Signal integrity pre-programmed: Fixture and adapter construction by ProMik

ProMik fixtures: Plug & Play for highest signal integrity

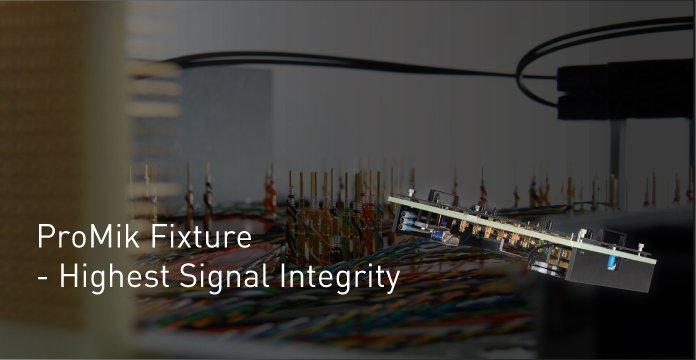

ProMik fixtures and adapters are used by a number of well-known test handler manufacturers, among others, who rely on high-speed transmission rates. To effectively and efficiently counteract the impact of high frequencies on programming quality, the system experts focus their expertise on in-house fixture and adapter development. With the highest signal integrity, the solutions ensure significantly reduced cycle times and increased output. This high level of quality is made possible by the robust and repeatedly tested wiring, on which ProMik has focused its attention.

Fully comprehensive tests in the application environment and given equipment enable the ProMik adapter and fixture construction to be integrated smoothly into specific production lines. For the quick replacement of the fixtures, neither adjustments nor tools are required. In addition to the smooth Plug & Play functionality, the individual configurability of the adapters, e.g. through additional test hardware, sensors, stroke counters or scanning technology such as barcode readers, is also convincing. ProMik fixture customers benefit from particularly short delivery times thanks to quick design and production processes. However, this does not detract from the proven quality of the specialized company: With dedicated quality tests and inspections, for instance strain gauge and FEA, error sources in ProMik products – made in Germany – are excluded completely.

Technical features and range of services

ProMik develops and manufactures with strong customer focus: The service portfolio includes, depending on circumstances, the complete adapter installation as well as the wiring and final testing as separate services. ProMik also highlights its special proximity to practical implementation in fixture construction through connectivity: The adapters facilitate single-sided, double-sided as well as two-stage and lateral connection. Encapsulated components can also be connected by using ProMik adapters. Overall, connection up to 50 mil with a test point diameter of up to 0.5 mm is possible with ProMik’s adapter and fixture construction.

From the technical details to comprehensive service: ProMik is committed to the highest standards of precision, reliability, and application-specific expertise in finding solutions. Thanks to a well-coordinated team of experienced specialists, the area of expertise extends over various application areas, which covers ProMik not only with highly developed products, but also with comprehensive services. Regardless of the way customers wish to reduce their cycle times and increase their production rate: The experts at ProMik use their know-how to create perfectly integrated, tailor-made solutions.

ProMik GmbH provides solutions in the field of flashing and testing of electronic components up to entire electrical control units. Since its foundation in 1995, ProMik represents the technology leader in its industry. In addition to flashing and testing, the product and service portfolio also includes cyber security consulting as well as its implementation, bootloader development and fixtures. ProMik’s main industries are automotive, consumer products, industrial, aero and more. Especially the proximity to the user, the high practical focus and the specialized know-how are valued by numerous well-known customers across all industries.

ProMik – Programmiersysteme für die Mikroelektronik GmbH

Südwestpark 100

90449 Nürnberg

Telefon: +49 (911) 252665-0

Telefax: +49 (911) 252665-66

http://www.promik.com

Marketing

Telefon: +499112526650

E-Mail: press@promik.com

![]()