Sealing expert expands portfolio of shaft grounding rings

KACO’s modular system of shaft grounding rings, specially developed for the electrification of vehicle drives, ensures electrical connection and thus permanent equipotential bonding without the risk of damaging currents in bearings and gears. It thus avoids bearing and gear damage due to electrical current transfer and prevents noise in the medium frequency range by reliably discharging shaft voltages and currents to electrical masses. In addition to providing elementary protection for machine elements, KACO’s shaft grounding rings also make a significant contribution to EMC shielding in the vehicle.

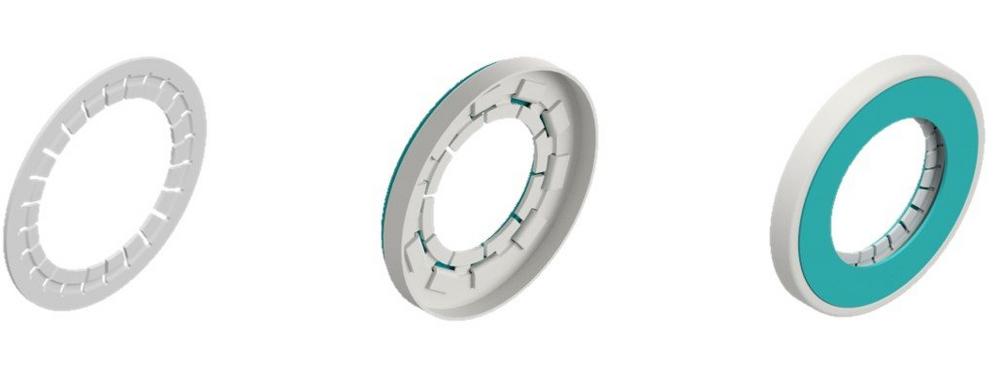

The modular construction kit offers a selection of different options so that each application can be individually solved. The solutions are less expensive because the number of components has been significantly reduced. The modular system available today offers optimum grounding in the form of a single grounding element (NMP), standard designs with metal housings (SMP, DMP) or a customer-specific assembly.

The various versions differ in their composition (depending on customer specifications, application location/type and value-added function). Possible applications are without metal part (NMP*), with one metal part (SMP*) and with two or more metal parts (DMP*). Furthermore, the customer can decide whether the carrier part is to be mounted on the rotor shaft (outer rotation) or in the housing of the electric motor (inner rotation).

Shaft grounding rings from KACO are not only optimized for the specifications of electric drive trains in a dry environment, but can also be used for applications in an oily environment. Applications with circumferential speeds of up to 45 m/s and for ambient temperatures from -40 to 140°C are already in series use. Optimizations and further solutions for higher circumferential speeds and temperatures are being tested, but today’s series production designs are covering almost all current applications to date.

As shown in diagram 1, the electrical impedance in the dry state is well below 5 Ω between the shaft and housing at a running time of over 3,500 hours. A customer-specific speed profile with circumferential speeds of up to 45 m/s is applied. Compared to other solutions, shaft grounding rings from KACO thus offer excellent long-term performance at an extremely low resistance level, which can be implemented very cost-effectively depending on the customer’s installation situation.

The products developed by KACO thus provide effective bearing and gear protection, by significantly reducing the impedance between the shaft and housing over the entire service life. Furthermore, they are independent of the direction of rotation of the rotor shaft and are therefore equally suitable for both forward and reverse drive. Due to its specialization in the development and production of a modular system of grounding rings, KACO is an optimal system and development partner.

Testing under real conditions in specific test field

KACO has worked closely with vehicle manufacturers and system suppliers to demonstrate the performance of its portfolio of shaft grounding rings on special test rigs built for this purpose. Measurement methods and new evaluation algorithms have been developed for the specific requirements of e-mobility. KACO’s testing capabilities for shaft grounding rings include application-specific tests as well as advanced mechanical, chemical and climatic tests. Thanks to targeted investment in specific test rigs for shaft grounding rings, KACO can now evaluate load profiles taking into account very high speeds, minimum and maximum temperatures or runout deviations of the overall system. Based on expert knowledge of materials and friction optimization, radial force and temperature development for contacting over service life can be determined based on the application. KACO is thus the first choice for the development of grounding solutions for e-mobility.

"Solution-oriented material and product development in a specifically established test field were the success factors for the development as well as further development of our modular system for shaft grounding rings. An in-depth analysis of previous approaches to shaft grounding led us systematically to a robust, compact modular product kit that is cost-optimized for the function, so that a permanent current flow between shaft and housing is guaranteed. The different variants as well as material combinations solve the known disadvantages of alternative approaches to shaft grounding. It has proved to be right that we invested the appropriate resources in the development and testing of our shaft grounding rings several years ago. As a result, we can now offer our customers considerable added value as a competent system partner for the development of electric drive trains. Of course, we are continuously improving this young product group, so we are further optimizing the conductivity of our modular system with a focus on best performance over lifetime and wet or oily environmental conditions," explains Vice President Engineering Andreas Genesius.

*NMP: no metal part, SMP: single metal part, DMP: double metal part

The data and values listed here were determined under model and laboratory conditions. They do not represent assured properties, guarantees or warranties. The validation of the products in the respective application, their performance and their suitability for a specific purpose is in the responsibility of the user.

KACO GmbH + Co KG, a subsidiary of the Zhongding Group, is one of the world’s leading developers and manufacturers of high-precision, application-oriented sealing solutions for the automotive and engineering industries. The company, which is based in Germany, is characterized by the highest sealing quality and innovative strength and stands for recognized development and manufacturing expertise. KACO has six plants in Germany, Austria, Hungary, China and the USA and delivers its products all over the world. As a close partner of the automotive industry and its suppliers, the company has been keeping pace with the high demands and technical changes in the industry for decades.

KACO GmbH + Co. KG

Industriestraße 19

74912 Kirchardt

Telefon: +49 (7266) 9130-0

Telefax: +49 (7266) 9130-1386

http://www.kaco.de

Marketing Manager

Telefon: +49 (7266) 91301121

E-Mail: kerstin.adam@kaco.de

![]()