Sealing underbody battery housings efficiently, precisely, and safely

The battery housings installed in the car underbody are seamlessly sealed with the room temperature cross-linking 2-component polyurethane foams from the SONDERHOFF FERMAPOR K31 product family. They protect the electric batteries against moisture, corrosion, and dust. They also dampen vibrations and are resistant to temperature and chemicals on the polyurethane material specifics. Protection against these influencing factors helps to improve the long life of the E-batteries.

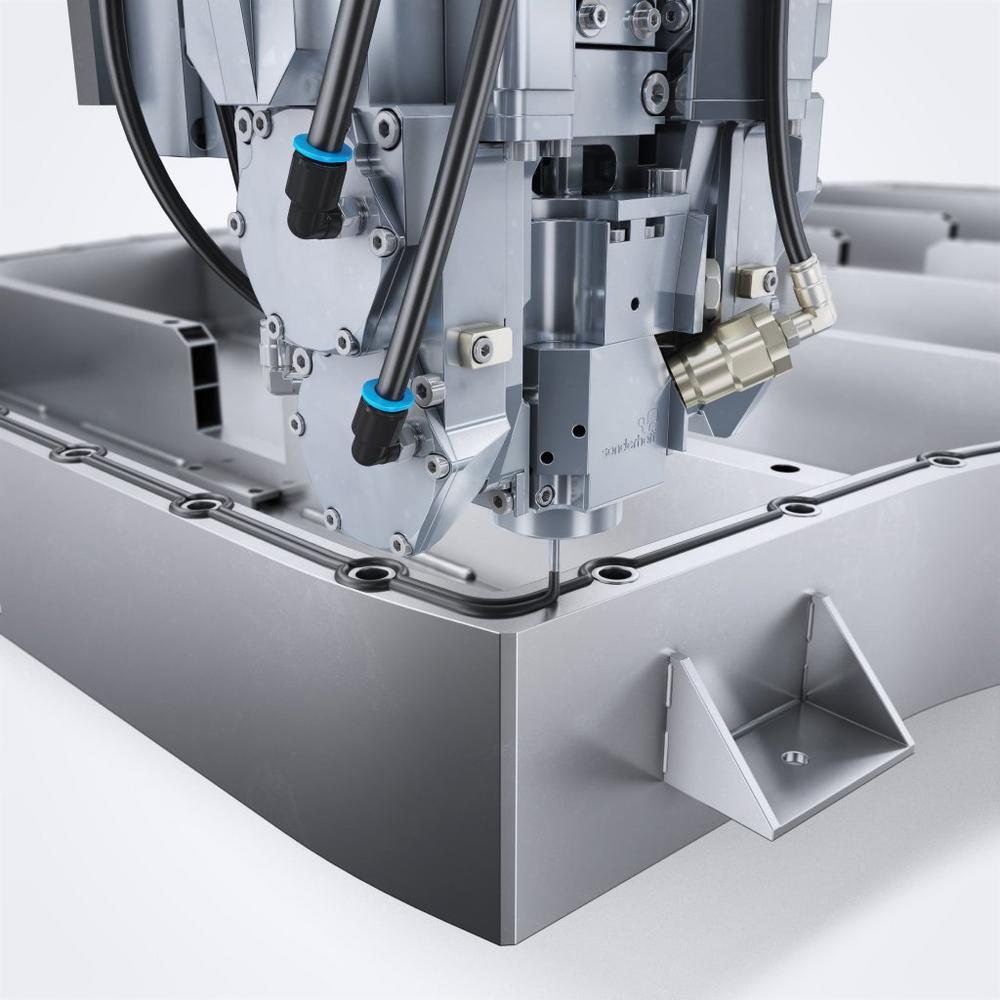

The die-cast aluminum housings for holding the electric batteries are sealed efficiently, precisely, and securely using FIPFG (Formed-In-Place-Foam-Gasket) technology. The CNC-guided mixing head of the SONDERHOFF mixing and dosing machine moves along the housing geometry and applies the 2-component polyurethane sealing foam SONDERHOFF FERMAPOR K31 with precise contours. After foaming, a seamless foam gasket is produced which cures at room temperature.

The elastic foam cell structure of the seal is compressed when the battery housing cover is screwed tight. Thus, the housing and cover are sealed to each other. The excellent resetting ability of the foam sealing allows the housing to be opened and re-closed repeatedly for maintenance purposes. At the same time, the sealing effect of the housing seal is maintained by the consistently good compression of its foam structure. The housing is sealed, and the batteries are protected against splash water and weather influences.

With the SONDERHOFF SYSTEM SOLUTIONS, from material systems to mixing and dosing equipment to contract manufacturing, Henkel offers a one-stop solution. Henkel’s experts provide application technology advice from the design phase of the components through to fully automated material application using Formed-In-Place (Foam-Gasket) technology in series production. The tailor-made automotive solutions with products from the SONDERHOFF portfolio range from foam gaskets based on polyurethane or silicone and systems for bonding and potting to mixing and dosing machines for automated material application on industrial components. Alternatively, Henkel also takes over the sealing, bonding, or potting of components in contract manufacturing.

We make it happen!

About Henkel

Henkel has a balanced and diversified global portfolio. With strong brands and leading innovations and technologies across three business units – Adhesive Technologies, Beauty Care and Laundry & Home Care – the company has market-leading positions in both consumer and industrial goods businesses. Henkel Adhesive Technologies is the global market leader in the adhesives sector, for example, and the Laundry & Home Care and Beauty Care business units also hold leading positions in many markets and categories. Established in 1876, Henkel can look back on a 143-year history of successful business performance. In the 2019 financial year, Henkel generated sales of 20.1 billion euros and net earnings of 3.2 billion euros. The group employs more than 52,000 people worldwide, forming a diverse team bound together by a strong corporate culture, a shared corporate objective, and common values. Henkel’s progress and performance in sustainability is confirmed by numerous international rankings and ratings. Henkel preferred shares are listed in the German stock index DAX. Further information is available at www.henkel.de.

SONDERHOFF SYSTEM SOLUTIONS is a technology portfolio of Henkel AG & Co. KGaA for customized automated sealing, bonding and potting solutions using Formed-In-Place-(Foam-Gasket) technology. The spectrum ranges from material systems to dosing systems (equipment) and contract manufacturing (subcontracting). Customers can choose between our complete package of products and services from a single source or the individual solutions that suit their needs. Ideally, our cooperation with the customer starts at an early stage of product development and extends over the entire product life cycle. In doing so, we draw on more than 1,000 self-developed formulations based on polyurethane, silicone or PVC, knowledge that has been patented several times and many years of experience. The products and services of the SONDERHOFF portfolio are available globally: from application technology consulting for the selection of the appropriate process technology, machine and material systems for the customer, through sampling and training, to the business management considerations of outsourcing complex processes to SONDERHOFF contract manufacturing. The spectrum here ranges from the sampling of prototypes and small series to serial production on a production scale. Further information can be found at www.sonderhoff.com.

„Sonderhoff Automation Solutions“ – Henkel AG & Co. KGaA

Henkelstr. 67

40589 Düsseldorf

Telefon: +49 (211) 797-3533

Telefax: +49 (221) 95685-599

http://www.henkel.de/

Teamleiter Marketing

Telefon: +49 (221) 95685285

Fax: +49 (221) 95685599

E-Mail: F.Kampf@sonderhoff.com

![]()