Efficient, quick, energy saving – the new cooling method by mycon SplitMaster offers new opportunities

Furthermore, this method can help to increase efficiency when it comes to cooling systems that e.g. employ two ways of circulations.

Whether in the car industry, rail industry, airplane industry, mechanical engineering, electronic engineering or the plastics industry: the adhesion of prefabricated parts is becoming increasingly important.

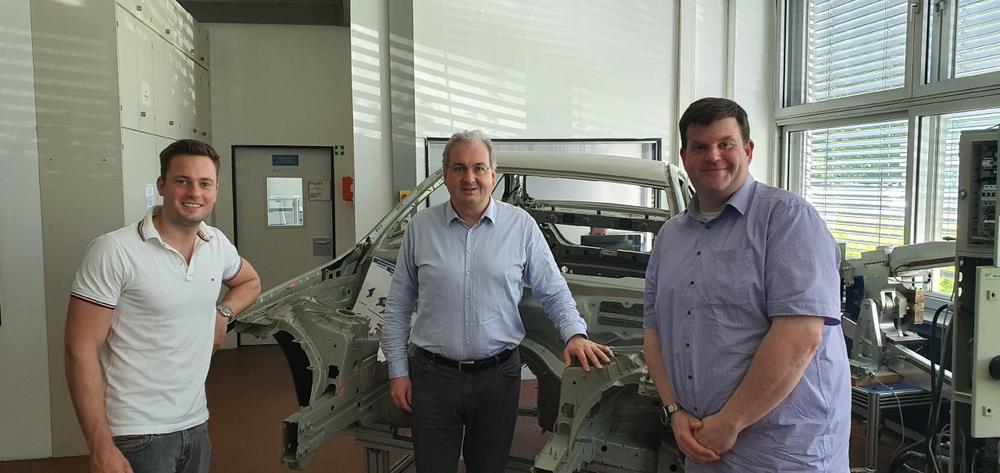

mycon also developed a particular cooling method for this field of application. For a long time, the university of Paderborn as well as the university of Hamm-Lippstadt have made efforts to learn more about the non-destructive dissection of glued parts. This happened in co-operation with several automobile manufacturers and suppliers. Meanwhile, most industrial sectors utilize the adhesion of parts as it provides significant advantages, such as weight saving, distortion-free and extremely stable connections as well as the decrease of postprocessing.

Separating glued parts, however, posed a problem in the past. Although it is possible to dissect adherends by adding immense heat on them, it shows to be a rather effortful process. It would namely be necessary to heat up the surface of the glued parts to 350-400° which can cause severe material damage. Therefore, the university of Paderborn and the university of Hamm-Lippstadt developed an appliance that separates glued parts through partial cooling exposure. Reaching the necessary cold temperatures by usage of easily applicable deep-freezing methods, however, proved to be problematic. Owing to mycon’s new cooling method SplitMaster this problem could be solved. It embrittles and thus dissects glued parts through cooling processes within short periods of time.

The new mycon-method SplitMaster enables non-destructive dissection of glued parts. Thereby, their repairing and recycling become more efficient.

The university of Paderborn and the university of Hamm-Lippstadt will continue researching the dissection of glued parts through cryogenic temperatures. mycon already acquired the respective patent application. mycon is continuing to provide their co-operation partner with the necessary means and equipment to support further research in this field.

About mycon GmbH

mycon GmbH, a sister company of the service company Kipp Umwelttechnik GmbH, develops, manufactures and markets new products and automation technologies.

mycon GmbH currently services customers in approx. 40 countries.

Many years of experience in the field of industrial services led to several system developments and patents, some of which have received international recognition.

mycon GmbH supports customer groups from various industry and service sectors:

Automotive industry

Construction and building renovation industry

Chemical industry

Printing industry

Electrical industry

Waste disposal companies

Foundry industry

Municipal enterprises

Power generation industry

Plastics industry

Paint and coating industry

Food industry

Mechanical engineering

Oil and gas industry

Steel industry

Textile industry

mycon GmbH

Senner Straße 156

33659 Bielefeld

Telefon: +49 (521) 329230 44

Telefax: +49 (521) 402482

http://www.mycon-germany.com

Telefon: +49 (521) 403090

Fax: +49 (521) 402482

E-Mail: marketing@mycon-germany.com

![]()