Devastating Water Leak Drives Move to Improve Sustainability

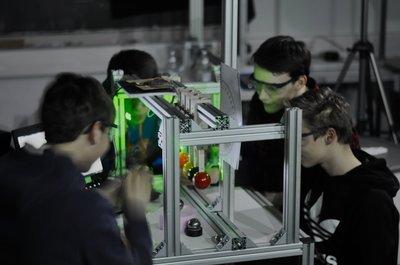

The Maulide Group at the University of Vienna (Austria) describe how a devastating water leak in a nearby chemistry laboratory prompted them to search for alternative, water-free, options to Liebig condensers for refluxing. The group teamed up with Green Labs Austria to see if they could provide and share a more sustainable solution to water cooled refluxing in the lab. Green Labs Austria (https://greenlabsaustria.at/) is a non-profit association, started by students, postdocs and technicians from the Department of Functional and Evolutionary Ecology, at the University of Vienna, to serve as a platform for communication and discussion of sustainability practices within the laboratories. A key aim of Green Labs Austria is to reform how scientists throughout Austria and beyond think about energy and water usage, plastic consumption, recycling and traveling.Professor Nuno Maulide commented "One of our research interests is the development of atom-economical chemical processes. We are convinced that saving resources on a macroscopic scale (water, solvents, consumables) is equally important as on a molecular scale. However, for many years we had been using oil baths and Liebig water condensers for our reflux reactions. It was a devastating, and costly water leak that prompted us to take action and look for ways to minimise water use, and with that the risk of a similar incident occurring again. It also gave us the ideal opportunity to utilise a more sustainable way of working which is very important to us. Dr Daniel Kaiser (Post Doc in the Maulide Group) was able to rethink our lab tools and methods without having a negative impact on our chemistry and worked closely with Logan Hodgskiss (Green Labs) Austria) to share our experience with other labs looking to go green ".Professor Maulide added "Green Labs Austria was enthusiastic about their experience with lab tools from UK-based sustainability specialists – Asynt. As a direct alternative to a water condenser, we have found the CondenSyn air condenser extremely convenient to use and its ‚plug-and-play‘ installation has rendered reaction set up very straightforward. We have also found the CondenSyn air condenser to be very efficient at condensing refluxing solvents – even volatile liquids such as methylene chloride. In addition, swapping out our messy oil baths for DrySyn MULTI oil-free heating plate, not only improved user safety, but has allowed us to run three reactions simultaneously at the desired temperature, requiring minimal space and only one magnetic hotplate stirrer. This also reduces our energy consumption within the lab. With no loss in agitation efficiency, we have found that the DrySyn warms up our reactions much more rapidly than a common oil bath, and the temperature regulation is excellent. This new heating device is more energy efficient and we no longer have to find a way to dispose of degraded or contaminated oil from our oil baths". Dr Kaiser concluded "The fact that we’re saving huge volumes of tap water and not having to dispose of large quantities of waste heating oil allows the Maulide Group to significantly reduce our impact on the environment. We also no longer need to worry about the hassle and potential risks of water use. The ability to set up our experiments to reflux without concern over water flow rates and extra tubing cluttering up the fume hood is great!"The Maulide Group at the University of Vienna are a dynamic and enthusiastic international group of researchers passionate about (organic) chemistry. The Group are taking action on a daily basis to reduce the environmental impact of their labs and are now a member of the Green Labs Austria initiative. For further information please visit https://organicsynthesis.univie.ac.at/. For further information on the CondenSyn air condensers please visit www.asynt.com/products/benchtop-synthesis-tools/condensyn-air-condensers/, the DrySyn MULTI (www.asynt.com/products/benchtop-synthesis-tools/drysyn-range/drysyn-multi-position-blocks/), or contact Asynt on +44-1638-781709 / enquiries@asynt.com. Asynt is a leading supplier of affordable products, consumables and services for chemists in industry and academia. With staff of trained chemists – Asynt can draw upon this in-depth applications knowledge to provide a high level of customer support for its DrySyn Heating Blocks, Controlled Lab Reactors, Synthesis Tools, Evaporators, Circulators, Temperature Control Systems, Vacuum Pumps and Lab Safety Equipment.

Firmenkontakt und Herausgeber der Meldung:

Asynt Ltd

Unit 29, Hall Barn Industrial Estate

CB7 5RJ Cambridgeshire

Telefon: +44 (1638) 781709

Telefax: +44 (1638) 781706

http://www.asynt.com

Ansprechpartner:

Dr. Bill Bradbury

Director

Telefon: +44 (20) 8546-0869

E-Mail: WBPRIMETEK@aol.com

Director

Telefon: +44 (20) 8546-0869

E-Mail: WBPRIMETEK@aol.com

Weiterführende Links

Für die oben stehende Pressemitteilung ist allein der jeweils angegebene Herausgeber (siehe Firmenkontakt oben) verantwortlich. Dieser ist in der Regel auch Urheber des Pressetextes, sowie der angehängten Bild-, Ton-, Video-, Medien- und Informationsmaterialien. Die United News Network GmbH übernimmt keine Haftung für die Korrektheit oder Vollständigkeit der dargestellten Meldung. Auch bei Übertragungsfehlern oder anderen Störungen haftet sie nur im Fall von Vorsatz oder grober Fahrlässigkeit. Die Nutzung von hier archivierten Informationen zur Eigeninformation und redaktionellen Weiterverarbeitung ist in der Regel kostenfrei. Bitte klären Sie vor einer Weiterverwendung urheberrechtliche Fragen mit dem angegebenen Herausgeber. Eine systematische Speicherung dieser Daten sowie die Verwendung auch von Teilen dieses Datenbankwerks sind nur mit schriftlicher Genehmigung durch die United News Network GmbH gestattet.

![]()