Edelstahl: Die bevorzugte Option für Getriebemotoren in Nahrungsmittel- und Getränkeanwendungen

Yasar Yüce, Product Manager at Bauer Gear Motor, a leading brand of Altra Industrial Motion Corporation, explains why stainless steel is often seen as the best option, but also asks whether this is always the case for end users.

The challenges for engines in the food and beverage industry are diverse. Strict hygiene standards apply to all equipment in production plants. Wet cleaning with high pressure water jets and chemicals take place regularly, so any equipment that is operated under these conditions must offer a high level of penetration protection in order to protect the internal parts from damage. A high IP protection class is essential.

Wet cleaning is used to limit the spread of contaminants. In order to limit this spread further, components such as gear motors should have a smooth design so that impurities and germs cannot adhere to them as far as possible. The smooth surface must also be retained over the long service life, as geared motors are expected to work according to the same hygiene standards for many years without endangering the quality of the food or beverages produced in the system. Corrosion carries the same risks, which is why a very resistant exterior is a minimum requirement for every geared motor.

The hygiene standards are prescribed by federal and state laws, so that all coatings or materials that are used in a design must comply with these regulations that are already in force. Organizations such as B. the FDA and the NSF ensure compliance with these standards in the USA.

Stainless steel gearmotors are often chosen because they can meet all application requirements without the need for additional coatings. As a base material, stainless steel is corrosion and chemical resistant and ensures that repeated wet cleaning does not impair the reliability or FDA conformity of the geared motor.

A stainless steel solution is easier to handle than a gear motor, which relies on a special coating to comply with hygiene regulations. Scratches in stainless steel do not affect the corrosion or contamination resistance of the geared motor, so its FDA compliance is maintained. However, if the top layer of the surface coating is damaged, this presents the possibility of contamination. Many anti-corrosion properties are lost in the process. This vulnerability is less than ideal in areas with mechanical risks, where the geared motors may be exposed to shock damage or high maintenance intervals.

On-site maintenance technicians must be aware that any loss of compliance of a gearmotor while correcting the problem will result in lost production. In an industry that operates with small profit margins per unit, protecting downtime is essential to ensuring profitability. With lower maintenance requirements and increased service life that lead to long-lasting FDA compliance, stainless steel gearmotors remain the industry standard.

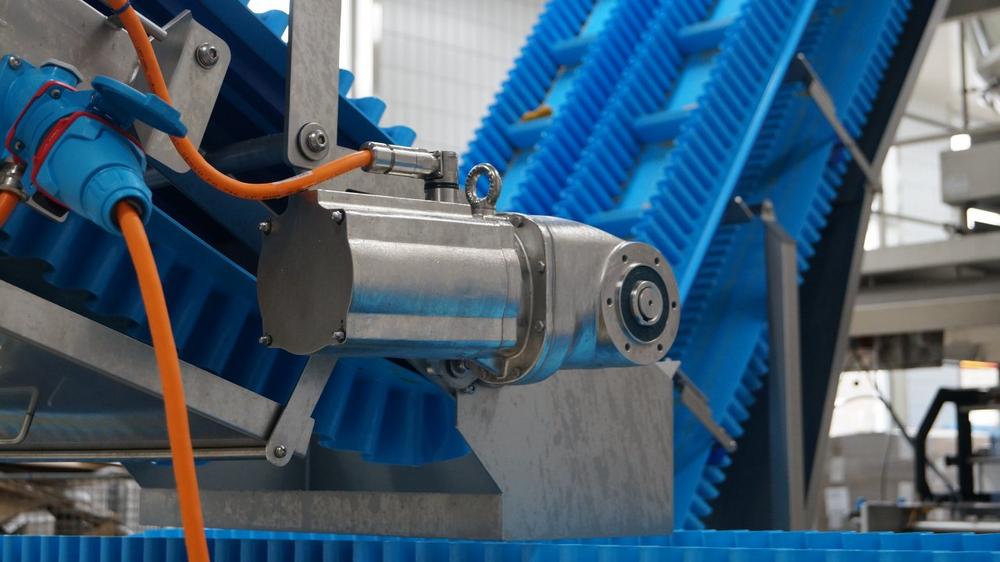

A good example of these coordinated advantages is the HiflexDRIVE geared motor program from Bauer in stainless steel, which is characterized by its compact design, modular integration, energy efficiency and a smooth outer housing that is easy to clean. The advantages are easier installation, lower operating costs and higher productivity thanks to wet cleaning that can be carried out more quickly – all important properties for the system operator.

The HiflexDRIVE was developed for all areas of conveyor technology and is equipped with permanent magnet synchronous motor (PMSM) technology, which offers considerable energy savings under load and enables the geared motor to keep the speed constant even in the event of overload or in the event of a voltage drop – ideal for conveyor applications.

The HiflexDRIVE is specially designed for the requirements of the food and beverage industry. The smooth stainless steel housing does not need a fan or cooling fins and in this way prevents the creation of dirt pockets and re-infections of the surrounding area through turbulence in the room air by a cooling fan. The high mechanical strength of the stainless steel housing also ensures that the hygienic properties are maintained over the long term.

The HiflexDRIVE is available with a high degree of protection up to IP69K and is therefore suitable for wet cleaning in which hot water and high pressure are used. The gear oil and shaft seals are also specially designed for use under these conditions. This and the water-repellent stainless steel housing ensure that the cleaning agents and disinfectants widely used in the industry cannot affect the performance of the engine.

The HiflexDRIVE is available in the efficiency classes IE1 to IE5 and offers inherent scalability of the gear torques in the range from 80 to 330 Nm, which are required for most applications in the food and beverage industry.

The nice thing about mechanical engineering is that every application is different. So that doesn’t mean that stainless steel is the optimal solution for every food and beverage production area. In areas where there is no risk of impact, special hygienic coatings can offer an alternative option for plant operators. Bauer Gear Motor is aware of this and offers a range of aseptic geared motors with optimized coating systems that are resistant to almost all common industrial cleaning agents in the pH range from 2 to 12 – including an IE4 Super-Premium Efficiency permanent magnet motor solution.

Our engineers help customers assess their application environments and provide expert advice on which solution is best. In cooperation with the customer, we can then specify and install an optimal gear motor solution that extends the operating time. In our experience, it is true that stainless steel has become the industry standard solution in the food and beverage industry – but it is important that we offer our customers the most suitable solution for their needs.

Seit über einem dreiviertel Jahrhundert lösen wir Antriebsprobleme überall da, wo elektrische Antriebe mit hohen Drehmomenten für Anlagen, Maschinen und Apparate gebraucht werden. Dank unserer weltweiten Niederlassungen haben Sie unser Angebot auf der ganzen Welt immer in Ihrer Nähe.

Bauer Gear Motor GmbH

Eberhard Bauer Straße 37

73734 Esslingen

Telefon: +49 (711) 3518-0

Telefax: +49 (711) 3518-381

http://www.bauergears.com

Marketing Manager

Telefon: +49 (711) 3518-276

E-Mail: info@bauergears.com

![]()