lifecycle, i.e., Product Performance Lifecycle™, from engineering to manufacturing and in operation. Present in more than 20 countries, and major industrial sectors, ESI employs 1200 high-level specialists. In 2019, its turnover was 146M€. ESI is headquartered in France and is listed on compartment B of Euronext Paris.

Engineering System International GmbH

Siemensstr. 12

70565 Stuttgart

Telefon: +49 (6102) 2067-0

Telefax: +49 (6102) 2067-111

http://www.esi-group.com

Telefon: +49 (6102) 2067-183

E-Mail: Egon.Wiedekind@esi-group.com

![]()