Pressurized HMI in Ex Zone 1 at an automotive supplier

Different solutions for the potentially explosive area like, for example, overpressure solutions, powder filling or intrinsically safe systems could not be realised for technical and or economic reasons, as a custom version would have been required.

For this project, this would have been too restrictive. For the customer, the Quintex Overpressure System was the most flexible and efficient.

… the overpressure control by Quintex was the solution with the most flexible options.

The advantages were obvious:

- a high degree of flexibility and design freedom

- easy installation and maintenance

- overall, more cost efficient and technically efficient than other solutions

- therefore, a standard panel by Siemens could be used

Another special feature was to realise the enclosure with a special painting in accordance with customer requirements. Local control functions provide for safe usage and allow for external operation without having to open the enclosure.

At first glance, the Quintex solution may not be different from a conventional control system.

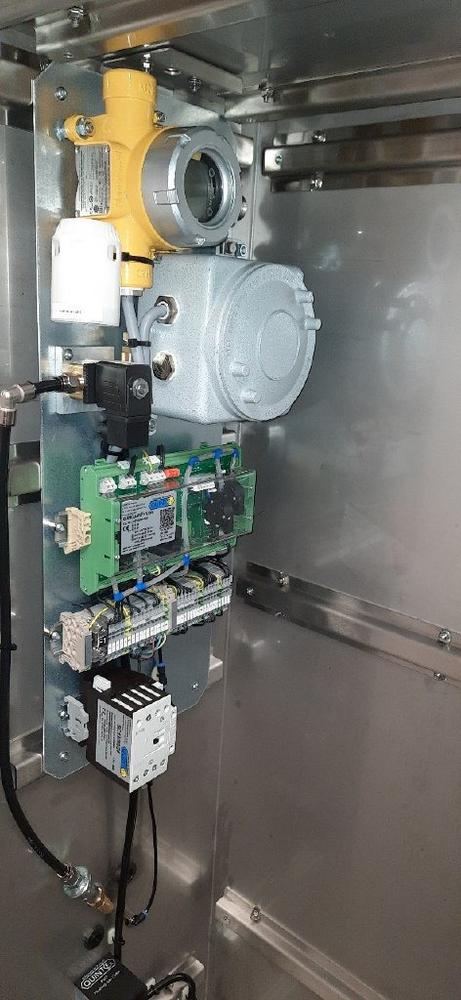

Only experts can make out the difference by spotting the compressed air supply and the Ex type label of the overpressure control for zone 1 potentially explosive areas.

There are no additional components at the exterior of the enclosure.

The Quintex solution:

With the system, by automatic clearance measurement inside the enclosure with an approved, stationary gas detector, the non-existence of an Ex area can be verified and, with the overpressure during operation, a non Ex area can be retained.

Only when no flammable gas is detected in the enclosure and, in addition, the pressure inside the enclosure, as specified in the Ex standard DIN EN 60079-2, is maintained, the following electrical components will be switched on.

… this is fully automatic without the customer having to carry out any operation.

The customer only has to ensure that, for the cabinet, electrical supply and industrial compressed air is available.

… within 2 minutes, the system is ready for operation, irrespective of the size of the enclosure.

With its special solution, Quintex allows for the zone 2 panel to be operated with complete functionality of a touch screen in zone 1.

The touch screen is implemented with a special foil, which is flushed with compressed air.

This design guarantees explosion protection even in case of damage. As high overpressure is not required to flush the enclosure, the foil is not endangered at no time.

To save space, all the components are premounted on plates inside the enclosure by Quintex.

The costumer receives an overpressure-proof cabinet. This allows for the final installation to be carried out within the manufacturing facilities of the customer.

… thus, expensive final inspections can be avoided.

With this system, small enclosures as well as large floor-standing cabinets can be realised.

The implementation is proven by practical experience. It offers a high degree of freedom for self-assembly, without risking the required safety.

… the customer is enabled to assemble the mounting plate, to set up electrical wiring and to install the plate in the cabinet later on.

The mounting plate is delivered with all the required overpressure components, proven in accordance with the Ex criteria, by Quintex.

Specifically with the maintenance of the system and failure-free operation, the Quintex implementation offers obvious advantages and a high degree of customer benefit.

It is an extremely efficient and safe solution when dealing with production down time / interruptions. The system can be easily and rapidly switched on again.

… the system is approved in accordance with ATEX and IECEx.

This solution is tested and certified by two independent certification bodies.

Thus, safe usage is guaranteed in zone 1 and 21 as well as in zone 2 and 22.

Many of the systems sold by Quintex are application-specific solutions, with which the problem and solving the problem for the customer are the main focus.

In principle, however, there is also the option to merely buy the electronic components required for monitoring the non-Ex area by Quintex and to use your own cabinet.

The experts at Quintex give individual advice to each of its customers for finding the optimal solution for their application. In addition, in a concerted effort, the required technical parameters are discussed for a failure-free and safe operation be guaranteed at any time in the potentially explosive atmosphere.

Quintex GmbH manufactures and supplies material for trace heating (heating tapes, heating cables, controller, connection sets) and explosion protection ( Ex e terminal boxes, pressurized systems, line bushings,own range of local control function, local control stations – all can be specified and ordered online)

We manufacture all our material in our own approved (ATEX, ISO, FM, CSA…) facility.

By this we can guarantee our high level of quality, reliability and in time delivery.

Quintex GmbH

i_Park Tauberfranken 13

97922 Lauda-Königshofen

Telefon: +49 (9343) 6130-0

Telefax: +49 (9343) 6130-105

https://www.quintex.eu

Telefon: +49 (9343) 61300

Fax: +49 (9343) 6130105

E-Mail: info@quintex.info

International Sales

Telefon: +49 (9343) 6130-210

Fax: +49 (9343) 6130-105

E-Mail: reiner.friedrich@quintex.info

PM

Telefon: +49 (9343) 6130-221

Fax: +49 (9343) 6130-105

E-Mail: michael.knoegel@quintex.info

International Sales A-B-CH-NL

Telefon: +49 (9343) 6130-218

E-Mail: simon.michelbach@quintex.info

International Sales support

Telefon: +49 (9343) 6130-123

Fax: +49 (9343) 6130-105

E-Mail: Kathrin.Neumann@quintex.info

Deutschland Mitte

Telefon: +49 (151) 46176743

E-Mail: peter.volz@quintex.info

![]()