SMS to supply one of the world’s largest horizontal continuous casters for brass billets to Hailiang Metal Europe

- One of the largest horizontal continuous casters for copper alloys worldwide

- Annual production capacity of up to 150,000 tons

- Consistent product quality thanks to high level of automation

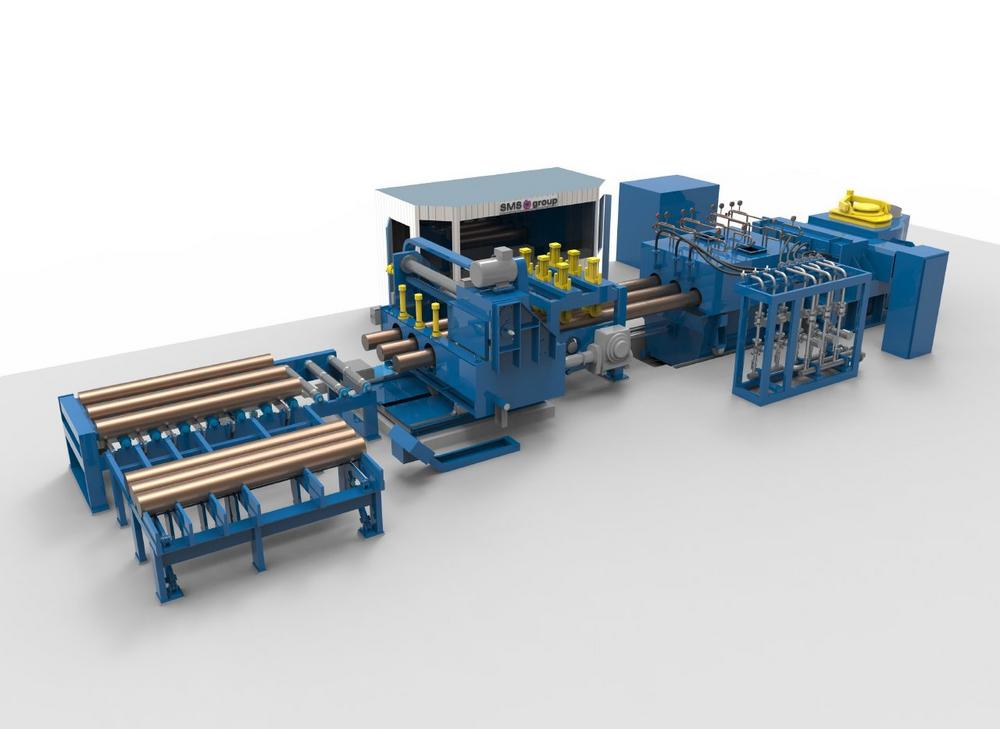

HME (Hailiang Metal Europe) has placed an order with SMS group (www.sms-group.com) for a four-strand, fully continuous horizontal caster for brass billets. The new caster, one of the largest in the world for copper alloys, will replace an existing vertical semi-continuous caster at the company’s Serravalle location in Italy. With this new installation, the Italian manufacturer of brass profiles intends to achieve consistent product quality and boost its productivity significantly.

The new four-strand caster produces brass extrusion billets with a diameter of 245 to 400 millimeters for the subsequent production of profiles using the extrusion method.

"Our overall plant engineering package, consisting of automation through to digitalization, was what convinced HME. HME can fully rely on the reliability, durability, and high design quality of our machines," says Dr. Thomas Winterfeldt, Executive Vice President Forging Plants.

The scope of supply includes a pressure-controlled casting furnace with a capacity of approx. 35 tons, high-performance molds for efficient strand solidification, the withdrawal device with the highly advanced Softcast drawing cycle, a flying saw, the exit roller table with separating device, an automatic cooling water control system for constant process conditions, and the hydraulic unit.

The basic digitalization package consisting of SMS-Metrics (process data acquisition) and Smart Alarm (plant fault monitoring) will assist the operators to increase process transparency, plant availability and, furthermore, it helps to reduce maintenance costs to a minimum. Smart Alarm offers an enhanced overview and better control of error messages and simplifies the process of analyzing system notifications. For greater process transparency, the process and plant parameters can be visualized and evaluated using SMS-Metrics.

The new continuous caster is scheduled to go on stream in the second half of 2022.

SMS group is renowned worldwide for its future-oriented technologies and outstanding service for the metals industry. The company applies its 150 years of experience and its digital know-how to provide the industry continuously with innovative products and processes – even beyond its core business – and generates worldwide sales of more than 2.7 billion euros. SMS is the right partner for challenging projects, and supports its customers throughout the lifecycle of their plants, enabling profitable and resource-efficient value creation chains. Paving the way for a carbon-neutral and sustainable metals industry is the company’s stated goal. As a global player with German roots, SMS takes responsibility for its about 14,000 employees.

SMS group GmbH

Eduard-Schloemann-Straße 4

40237 Düsseldorf

Telefon: +49 (211) 881-0

Telefax: +49 (211) 881-4902

http://www.sms-group.com

Corporate Communications

Telefon: +49 (211) 881-4449

Fax: +49 (211) 881-774449

E-Mail: thilo.sagermann@sms-group.com

![]()