New multilayer coating system for wafers up to 300 mm dia. by magnetron sputtering

In the volume production of semiconductor components, besides many quality requirements, the yield of usable elements is a crucial factor when selecting the equipment. One way to improve the yield is to use 300 mm wafers (12 inch) instead of the long common 200 mm (8 inch) wafers, since less edge area is unusable here.

This fact has been taken into account by the German thin film equipment manufacturer scia Systems, which is launching a new magnetron sputtering system for 300 mm wafers, the scia Multi 300.

The system was especially designed for the deposition of high-quality multilayers on wafers up to 300 mm. Up to four magnetron sputter targets allow coating with different materials without interrupting the vacuum, which significantly speeds up the production time for a substrate. In order to guarantee the excellent uniformity and reproducibility of each individual layer stack, scia Systems has developed a process configuration with combined orbital and spin rotation for the wafer within the process chamber, while the face-down orientation of the wafer ensures minimal particle load.

The scia Multi 300 is designed for deposition of metal layers as well as oxide and nitride layers. The cassette load lock with automatic substrate handling and the in-house developed control software enables a completely automatic and recipe-controlled process.

Already convinced: Helmholtz-Zentrum Dresden-Rossendorf (HZDR), Germany

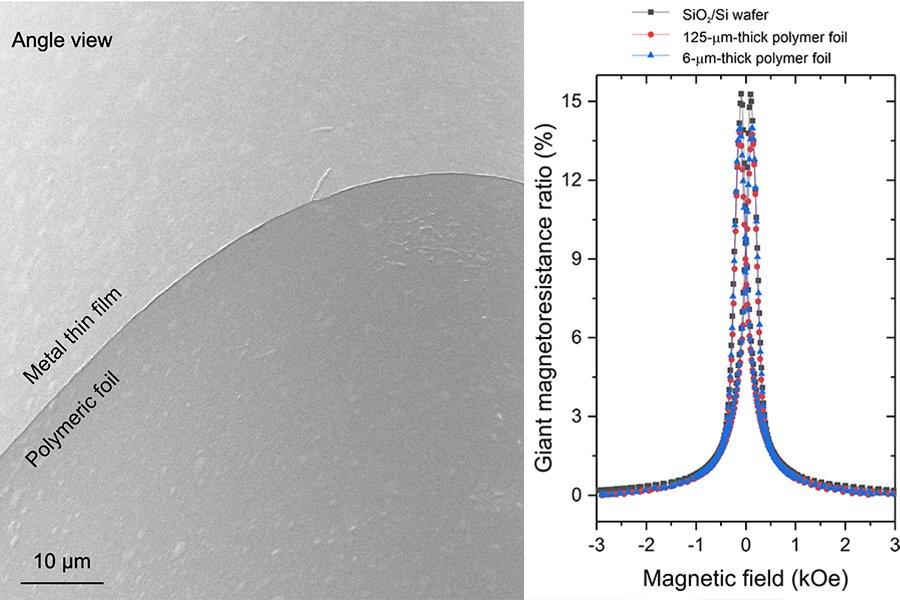

The scia Multi 300 is already being used at the HZDR by the Department of Intelligent Materials and Systems, headed by Dr. Denys Makarov. Main activity of this group is the development and production of flexible and printable magnetoelectronics.

These shapeable magnetic field sensors can be used to measure, control and monitor all kinds of electrical machines, like in consumer electronics as control sensors, in the Internet of Things (IOT) and in smart implants and to control robots or smart home applications. These activities are in the heart of the Helmholtz Innovation Lab FlexiSens.

For the production of these sensors, it is important that the non-magnetic and ferromagnetic layer stacks have a very high film thickness uniformity all the way to the substrate edge and that the process has a very good reproducibility.

scia Systems is pleased to have supplied the HZDR with the scia Multi 300, a suitable system for their tough requirements and their exciting field of research.

Besides that, the system is also suitable for optics processing, e.g., gradient multilayer deposition for anti-reflective coatings and even for EUV (Extreme ultraviolet)-applications. More information about the scia Multi 300 and other suitable applications of this system can be found here: https://www.sciasystems.com/products/magnetron-sputtering/scia-multi-300.html

scia Systems GmbH is a supplier of advanced plasma and ion beam technologies for ultra-precision surface processing. The company develops equipment for the MEMS and microelectronics industry as well as for precision optics manufacturing.

scia Systems is the world market leader of ion beam trimming technology. The best-known system, the scia Trim 200, is used worldwide for the production of high frequency filters in mobile communication.

With headquarters in Chemnitz, Germany, the company operates through partners in Europe, North America and Asia-Pacific. For more information about scia Systems, please visit www.sciasystems.com

scia Systems GmbH

Clemens-Winkler-Str. 6c

09116 Chemnitz

Telefon: +49 (371) 33561-0

Telefax: +49 (371) 33561-200

http://www.scia-systems.com

Marketing

Telefon: 037133561-0

E-Mail: c.kendzia@scia-systems.com

![]()