HINODE and RAMPF Establish First-Ever Mineral Casting Production Facility in Japan

HINODE, founded in 1919, is a leading developer and manufacturer of iron and polymer concrete castings for civil engineering applications. By combining this encompassing casting expertise and highly modern facilities with the unrivalled mineral casting know-how of the RAMPF Group, the partnership will establish Japan’s first-ever production facility for the innovative epoxy-bonded material.

Takeshi Asai, CEO of HINODE – “Mineral casting is predominantly manufactured in Europe, the United States, and China; until now, there have been no manufacturing sites in Japan. With this partnership, we will increase the availability of mineral casting on the Japanese market, significantly decrease delivery times, and speed up the development and production of cutting-edge machinery. Together with RAMPF, the world’s largest manufacturer and a pioneer of mineral casting technology, we are providing machine builders in Japan with a truly unique offer for the production of machine beds and components.”

Yoshi Naganuma, CEO of RAMPF Group Japan – “We have been providing customers in Japan with an holistic service offering for the development and manufacture of customized multi-axis moving systems and basic machinery based on EPUMENT® mineral casting since 2005. With HINODE as our partner, we can now utilize the material’s enormous technical, economical, and ecological benefits even more effectively. We look forward to working together with the proven experts of HINODE and taking mineral casting in Japan to an entirely new level.”

Research and development collaboration with University of Tokyo

In addition to manufacturing mineral casting products at the HINODE factory in Tochigi, the business agreement encompasses a research and development collaboration with the mineral casting expert Professor Naohiko Sugita from the School of Engineering at the University of Tokyo. The objective is to further advance the quality and manufacturing process of mineral casting for the Japanese market.

Technical, economical, and ecological benefits

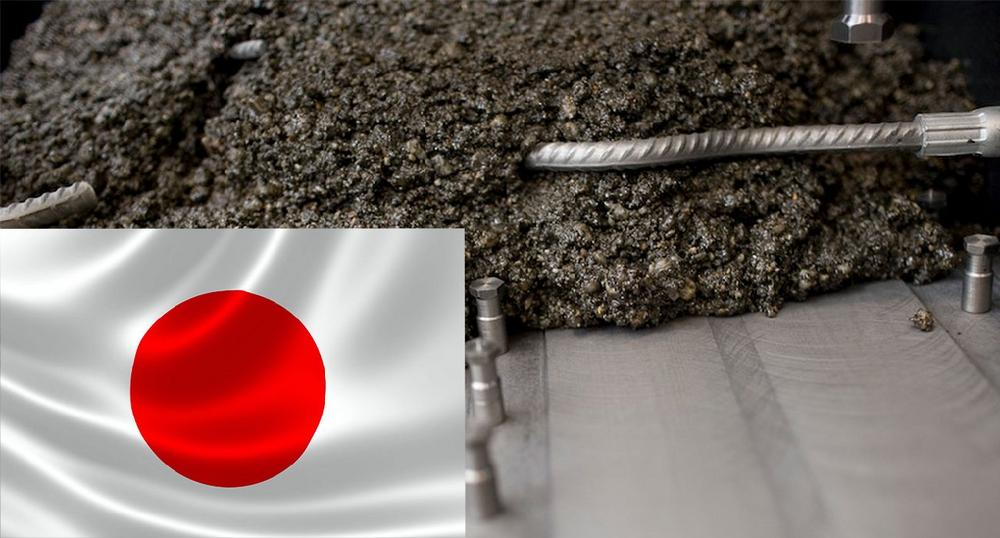

EPUMENT® mineral casting is a high-performance machine bed and construction material consisting of selected mineral fillers and a high-quality epoxy resin-based binding agent. The main benefits are:

- Outstanding damping qualities – the machine bed structure has greater dynamic stability in ultra-fast and high-precision production machinery; comparative measurements of the logarithmic decrement as a damping parameter show that mineral casting has a material damping capacity that is eight to ten times greater than metal materials such as gray cast iron and welded constructions.

- High degree of functional integration – the cold-casting process of EPUMENT® enables sensors, actuators etc. to be directly integrated into the machine bed, making these so-called “intelligent machine beds” an important prerequisite for the digitization of manufacturing processes (Industry 4.0).

- Resource-saving production, environmentally friendly disposal, and recycling – the manufacture of EPUMENT® consumes up to 75 percent less primary energy than cast metal; for a machine base weighing 10 metric tons, using mineral casting instead of gray cast iron implies a saving of 12,940 kg CO2e/t; EPUMENT® is more than 90 percent made up of naturally-occurring minerals and stones, so it can be disposed of and recycled as normal construction waste.

Engineering. Chemical. Service.

Your partner for reactive resin systems, machine systems, and lightweight construction with composites.

– Production and recycling of materials for modeling, lightweight construction, bonding, and protection

– Comprehensive range of solutions and services, particularly for innovative customer-specific requirements

– Technical production systems for precise, dynamic positioning and automation, as well as technologies for complex composite parts production

RAMPF Holding GmbH & Co. KG

Albstraße 37

72661 Grafenberg

Telefon: +49 (7123) 9342-0

http://www.rampf-group.com

Pressereferent

Telefon: +49 (7123) 9342-0

E-Mail: pr@rampf-group.com

![]()