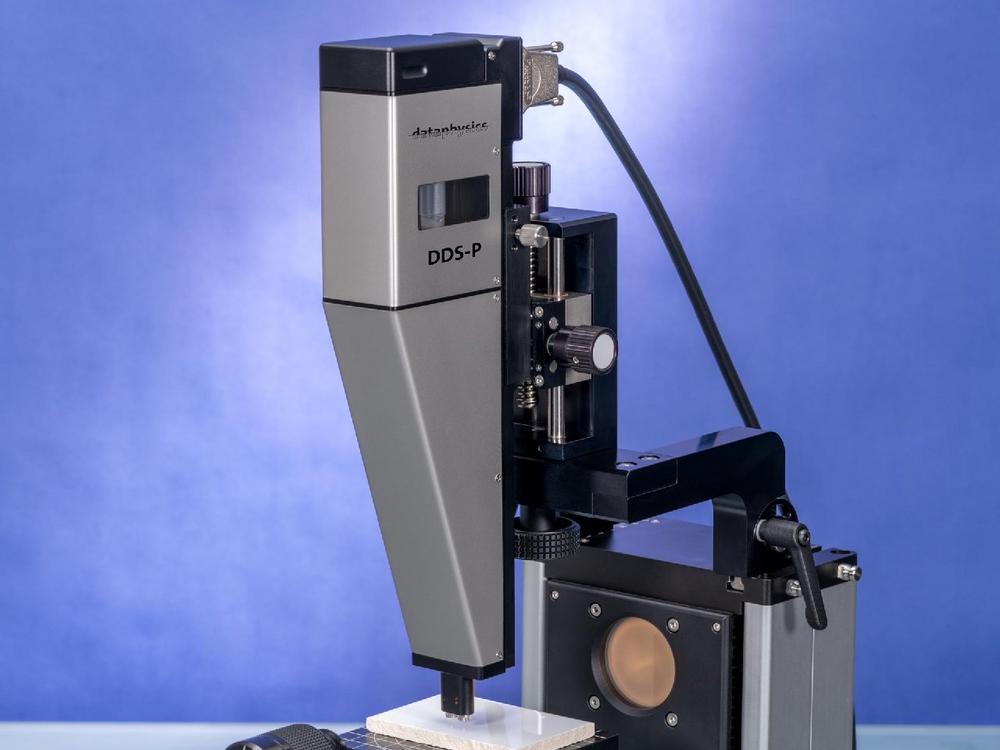

Determine surface energy of solids in seconds with new double dosing system DDS-P

Surface energy is an important parameter when characterising solid surfaces, which allows conclusions regarding the surfaces’ adhesion and wetting behaviour. Therefore, surface energy is important in many fields, such as the development and production of paints and varnishes, adhesives as well as surface treatments.

To characterise the surface energy of solids experimentally, contact angle measurements are needed. To do so, drops of at least two test liquids with known characteristics must be dosed onto the surface of the solid. The newly developed pressure-based double dosing system DDS-P by DataPhysics Instruments makes these measurements significantly easier and faster. Dr. Sebastian Schaubach, Innovation Manager at DataPhysics Instruments, says: "The straightforward handling of the DDS-P is very impressive. Its simplicity facilitates novices‘ first steps using the device and allows more advanced operators smooth and efficient measuring procedures." The double dosing system DDS-P can be combined with many contact angle meters of the OCA-series from DataPhysics Instruments.

Determine surface energy in seconds

As soon as the DDS-P is mounted onto the contact angle meter, the operator can begin the measurement. They place the solid sample onto the sample table and adjust the distance between table and the valves of the dosing system. The settings for the distance can be saved and reused as long as the geometry of the samples remains the same. Using the new device software dpiMAX, one click on the measurement-button for surface energy determination is enough to initiate the entire measuring and analysis process. Aided by pressure, the DDS-P doses drops of two test liquids, like diiodomethane and water, onto the sample. The software then measures the contact angle of both drops and immediately calculates the surface energy of the solid with its polar and dispersive parts. The calculation of the surface energy is based on the model developed by Owens, Wendt, Rabel and Kaelble, also known as OWRK-model.

With the DDS-P, the entire process of measuring and calculating the surface energy only takes seconds. Schaubach says: "The perfect interplay between the software dpiMAX with its modern, intuitive user interface and the newly developed double dosing system DDS-P allows for highly accurate measurements in remarkably short time."

Further time savings are realised as the test liquids in the DDS-P last for many measurements. The drops dispensed by the DDS-P are only about one microlitre small. This means that the three-millilitre-cartridges within the DDS-P hold enough liquid to conduct 3000 measurements before they need to be refilled. "Changing the cartridges is as easy as changing the ink cartridge of a fountain pen," compares Schaubach.

Automatised measurement steps reduce error sources

As the DDS-P doses the liquids drops automatically, operator errors when applying the drops to the sample surface are a now things of the past. With just one click, the DDS-P doses the two drops needed simultaneously. Thus, manual operating steps are reduced to a minimum and the risk for user-dependent errors and inaccuracies is lessened. Together with an automatised contact angle meter like the OCA 50, it is moreover possible to position the sample electronically, without any operator intervention, which minimises the risk for user-dependent errors during measurement even further.

Built for applications with high sample throughput rates

The double dosing system DDS-P is well suited for applications where many samples need to be characterised in a short time frame. This is often the case in quality assurance as well as in many research and development departments. However, regardless of the time constraints, those departments need to ensure both high throughput rates and user-independent, high-quality measurements. In such environments automatised surface energy measurements with the dosing system DDS-P and the dpiMAX-software can realise their full potential. Operators can use the system, for example, to evaluate the effectiveness of surface treatments or to assess variations in quality in the production line. Repeated measurements of the same sample at different positions also allow to judge the homogeneity of the surface.

Existing customers can upgrade many of their contact angle meters of the OCA-series with the DDS-P. New customers can purchase the DDS-P together with a contact angle meter of the OCA-series from DataPhysics Instruments to match their specific application. For more information, please visit our website www.dataphysics-instruments.com/DDS-P or contact us via email info@dataphysics-instruments.com.

If you reprint this press release, we would appreciate a copy.

DataPhysics Instruments GmbH, a German company with 25 years of experience, specialises in measurement technology for surface science. We offer a range of devices, which can analyse chemical and physical properties of surfaces and interfaces, such as their interfacial tension, surface energy, work of adhesion, static and dynamic contact angles, roughness profiles, zeta potential and dispersion stability. In short, our products help determining material properties whenever a liquid meets another liquid or a solid surface. In addition to contact angle meters, our portfolio encompasses spinning drop and force tensiometers, dispersion stability analysis systems, surface profile analysers and zeta potential analysers. Services also include high-quality contract measurements.

DataPhysics Instruments GmbH

Raiffeisenstrasse 34

70794 Filderstadt

Telefon: +49 (711) 770556-0

Telefax: +49 (711) 770556-99

https://www.dataphysics-instruments.com

Marketing Managerin

Telefon: 071177055659

E-Mail: s.doettling@dataphysics-instruments.com

![]()