Forming of Advanced THT-Interconnects using SB² Laser Solder Jetting Process

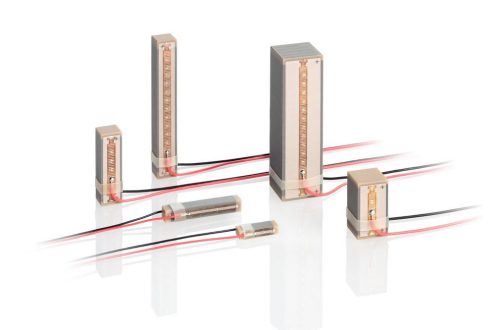

SB² laser assisted solder jetting process addresses these challenges and overcomes them. The process involves jetting a molten solder droplet onto a THT contact. The solder fills the cavity between the pin and the inside of the vertical interconnect access (VIA), forming a reliable mechanical and electrical connection. This pitch-agnostic process works for various 2D and 3D geometries. It has several critical advantages over wave soldering, the conventional industrial solution to soldering THT contacts. Beside the optional use of flux, it supports suitable pitch applications, as the usable solder ball material size can be downscaled to 30 µm. Moreover, it is a gentler process regarding the thermal impact on the substrate. Thermal damage to sensitive substrate parts can be avoided as the substrate heating via contact with the molten solder is highly localized. Furthermore, previous work has proven that interconnect bonds created in such a way are much more resilient against the effects of thermal aging. This is because the thermal event is shorter by 2-4 orders of magnitude compared to the conventional oven-reflow, solder-iron, or wave soldering bonding processes.

In this work, we created PTH and NPTH THT-contact samples of different geometries and aspect ratios showing various pad metallization (Cu, NiAu, or HASL) and which we then processed with the SB²-Jet method. The resulting test vehicles were subjected to extensive analyses, including microscopic inspection of the bond geometry and X-ray analysis. In addition, the impact on the soldered contacts before and after thermal cycling was microscopically inspected along with metallurgical analysis through cross-sectional polishing.

A model for determining the filling level using a visual scanning system was demonstrated, making the costly and time consuming X-ray analysis or cross-sectional preparation obsolete. Finally, this novel approach’s industrial potential and technological significance are covered, providing an outlook on future technological developments.

You can view the enitre publication here at this link.

Released by:

Matthias Fettke, Gero Bonow, Anne Fisch, Moshir Nasser, Georg Friedrich, Rojhat Baba, Thorsten Teutsch

PacTech – Packaging Technologies

Am Schlangenhorst 7-9, 14641 Nauen, Germany

Fettke@pactech.de

PacTech is a technology-focused company specialized in advanced packaging equipment manufacturing and wafer level packaging services. Since our establishment, our team has been working relentlessly on developing new leading-edge technologies for the next generation applications. We are known to be highly adaptive to customization and unique applications. Our team of technical experts is striving to resolve various packaging challenges faced by the industry to provide our customers and partners more competitive solutions in terms of cost, time-to-market, and technology advancement. Our headquarter is located in Nauen, Germany with two operation and manufacturing sites in Santa Clara, CA, USA and Penang, Malaysia. Together with our sales and field service teams across the globe, we can cater to the demand within your region.

Pac Tech – Packaging Technologies GmbH

Am Schlangenhorst 7 – 9

14641 Nauen

Telefon: 033214495122

Telefax: +49 (3321) 4495110

https://www.pactech.com

Business Unit Manager Service & Application

E-Mail: fettke@pactech.de

![]()