Testing technology for safe medical products

Quality assurance places the highest demands on testing technology, testing software and documentation. In addition to compliance with standards and regulations, the risks to the patient must also be minimized.

Hegewald & Peschke Meß- und Prüftechnik GmbH has developed suitable testing solutions for the various examinations in the field of medical technology, which are suitable for surgical instruments and protective gloves as well as for testing biomaterials.

Test puncture resistance of protective gloves

The resistance of a protective glove material to degradation by a liquid chemical is determined, for example, by measuring the change in puncture resistance of the glove material after continuous contact of the outer surface with the stressing test chemical. The test applies to gloves made of natural or synthetic polymer and latex materials.

Universal testing machines of the Inspekt duo series are used here, which are equipped with a special testing device for the puncture test. Comparative tests are carried out on glove cut-outs with and without chemical contact. The test fixture consists of a test mandrel for the puncture test according to DIN EN 388, a screw clamp as a holder for the rolled rim bottle, and a rolled rim bottle to hold the specimen.

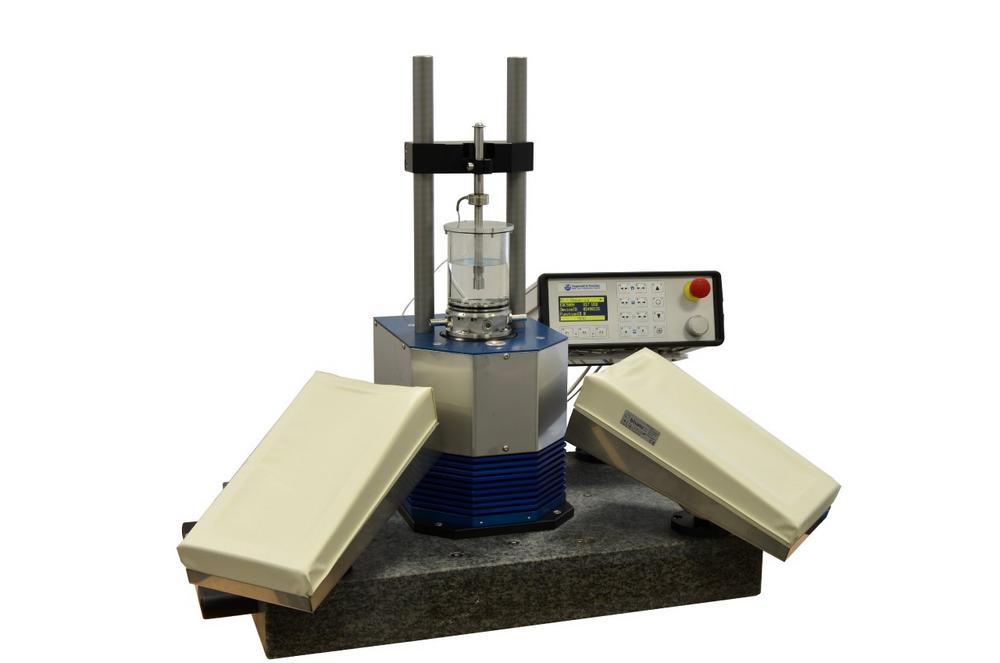

Only very small test forces are required for testing dental implants. A so-called micro testing machine, such as the Inspekt micro LC 100N, is suitable for this purpose. The testing machine can be equipped with a liquid container for wet tests. In this way, tests on dental implants can be carried out under real conditions, as they are in the oral cavity with saliva.

Materials testing software records all test data

The testing machine with a maximum load application of 100 Newtons as well as 50 Hertz for alternating loads can very well simulate continuous loading. Thus, all material fatigue caused by mechanical load and environmental conditions is recorded. The recording and evaluation are carried out with the material testing software Labmaster of the testing technology specialist from Nossen and can be synchronously visualized via a video module.

The product portfolio of the Saxon specialist also includes the testing of surgical instruments, such as component tests for determining the strength of laser welded joints, as well as the testing of implant materials and laboratory instruments. Also possible are squeeze-out tests on syringes to determine the optimal consistency of bone cements as well as suitable cannula diameters.

The measuring and testing technology specialist based in Nossen near Dresden has been developing, producing and selling high-quality machines, components and software solutions for materials, part and component testing since 1990. These include, for example, universal testing machines, hardness testers, component and furniture test stands, and various length measuring devices for industry and research. The company’s 70 employees, with sales offices throughout Germany, also offer various services related to testing and measuring, as well as retrofitting universal testing machines. In the areas of design and software development, Hegewald & Peschke maintains close cooperation with universities and Fraunhofer institutes, ensuring the high standard of its products as well as their technical up-to-dateness. Hegewald & Peschke has been certified according to ISO 9001 and offers calibrations with DAkkS accreditation. For more information about Hegewald & Peschke GmbH, please visit www.hegewald-peschke.de.

Hegewald & Peschke Meß- und Prüftechnik GmbH

Am Gründchen 1

01683 Nossen

Telefon: +49 (35242) 445-0

Telefax: +49 (35242) 445-111

https://www.hegewald-peschke.de

Marketing

Telefon: +49 (35242) 445-607

Fax: +49 (35242) 445111

E-Mail: cornelia.graf-chmiel@hegewald-peschke.de

![]()