EPUSELF – Do-It-Yourself Mineral Casting from RAMPF Machine Systems

From vibration-damping machine components for customized production technology, low-vibration loud-speaker boxes, to weather-resistant art works – institutes, professional and hobby machine builders, artists, and DIY enthusiasts across the globe are manufacturing high-performance products using EPUSELF mineral casting – easily, quickly, and independently.

- Ready-to-use delivery in 25 kg containers consisting of mineral filling materials, resin, and hardener.

- Easy mixing in provided bucket using slow-running stirrer.

- Direct filling of sheet metal assemblies or casting in molds/simple shells.

EPUSELF exhibits a high damping capacity and very good mass/rigidity ratio. The components manufactured with this innovative casting material are characterized by outstanding thermal stability and high media resistance. In addition to casting or filling vibration-damping machine components such as beds, stands, and portals, EPUSELF is suitable for further applications in acoustics, design, construction, and art.

EPUSELF materials can be processed safely and recycled as construction waste due to their environmental-friendly composition.

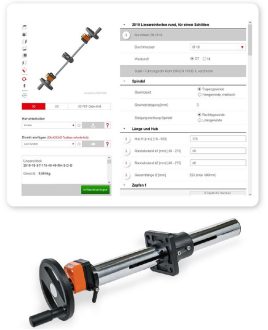

Easier and faster – the RAMPF Web Shop

EPUSELF mineral casting can now be ordered online.

Customers select the mineral casting mixture best suitable for their application and order it using an online template. They then receive their individual offer, including transportation costs.

Dr. Thomas Abel, Director of Laboratory at RAMPF Machine Systems – "EPUSELF enables creative minds to implement their ideas easily and with the highest quality standard. Our dedicated RAMPF design engineers support our customers in developing a design and process suitable for casting, also the using latest 3D CAD technology.”

RAMPF Machine Systems based in Wangen (near Göppingen), Germany, is the market-leading development partner and system supplier of complete machine bed solutions and machine systems.

Its service portfolio includes system solutions, trunk machines, basic machinery, and multi-axis positioning and moving systems based on machine beds and machine bed components made from alternative materials such as mineral casting, hard stone, and ultra-high performance concrete.

High-precision machine systems are produced using innovative replication, grinding, and lapping processes in temperature-controlled production environments.

This makes RAMPF Machine Systems the full-service partner for developing and manufacturing future-oriented machinery and production technology for a huge range of industries.

RAMPF Holding GmbH & Co. KG

Albstraße 37

72661 Grafenberg

Telefon: +49 (7123) 9342-0

http://www.rampf-group.com

Pressereferent

Telefon: +49 (7123) 9342-0

E-Mail: pr@rampf-group.com

![]()