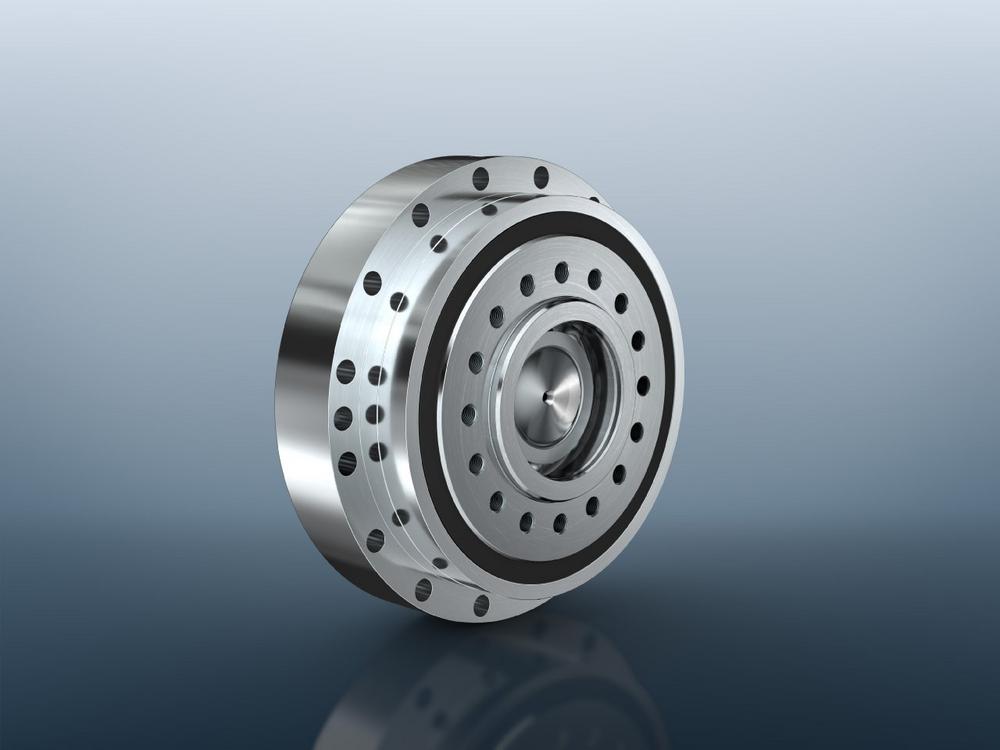

New generation of modular precision gears

Based on the proven Fine Cyclo Technology* – the basis of all Sumitomo Precision Gears – this new development now offers several significant advantages. The most important innovation – when compared to competitor units – is the significantly increased torque per unit size. The number of sizes in the series line up has also been significantly expanded in response to customer demand for more individuality and new sizes have been developed accordingly.The DA series gearboxes are now approx. 8% smaller in diameter and 5% shorter in length. Despite this reduction in size, performance has been increased by approx. 20% across the range, giving a triple benefit. More power, less space and conversely less weight.

The noise levels of the DA series have also been optimised and significantly reduced. This is an important factor when people are working near the drive applications, as for example in the medical field.

With these products, Sumitomo Drive Technologies also aim to expand the demands of major customers in the fields of robotics, machine tools, medical device technology and food & beverage applications. The experience gained from long established and existing applications has contributed significantly to the original design of the DA series and subsequent product developments. For large quantities the price/performance ratio has a profound affect where, the single-stage gearboxes of the DA series offer significantly lower manufacturing costs when compared to standard two-stage gearboxes, of the same torque class.

Plug & Play Gearboxes

All sizes of the DA series can be easily integrated into systems. The motor shaft is connected to the gear unit by way of a clamping ring which offers a friction connection eliminating the necessity for the customer to adapt the motor connection to suit. For each of the DA series sizes, the connection of several motor shaft diameters is possible, allowing the use of motors from many different manufacturers. The connection geometry does not require a complex installation, nor does it require an adjustment of the drive shaft by the customer. Sumitomo are therefore able to offer a remarkably simple installation of both the gearbox and the motor. Thanks to the partnership with the motor specialist Lafert, Sumitomo can also offer servo motors and controllers from a single source.

* The CYCLO principle was already developed by Lorenz Braren at the beginning of the twentieth century and is still unrivalled today. Cyclo gears are eccentric gears without gear wheels. Inside the gear unit, cam discs transmit the torque by rolling. The eccentric drives a cam disc with n cam sections, which rolls in a fixed pin ring with n+1 pin. While the cam rotates clockwise within the pin ring, it simultaneously moves counterclockwise around its own axis. When the cam sections roll over the bolts one after the other, the cam disk moves only one cam section further per full rotation of the drive shaft. This results in rotation in the opposite direction to the drive with reduced speed. The transmission ratio to slow is determined by the number of cam sections of a cam disk. Each cam has one less cam section than there are pins in the pin ring. Therefore, the transmission ratios are equal to the number of cam sections of the cam. The reduced rotary motion of the cams is transmitted to the output shaft via pins that engage in the holes of the cams. Usually a kit consists of two cams with double eccentric. This results in smooth, vibration-free operation despite the higher torque.

Sumitomo entered a technical alliance with Lorenz Braren in 1938. Since then, his invention has formed the basis for Sumitomo’s most important products and their further developments on the market and still confirms the company as a technology leader today, as cyclo gears are successfully used worldwide, for example in industrial robots and transfer machines. The newly developed backlash-free DA series has three smooth cycloid disks arranged in a balanced system.

This new gear unit series as well as selected products from the portfolio of the drive specialists Sumitomo together with Invertek and Lafert can be found on emeia.sumitomodrive.com/en-de.

Under the umbrella brand Sumitomo Drive Technologies, Sumitomo Heavy Industries combines all companies, brands, and products of the Power Transmission & Controls Group worldwide. The brand stands for a global product portfolio of gear boxes, gearmotors, precision gearboxes, industrial gearboxes, and centrifugal drives of the most varied designs and for over 140 years of expertise. With the acquisition of the Belgian company Hansen Industrial Transmissions in 2011, the acquisition of the Italian motor manufacturer Lafert Group in 2018 and the acquisition of the Welsh motor control specialist Invertek Drives, the long-established Japanese group is continuously expanding its expertise as a manufacturer of complete drive train solutions. With 10 production facilities, over 30 assembly plants, 250 sales offices and almost 7000 employees on five continents, the company has an extensive network to meet regional customer requirements.

Sumitomo Drive Technologies

Cyclostr. 92

85229 Markt Indersdorf

Telefon: +49 (8136) 660

http://www.sumitomodrive.com

Media relations

Telefon: +49 (9776) 7096959

E-Mail: bach@bach-kommunikation.de

![]()