Success with the BLANK production system: Increased efficiency through process restructuring in the foundry

Approach I: Transparency and communication

Changes and process adjustments do not always have to be rocket science. It often helps to remember the core process as well as the golden rule: communication and openness in dealing with the workforce. What sounds simple at first becomes a real challenge, especially in many medium-sized companies that have grown quickly. This is also the case at the BLANK-Group in Riedlingen. "What used to work in the "small official way" has now become more complex and has an impact on adjacent work processes," says Schäfer. In addition, the plants and kilns extend over different parts of the building, which makes consistent communication and coordination more difficult than in a building structure that was originally designed specifically for one activity. The result: it quickly becomes confusing – a no-go for safe production planning.

Peter Schäfer fought against this state of affairs and achieved a lot within a short time. Using the lean management approach, existing processes were examined and critically scrutinised under the premise of "What can be improved quickly?”. The result: a diverse package of measures that delivers high added value through many small improvements and increases employee motivation.

1. Create transparency

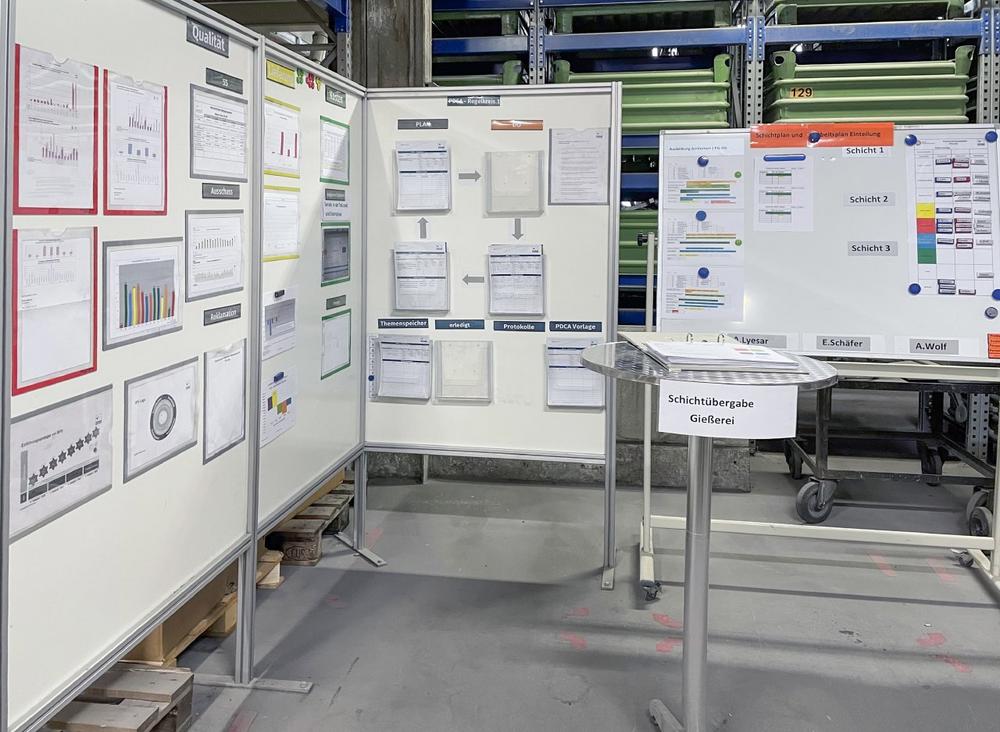

In order to increase transparency within the individual shifts, the workflow was fundamentally reorganised through a structural change. "Across the entire company group so-called group spokespersons were introduced for each shift. They schedule the employees on an assignment board," explains Peter Schäfer. In the case of the foundry, for example, there are the deployment fields "open casting", "roll-over process" or "multi-move robot".

2. Making information easily accessible

Peter Schäfer additionally established information displays in the casting area that provide information about the status of the individual plants. "Especially due to the structures that have grown over the years, it is not obvious at first glance what the total output of a plant is on a daily or shift basis. Here information boards with an integrated abacus help to show the number of castings made," says Schäfer, "An outlook is also possible in this way. The boards not only show the current status, but also what still needs to be done in the course of the week." The graphic representation also enables the group spokespersons to get a quick overview and, if necessary, to react quickly in case of deviations.

3. Improve communication

Open communication is the basis for successful cooperation. In the foundry, however, restrictions arise simply because of the work processes: The entire team of a shift cannot meet for a team meeting because the furnaces must always be occupied. But how is it ensured that the information nevertheless reaches all employees? Through short information paths, regular discussions and the integration of the new information boards this deficit could be eliminated quickly and easily. As a pilot project the department is additionally testing the proof of training via a ticket system. "The employees read the numbered training sheets and then "stamp" on their training card the information they received," explains Schäfer, "We have a quick insight via the cards if there is still a need to catch up. In addition, the topic of personal responsibility is again promoted here, because we rely on the conscientious training declaration of the employees."

Approach II: Clarity and personal responsibility

For the general process flow, in addition to open communication a clear process and the enabling and empowering of employees are decisive for successful cooperation. The second part in the series on process restructuring in the foundry focuses on these important aspects.

4. Clarity

During the investment casting process, wax parts are produced with the help of an aluminium tool, these are assembled to so-called trees and then covered with ceramic mass and sanded. The resulting shells are then first melted out in the foundry before they can be fed into the casting process. The challenge here is that the shells are often similar which makes visual inspection difficult. A reference to the production order is only possible through the enclosed production papers. In this case the clarity could be increased by a colour system. Each melting unit, as for ex. the "roll-over process" or "multi-move robot", is assigned a colour that is reflected on the corresponding trolleys that transport the shells.

5. Increasing the reference to the end product

Another topic close to Peter Schäfer’s heart is the reference to the end product. "At BLANK about 1500 different models of about 400 customers are manufactured every year. As a result, most employees do not know what they are currently working on or in which device a casting will be used later. But I am convinced that the motivation in the team increases when you know what you are working on. In addition, you have to keep reminding yourself that there is a value, a commitment, a task behind every casting – in my opinion, this respect, also towards the complex production process, is a basic prerequisite." Therefore, a showcase has been installed in the casting department displaying investment castings with information on the end application. Additionally a new part and its intended use is presented every month throughout the company. But there is also another intention behind the involvement of the foundrymen. "The employees in the casting area only see the shell and the hot melt. If run-out errors occur during the casting process, they cannot always be explained immediately in many cases," says Schäfer, "This is where the foundrymen can help us, because they are in the middle of the process and often recognize better a pattern with regard to melt, geometry and run-out defects."

6. Promoting personal responsibility

This conviction also played a decisive role in another of Peter Schäfer’s concerns. For him one premise applies to all activities that occur in the casting area: to make the employees more responsible. "We are not all car mechanics. Nevertheless, everyone can check the oil level and change the wheels. I would like to achieve this state in the foundry as well." The employees should be able to react proactively and be well acquainted with their tools, the casting furnaces. Maintenance interventions can thus be prevented or, when they occur, recognised in time and dealt with at little expense.

"As a supervisor it is important to give self-determination and responsibility back to the worker. Only then potentials can unfold and a learning effect occurs. It is deadly when supervisors get bogged down in micromanagement."

Approach III: Cooperation

The third report in the series on process optimisation in the foundry is dedicated to the topic of cooperation. Beside many hard facts especially the soft facts contribute to employee motivation and productive cooperation. Therefore this aspect was also critically examined within the scope of the improvement processes in the foundry sector.

7. Working together

The cohesion of a department plays a decisive role for a smooth workflow. Within the shifts a sense of "we" quickly develops through daily cooperation. People help each other. It becomes more difficult with cross-shift activities: "In the foundry, for example, materials have to be prepared for the next shift or the furnaces have to be prepared accordingly. In the past there were always points of friction here. Each shift worked for itself, which often delayed the activities in the next shift," explains Peter Schäfer, "We were able to achieve a lot here through targeted discussions and new work processes. Preparing for the next shift is now a regular part of the workflow."

But cohesion is not only important within departments. Upstream and downstream processes must be also integrated. "There was often too much isolated thinking. Today, employees help each other out, move between departments and thus grow further together.”

This is right and important in order to survive in the sector of medium-sized businesses in the long term. Markets are volatile and to be able to react to them companies need to be flexible.

Many of the presented approaches aim to create a sense of community among employees. "When you help each other, everyone benefits from easier and faster processes at the end. This had to be learnt again in the department."

The changes led to a sustainable improvement of the working atmosphere. "The feedback so far has been consistently positive. People are having more fun at work," says Peter Schäfer happily. This is also reflected in an improvement in the key figures: The measures have led to a more stable and predictable output. "My conclusion of the past months is that automation, Industry 4.0 and optimisations in production are indispensable for keeping up with the times. However, it is just as important to pick up the employees and bring them along – and not simply present them with a fait accompli. Structuring before automation is the right approach here.”

Texmo Blank Germany GmbH

Industriestr. 18

88499 Riedlingen

Telefon: +49 (7371) 1820

http://www.TexmoBlank.com

Marketing

Telefon: +49 (7371) 182-200

Fax: +49 (7371) 18244-200

E-Mail: manuela.schmid@feinguss-blank.de

![]()