NSK shows its competency in ultra-fine positioning

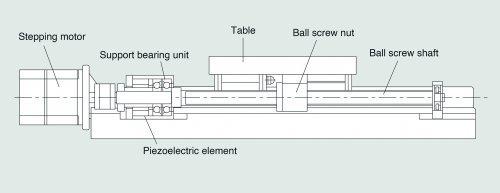

The market demand for positioning mechanisms with nanometre accuracy continues to expand across sectors that include semiconductor manufacturing equipment, biotechnology, optical communications devices and micro electro mechanical systems (MEMS), to list but a few. Fine positioning stages intended to meet these requirements have been available for some time, typically comprising a ball screw, stepper motor and piezoelectric element. However, these solutions generally lack stiffness and fall short of the ultra-high resolution needed at high speeds.

NSK’s nanopositioner overcomes these challenges. Featuring a proprietary ball-screw fixed-end bearing unit with piezoelectric element, the device provides fine positioning at nanometre accuracy and high speeds without compromising mechanical rigidity. Maximum speed is 72 mm/s, while resolution is 5 nm and positioning accuracy is ±15 nm. Among the major differentiating features of the nanopositioner is its configuration and system structure. Conventional fine positioning stages use a stacked piezoelectric element as a form of piezoelectric actuator, but this design is vulnerable to tension, moment and radial forces. The deployment of compression springs can counter this effect, but they lack adequate rigidity and can hamper high-speed operation.

Instead, the NSK nanopositioner incorporates a piezoelectric element in a ball screw fixedend bearing unit. Mounting the piezoelectric element on the same shaft as the preloaded bearings means unwanted moment or radial forces do not occur. In addition, the provision of bearing preload as compression force on the piezoelectric element avoids tension, while rigidity is uncompromised.

The nanopositioner offers easy application in XYZ positioning stages. By way of example, the device is at the heart of a proven NSK micro-manipulation system for fine positioning. With the ability to manipulate items as small as a single cell, the system is ideal for a variety of medical science and biotechnology applications, while nanotechnologists find the system useful in assembling microscopic tools. Driven by a rotary motor, the nanopositioner provides the required fine-motion positioning control of various set-ups and micro-manipulators, ensuring ease of operation and the highly accurate movement of various stage attachments.

Two types of NSK nanopositioner are available: the M series featuring a compact singleaxis stage; and the CD series with dual-axis XY table.

NSK Europe Ltd. is the European organisation of the Tokyo-based bearing manufacturer NSK, which was founded in Japan in 1916 and today employs nearly 31,000 people in its worldwide operations. The products and solutions provided by the industrial and automotive supplier can be found wherever things move. In addition to nearly all types of rolling bearings, the company’s portfolio includes housed bearings, linear technology, wheel bearing units, transmission and engine bearings and steering systems. The company is oriented to perfection in all of its business activities. Its aim is quality leadership in its industry, which it strives for through a continuous process of improvement, excellent product development, optimised production processes and customer-oriented service processes. In fiscal year 2019, the more than 4,400 employees of NSK Europe Ltd. generated sales of over € 920 million.

www.nskeurope.com

NSK Deutschland GmbH

Harkortstrasse 15

40880 Ratingen

Telefon: +49 (2102) 4810

http://www.nskeurope.de

Telefon: +49 (2102) 4811280

E-Mail: pilath-m@nsk.com

Telefon: +34 (600) 780-385

E-Mail: k.matsuo@mepax.com

![]()