Change? To be sure!

Role and task assignment saves time

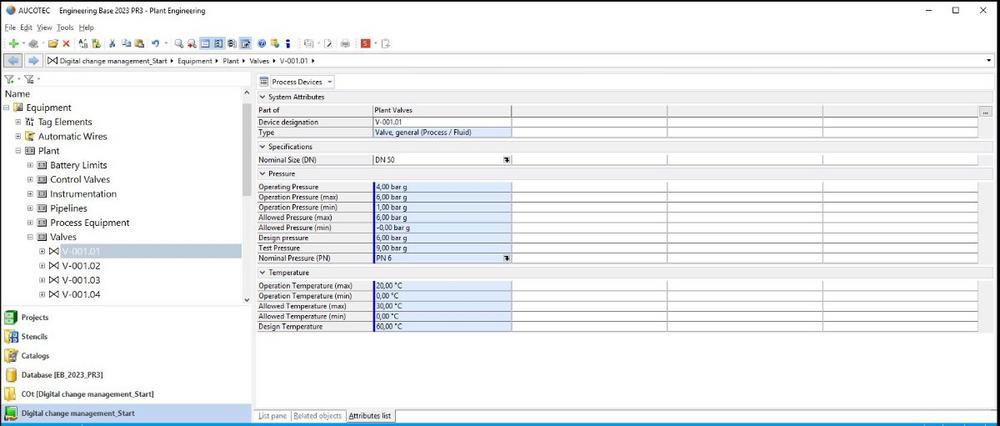

Important: Not only devices, but also attributes can be assigned a state in EB. Since devices often have 150 attributes and more, but by no means all of them are relevant to everyone, EB enables attribute assignment to specific users or roles. Whether automation, process or electrical engineers, a worksheet filter shows each of them only the appropriate aspects along with the open tasks in an instant. Groups or departments can also assign roles to themselves. This also works the other way around: If a process engineer needs a higher pump pressure, he can create tasks for those responsible for the next logical step. He leaves the reason in the change history. This keeps the information in EB’s data model on the object, instead of emailing and archiving Word documents. In the task, the objects to be checked are defined and assigned to a person or group. When opening "their" EB, the addressees see how many tasks are pending. Clicking on it takes you to a worksheet with the tasks and from there directly to the objects to be edited.

Customer-specific wizards can also be used to create tasks automatically, for example to automatically check certain data under defined conditions. For example, the complex interaction of checking, revision and release can be controlled automatically. This not only saves time, but also increases the quality of data and documentation.

Project overview saves revision runs

In addition, project management and other responsible parties can run state evaluations and get an overview of work progress via dashboard without having to be familiar with EB in detail. For example, a click displays how many attributes of the devices on a P&ID are checked and ready, i.e. whether the document is ready for revision. This saves EB unnecessary repeated revision runs.

More safety for operation

Operators of running plants also benefit. Maintenance tasks, for example, ensure that no maintenance is overlooked, and retrofitting tasks ensure that physical changes made by the technical team are incorporated promptly in the documentation. Only in this way can the digital twin always represent the current as-built state and retain its enormous value, even for retrofitting. Thus, EB’s extra control automatically brings extra quality to every phase of the plant’s life, and thus more safety.

BACKGROUND INFO

Up to date by nature

EB’s central data model already ensures "by nature" that all disciplines involved in the engineering process always work on the latest planning status, since each object exists only once and is edited directly from all discipline-specific views. Everyone sees what the "neighbors" have already created. However, because changes often occur after the fact, Aucotec’s development team introduced states some time ago, as well as the ability to use data tracking to immediately see when objects in their own area of responsibility have been changed. That alone is enough to make changes impossible to overlook. The new task assignment and role orientation now make change management even more efficient.

Aucotec AG has more than 35 years’ experience in the development of engineering software designed for use throughout the life cycle of machinery, plant equipment and mobile systems. Solutions range from flow diagrams and process-control/electrical technology for large-scale plant systems to modular on-board power supply units designed for the automotive industry. Software supplied by Aucotec is currently in operation throughout the world. In addition to the headquarters in Hanover, the Aucotec Group includes six other locations in Germany as well as subsidiaries in China, India, South Korea, the Netherlands, France, Italy, Austria, Poland, Sweden, Norway and the USA. What is more, a global partner network ensures local support all over the world.

AUCOTEC AG – EN

Hannoversche Straße 105

30916 Isernhagen

Telefon: +49 (511) 6103-0

Telefax: +49 (511) 614074

http://www.aucotec.com

Presse & Öffentlichkeitsarbeit

Telefon: +49 (511) 6103-186

Fax: +49 (511) 614074

E-Mail: Johanna.Kiesel@aucotec.com

![]()