Improved silicon wafer processing for ESA’s X-ray observatory “Athena”

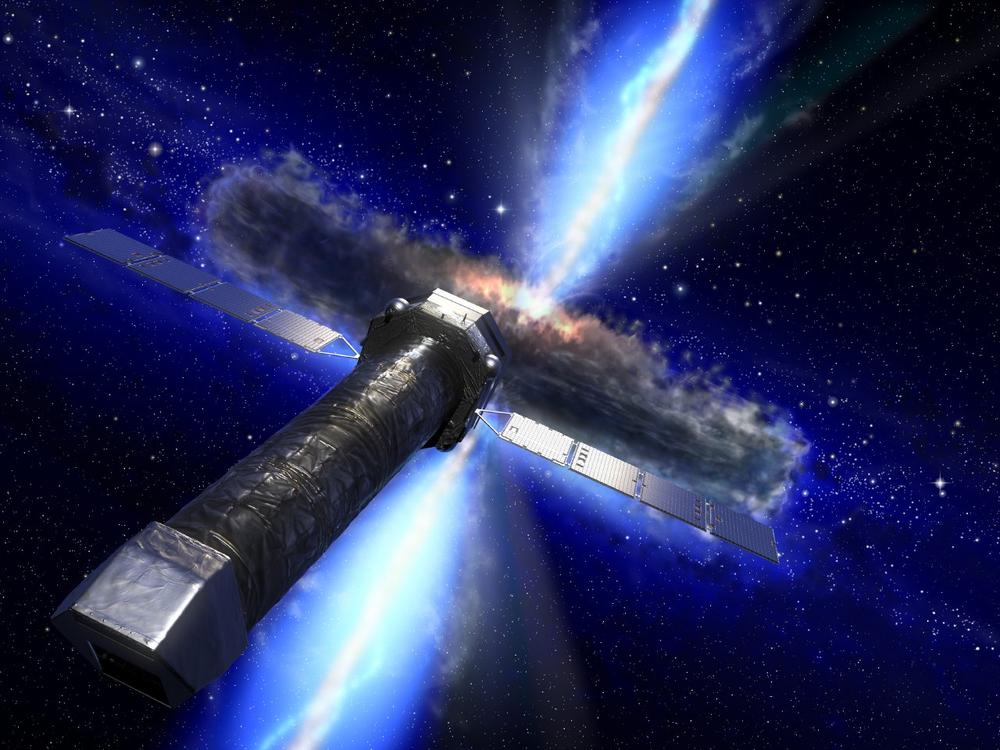

One of the current most important missions of the European Space Agency (ESA) is the largest space-based X-ray telescope ever built: Athena, the Advanced Telescope for High-ENergy Astrophysics. This mission is the second ‘Large’ mission (L2) in the ESA Cosmic Vision programme with the theme of the “Hot and Energetic Universe”. Its aim is to observe the hottest and most energetic phenomena in the universe with greater accuracy and intensity than ever before. It will address some key questions in astrophysics, including: How and why does ordinary matter assemble into galaxies? How do black holes grow and evolve and how do they affect their surroundings? After continuous industrial studies and significant parallel technology development efforts in phase A the project entered phase B1 by mid-2020 after successfully passing the mission formulation review. The developments related with the critical enabling technologies continue towards the Mission Adoption Review (MAR) and afterwards to phase C for manufacturing the flight module.

The Athena mission requires a new technology for the mirror, which collects and focuses the X-rays. It has to be bigger, lighter and with a better resolution than the mirrors of previous missions. For this, a new technology was invented: Silicon Pore Optics (SPO). The SPO technology was developed by the Dutch company cosine in cooperation with ESA. SPO achieves a much higher performance than the established X-ray mirror technologies and provides more than an order of magnitude better angular resolution for a given mass and effective area.

cosine, based in Sassenheim in the Netherlands, is the world leader in the production of these novel high-energy optics and will provide the SPOs as imaging optics for the Athena mission.

An important contribution to further improve the SPO production process for the Athena optics will be achieved by introducing Ion Beam Figuring (IBF). Ion beam figuring is a contactless high-vacuum process and a special type of ion beam etching. A focused broad beam of positively charged ions moves across the substrate surface and physically etches material by ion bombardment. With controlling the dwell time at a certain position, it is possible to precisely adjust the amount of material removal at each position of the substrate. This allows to correct thickness inhomogeneities and etch down to a uniform wafer thickness with an overall depth resolution in single digit nanometer range.

The high specification of the optics requires a very low Total Thickness Variation (TTV) and specific thickness gradient of the silicon mirror plates. scia Systems, a German manufacturer for ion beam and plasma equipment, can meet the requirements of the necessary improvements by ion beam trimming 300 mm silicon wafers with the scia Trim 300 system. As Athena needs almost hundred thousand of these densely packed mirror plates, a high throughput for wafer processing is needed. The scia Trim 300 is equipped with a handling robot for cassette loading, which means that up to 50 wafers can be automatically processed one after the other, without user interaction. At the request of ESA, a scia Trim 300 IBF machine capable of processing 300 mm wafers was installed at cosine. cosine is the first company in the world with the capability of IBF processing 300 mm wafers fully automatically.

scia Systems is pleased to have supplied cosine with the scia Trim 300, a reliable system for the challenging requirements of the Athena mission, as well as for other upcoming X-ray missions. In addition to those special optics purposes, the system is also suitable for various applications in MEMS manufacturing. More information about the scia Trim 300 and other possible applications of this system can be found here: www.scia-systems.com/trim-300.

About scia Systems

scia Systems is a supplier of advanced plasma and ion beam technologies for ultra-precise surface processing. Since 2013, the company has been developing equipment for processing microelectronics, optics for space research and biomedical applications. scia Systems is the world market leader of ion beam trimming technology. The best-known system, the scia Trim 200, is used worldwide for the production of high frequency filters in mobile communication.

With headquarters in Chemnitz, Germany, the company operates through partners in Europe, North America and Asia-Pacific. For more information about scia Systems, please visit www.scia-systems.com

About cosine

Since 1999, cosine has been developing and delivering innovative measurement solutions for space and industrial applications. At its headquarter in Sassenheim, The Netherlands, cosine operates 1.000 m2 of cleanrooms and high-tech assembly facilities to build and test the systems it develops for customers.

cosine’s High Energy Optics business unit is world-leading in the development and application of X-ray optics and systems. It combines and applies knowledge about semiconductor processes, silicon, glass and mass production to develop and produce light-weight, high-resolution X-ray optics. Those find applications ranging from space-based astro-physical applications to medical, semiconductor and material analysis systems used by industry and academia. For more information about cosine, see cosine.nl.

scia Systems is a supplier of advanced plasma and ion beam technologies for ultra-precise surface processing. Since 2013, the company has been developing equipment for processing microelectronics, optics for space research and biomedical applications. scia Systems is the world market leader of ion beam trimming technology. The best-known system, the scia Trim 200, is used worldwide for the production of high frequency filters in mobile communication.

With headquarters in Chemnitz, Germany, the company operates through partners in Europe, North America and Asia-Pacific. For more information about scia Systems, please visit www.scia-systems.com

scia Systems GmbH

Clemens-Winkler-Str. 6c

09116 Chemnitz

Telefon: +49 (371) 33561-0

Telefax: +49 (371) 33561-200

http://www.scia-systems.com

Sales Director

E-Mail: sales@scia-systems.com

Marketing

E-Mail: c.kendzia@scia-systems.com

![]()