The new Traction Inverter with Gallium Nitride Chip Technology proves to be a success

Gallium Nitride semiconductors are key to efficiency improvements, increasing the driving range of electrified vehicles. hofer powertrain and VisIC Technologies Ltd. aim to develop Gallium Nitride-based power inverters for electric vehicles, achieving the breakthrough of Gallium Nitride technology for 800V battery systems in the automotive industry.

“We are proud to have achieved the next step in developing efficient GaN-based, high-frequency inverters for 800V automotive applications,” says Lukasz Roslaniec, Electronics Expert at hofer powertrain.

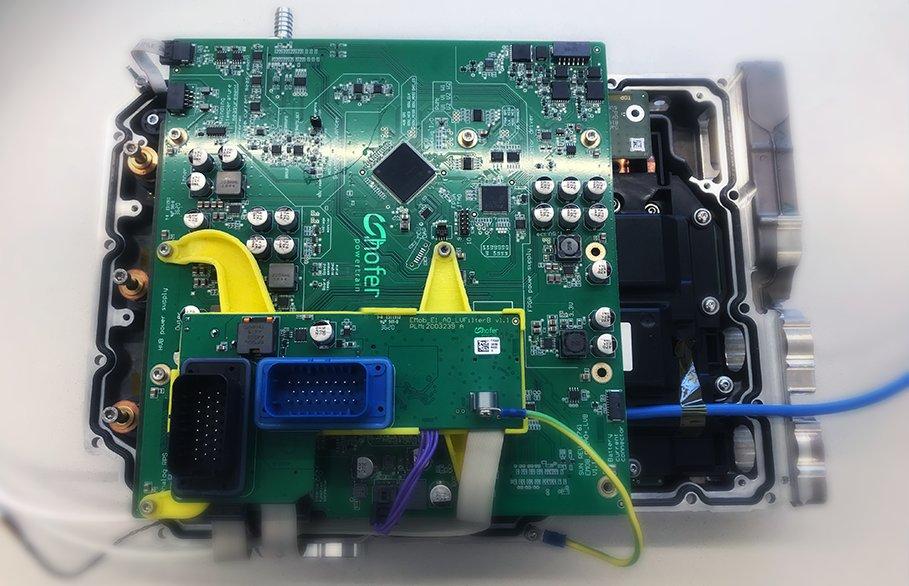

Based on the guiding principle "develop fast and learn fast," hofer powertrain achieves quick results: the team develops a Minimal Viable Product (MVP) to investigate and prove the capability of using 650 V Gallium Nitride semiconductors in an 800 V 3L NPC inverter application: their behavior in terms of switching speed, EMC, and the limits. The main goal is to prove the capability to feed a sinusoidal current of 100 Arms through an inductive load and to perform a double pulse test. Measurements have shown the possibilities of an excellent performance increase.

“hofer powertrain’s development paves the way for a breakthrough in GaN inverter performance, which is superior to silicon and silicon-carbide-based designs for high efficiency,” says Ilia Bunin, Senior Product Manager & Technical Expert at VisIC Technologies.

This system provides valuable insights and in-depth understanding of the short circuit protection, switching properties of the implemented GaN transistors, the impact on dv/dt, oscillations during switching, voltage overshoots, and much more. In addition, the company identifies the most important electrical and thermal properties for rapid further development.

The in-depth understanding was derived from successful customer projects, which act as a benchmark, comparing the individual benefits with an existing 2L inverter, not only at the sub-assembly level but also at the system level.

The upcoming sample stage has already started and is expected to perform well in a series of tests in real-world conditions with a permanent synchronous motor. The team aims to validate and benchmark existing systems using test cycles like the Worldwide Harmonized Light Vehicles Test Procedure (WLTP) and prove its outstanding potential for the entire automotive powertrain.

hofer powertrain is a system supplier, engineering, and technology partner for efficient powertrain solutions covering all classes of electrified vehicles. The company’s primary goal is to increase the efficiency of e-mobility with future-oriented solutions. This goal is achieved through unique, in-depth knowledge of the complete powertrain system, including software, functions, and vehicle integration from pre-development to SOP and beyond. This holistic powertrain expertise is represented worldwide by expert teams in Europe, Asia, and the United States.

hofer powertrain

Ohmstr. 15

72622 Nürtingen

Telefon: +49 (7022) 217884-0

Telefax: +49 (7022) 217884-129

http://www.hofer.de

Communication Specialist / PR

Telefon: +49 (176) 32647902

E-Mail: christina.karuna@hofer.de

Technical Expert

E-Mail: steffen.hahlbeck@hofer.de

![]()