Antibacterial Polyurethane Systems for Filter Production

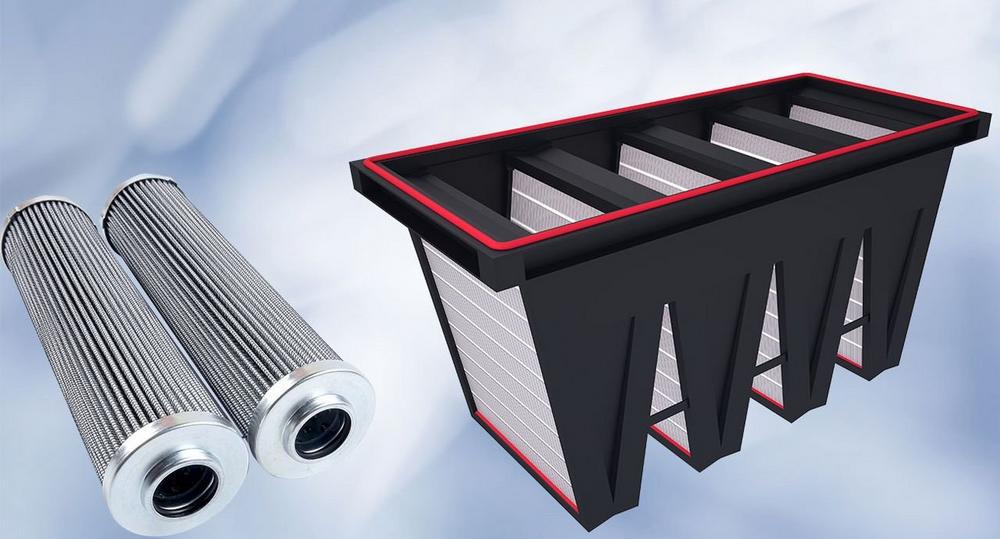

Antibacterial polyurethane systems developed by RAMPF Group, Inc. are used by leading manufacturers worldwide to seal and cast filters and filter components in heating, ventilation, and air conditioning systems (HVAC). The company’s product portfolio encompasses premium-quality systems that are tailored to meet the specific needs of customers.

RAKU® PUR Sealing Foams

Air filter elements are efficiently sealed using liquid and thixotropic FIPFG foams. The polyurethane systems feature fast processing and short curing times, first-class physical properties, excellent adhesion to metal and plastics, and are temperature resistant from -40 °C to +120 °C.

Product highlight at AHR Expo: Antibacterial foam gasket RAKU® PUR 32-3294-2

- Certified to the latest standard DIN EN ISO 846 (11/2020)

- Application to both to flat surfaces and inside grooves

- RAKU® speed technology for extremely fast cycle and handling times

- Top sealing quality in terms of IP requirements

- Extremely low water absorption

- Very low density, minimal material usage

- Excellent compression recovery

- Shore hardness is flexible and adjusted from Shore 00 40-70

- Suitable for both indoor and outdoor applications

RAKU® PUR Casting Resins

Compact casting resins are used to fix filter elements (e.g. end caps) in the filter frame. The silicone-free systems exhibit high mechanical strength, good flow characteristics and outstanding adhesive properties. Due to the good adhesion to plastic, especially ABS and PS, the connecting bridges of the filters can be used as a supporting element, which increases the stability of the filter elements.

Product highlight at AHR Expo: Antibacterial thixotropic casting resin RAKU® PUR 50-3030

- Excellent mechanical properties

- Rapid curing for very short process times

- High chemical, temperature, and impact resistance

RAMPF also offers conductive casting resins for filter elements that are used in ATEX environments (explosion-proof environments). These include soft (Shore A 85) and hard (Shore D 80) systems that are machinable, exhibit good flow, a conductivity of 0.03 MOhm/cm, and good chemical resistance.

Material and machine from a single source

RAMPF Group, Inc. stands for expert knowledge in both reactive resin systems and their processing, developing mixing and dispensing systems for sealing, casting, and bonding filters and filter elements. The company also offers first-class production capacities for sealing and casting.

RAMPF Group, Inc., based in Wixom, Michigan, USA, is a market-leading specialist for

> Mixing & dispensing systems for the reliable processing of polymers

> Two-component polymer systems based on polyurethane, epoxy, and silicone

> Modeling and mold engineering materials, in particular for the automotive, marine, and aviation industries

> Machine bases, machine frames, and other structural components made from mineral casting (polymer concrete)

RAMPF Group, Inc., is a company of the international RAMPF Group based in Grafenberg, Germany.

RAMPF Holding GmbH & Co. KG

Albstraße 37

72661 Grafenberg

Telefon: +49 (7123) 9342-0

http://www.rampf-group.com

Pressereferent

Telefon: +49 (7123) 9342-0

E-Mail: pr@rampf-group.com

![]()