Universal use: Wheel hub drives made by Framo Morat

Streamlined material flow or fully automated cleaning – powered by Framo Morat

Automated guided vehicles (AGV) and autonomous mobile robots (AMR) are the heart of automated warehouses. Controlled by intelligent software and communication, they improve the efficiency of material flow and contribute to end-to-end optimization of the value chain. To achieve the advantages of automated guided vehicles, it is important to select the right drive unit .

Wheel hub drives from Framo Morat are used as drive units in a wide variety of intralogistics applications. The modular and scalable system is a true jack of all trades that features impressively high and targeted performance in the smallest of spaces. This is why the wheel hub drives are the natural choice for other application areas that are currently being automated with sustainability in mind. One of these areas is the cleaning industry. Fully automated service and cleaning robots are cropping up in more places and becoming increasingly important. These systems have to navigate their surroundings and do this safely, making the challenges for these drive units very similar to those of mobile robots in intralogistics.

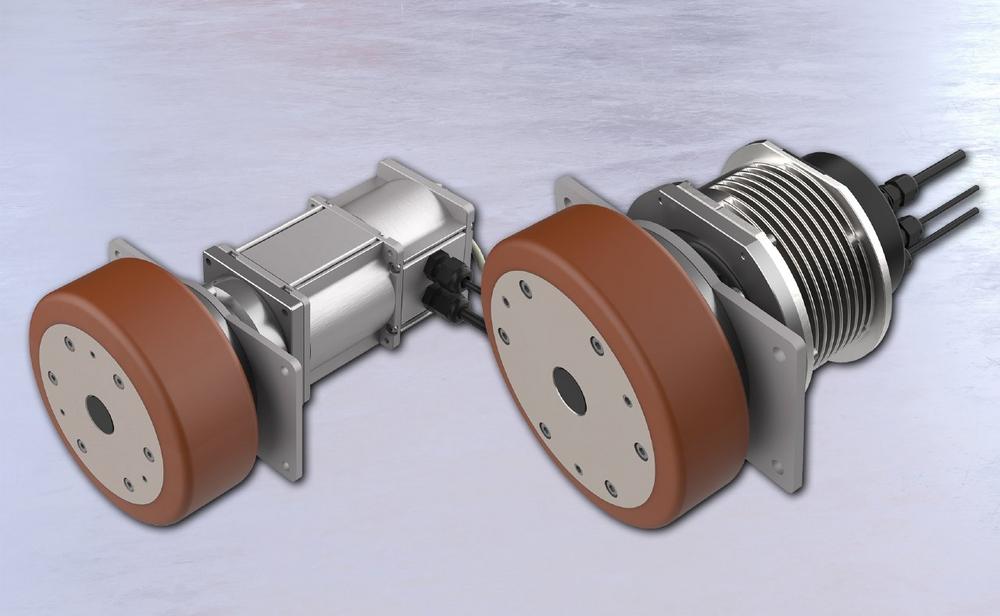

The Framo Morat wheel hub drive provides a solution to both sets of challenges. It combines all the functional elements into one all-inclusive design – including the PUR wheel, a high-precision planetary gear in 1- or 2-stage design, a high-performance BLDC motor, and the holding brake and electronics. For example, the durable CR700 cleaning robot made by Adlatus and designed for continuous loads uses RNA250 wheel hub drives.

End-to-end system solutions designed to meet specific requirements

The modular, scalable system of the wheel hub drive comes in different versions with uniform installation space and identical load capacities. The Standard version boasts a tried-and-true system that’s easy to use in vehicles due to its quick and simple plug-and-play setup. With this, AGV manufacturers have a system matched to the application, yielding either more compact vehicles with the same load capacity or increased usable installation space for batteries and electronics.

There are also two higher-tier versions, each of which adds more functionality than the previous. The Advanced system has an additional encoder and an integrated motor controller, which together enable intelligent control and evaluation of the systems. The Ultimate version has additional sensors for optimizing operation according to the application and enabling continuous data capture to improve the entire drive cycle.

Furthermore, if required, adjustments can be made with regard to the load capacity, torque and interfaces. Through the high degree of in-house vertical integration for the gear components, freedom in defining the motor characteristics and having their own assembly team, Framo Morat can also make short delivery times a reality for the wheel hub drives.

Standardized gears from a modular system

In addition to the wheel hub drives, Framo Morat has the NG250 and NG500 platform hub gears in its portfolio. For quick setup, both hub gearboxes are available in a 1- or 2-stage design with the PUR wheel. Standardized flanges make it possible to connect most motors directly to the hub gearboxes. This enables quick availability and a high degree of flexibility. Customer-specific adaptations can be accommodated, such as a brush seal for outdoor applications or a toothed belt for use in high-bay warehouses.

When it comes to gears, Framo Morat has unlocked the maximum power density of the hub gears. These gears prove their worth, particularly in wheel drives for automated guided vehicles, thanks to their favorable arrangement of the separate wheel bearings and planetary gear integrated in the wheel. A remarkable example of this is the Open Shuttle made by KNAPP, which was designed in cooperation with Dunkermotoren. It is equipped with an NG500 hub gear in conjunction with the BG 75 BLDC motor that features an integrated brake and two encoder systems.

Framo Morat will be exhibiting at LogiMAT: Hall 6 – Booth C02

LogiMAT will be taking place from April 25–27, 2023, in Stuttgart and Framo Morat will be showcasing its entire selection of drive components and systems for intralogistics as well as wheel hub gears at Stand C02 in Hall 6. A. To mention just a few: rotor shafts for electric motors of industrial trucks, Compacta series gear motors for gate drives in automated high-bay warehouses, planetary gears for drum motors, spindle lifting gears for cranes and lift trucks, and customer-specific drive systems for electric pallet stackers based on our proprietary speeroX gears.

The CR700 service robot, equipped with the RNA250, is a noteworthy highlight at the trade show and can be viewed at Adlatus‘ Booth B59 in Hall 10, right next to the Framo Morat booth. Dunkermotoren will be presenting the Open Shuttle made by KNAPP at Booth B09 in Hall 7.

With 110 years of experience in gear technology and drive engineering, the Franz Morat Group combines expertise in metal-cutting gear technology and plastic injection molding technology under one roof. The components and drive systems, most of which have been developed specifically for the customer, are used in such fields as mechanical engineering, rehabilitation equipment technology, intralogistics and the automotive industry. For the booming E-Motive sector, the equal joint venture Morat Swoboda Motion (MSM) was founded with automobile supplier Swoboda in 2018. The Franz Morat Group, including MSM, has more than 700 employees and operates subsidiaries in the US, Poland, Mexico and Turkey.

https://franz-morat.com/

Framo Morat GmbH & Co. KG

Franz-Morat-Straße 6

79871 Eisenbach / Hochschwarzwald

Telefon: +49 (7657) 88-0

Telefax: +49 (7657) 88-333

https://de.framo-morat.com/

Marketingleitung Franz Morat Group

Telefon: +49 (7657) 88-566

E-Mail: s.federer@framo-morat.com

Business Development Intralogistics

![]()