Robust and Resistant to Cleaning: When Stainless Steel 316L Meets Optical Sensor Performance

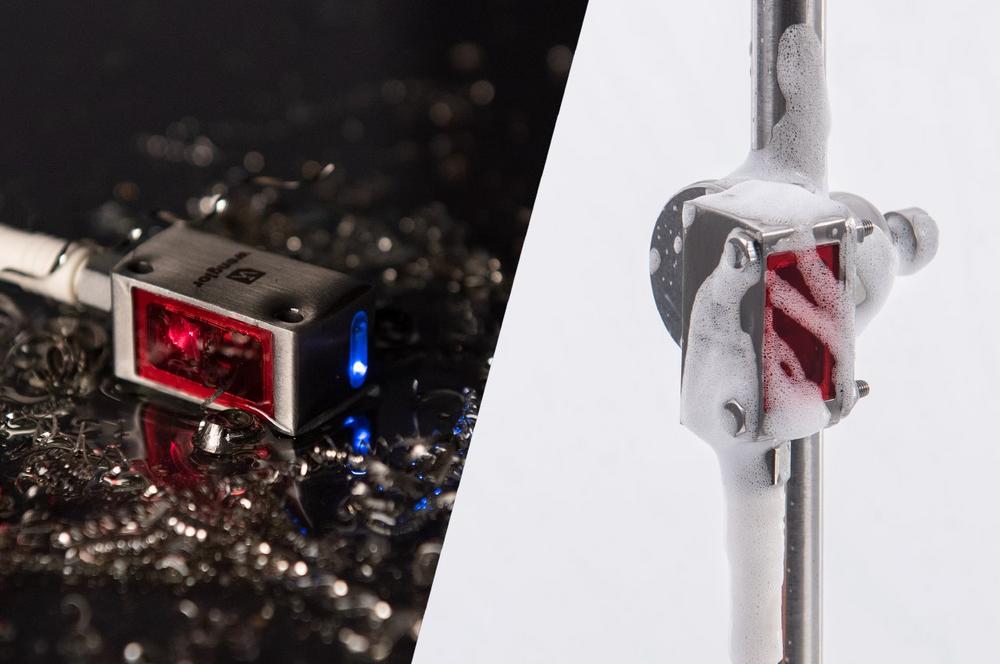

In the food and packaging industries, production facilities must be regularly cleaned with high pressure and aggressive cleaning agents. The high requirements in washdown areas also apply to the sensors installed in the systems. The new 2K series with stainless steel 316L housing (1.4404/V4A) meets these requirements thanks to its high IP69K protection class and ECOLAB certificate. “Splash water, high pressures up to 100 bar and 80 °C water temperature or aggressive cleaning agents do not influence the 2K sensors,” says wenglor Product Manager Christoph Lang. Mounted in a compact miniature housing (35.5 × 18.5 × 17 mm), the photoelectronic sensors are also suitable for applications in mechanical and plant engineering, e.g. in milling machines. Thanks to their robust design, the sensors are also resistant to coolants and lubricants. “The robust sensors are not affected by impacts, knocks, corrosion or other mechanical influences,” Lang continues. “Making them ideal for tasks in heavy-duty industries.”

Robust on the Outside, Intelligent Inside

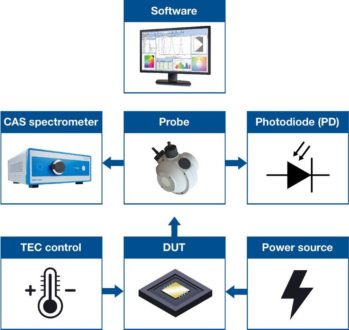

However, 2K sensors not only offer great resistance, but also impress with their well-known PNG//smart properties: A calibrated switching point and an aligned optical axis ensure precise photoelectronic performance and easy integration, adjustment and commissioning. Thanks to the laser class 1, which is harmless to the human eye, the small sensors are also suitable for moving system parts such as robot arms. The integrated IO-Link interface also enables intelligent communication and configuration at the push of a button. “Condition monitoring and data storage make maintenance easier, and batch size 1 production is easy to implement,” continues Lang. “The combination of impressive photoelectronic performance, smart communication and robustness make the 2K series a strong product for any industry.”

The Right Sensor for Every Application

The small 2K design is available for six functional principles: Energetic reflex sensors and reflex sensors with background suppression, universal retro-reflex sensors, retro-reflex sensors for transparent objects, through-beam sensors and long-range laser distance sensors are all now available in stainless steel 316L. A total of three light sources are available: red light, blue light and laser light. With these comprehensive combination options, the right sensor can be selected for any application. “Whatever the industrial environment, whatever the object color and surface condition: The 2K sensors are suitable for contactless object detection for any task.”

The Highlights at a Glance

• Robust stainless steel 316L housing (1.4404/V4A)

• 2K miniature design 35.5 × 18.5 × 17 mm

• IP69K degree of protection

• ECOLAB-certified

• Resistant to high-pressure cleaning up to 100 bar and 80 °C water temperature

• Captive laser labeling for permanent visibility

• Aligned optical axis and calibrated switching point

• IO-Link 1.1 (condition monitoring)

• With potentiometer or teach-in

• Completely visible LEDs

• Flexible mounting through elongated hole

wenglor develops innovative automation technologies, such as sensors, security and 2D/3D camera systems with state-of-the-art communication standards for the global market. Founded as a two-man business in 1983, the family company has since evolved into one of the most important international sensor suppliers with more than 950 employees around the world. The company with headquarters on Lake Constance in Tettnang, Germany, meets industrial automation challenges for customers in all industry sectors – from automotive manufacturing to the packaging industry. More than 60,000 customers from 45 countries all over the world are already placing their faith in wenglor’s innovative products.

wenglor sensoric group

wenglor Straße 3

88069 Tettnang

Telefon: +49 07542 5399 0

Telefax: +49 07542 5399 988

http://www.wenglor.com

Pressereferent

Telefon: +49 (7542) 5399-718

E-Mail: fabian.repetz@wenglor.com

![]()