Integrated measuring system guarantees exact travel distances

SCHNEEBERGER E-SHOP https://shop.schneeberger.com/

Easy product selection – quick delivery – reliable order processing

With our entry into the digital world, we offer our customers the opportunity to obtain comprehensive information about our products. Technical data, prices and delivery times can be viewed at any time in our SCHNEEBERGER E-SHOP. We supply our customers throughout Europe, as well as in Switzerland and Great Britain.

For us, the focus is not only on fast delivery, but also on the fact that we want to give our customers the opportunity to get the product they want in the shortest possible time and, true to our corporate vision, to support the sustainable growth and success of our customers.

Register today and become part of our digital world.

The SCHNEEBERGER E-SHOP world is yours!

Your advantages at a glance

- Quick-Delivery Service (delivery within two to five working days)

- Individually configurable product options, e.g. system length, accuracy class

- Payment by credit card, direct debit, invoice, prepayment

- Reliable order processing

- Security through personal access and SSL encryption

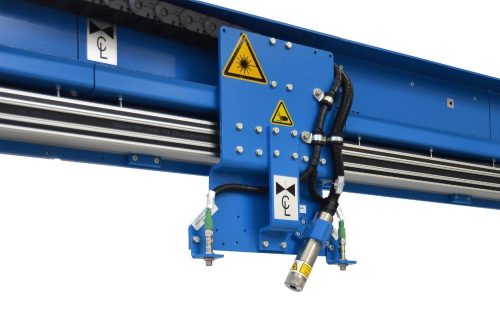

For over 15 years, SCHNEEBERGER has been developing compact, integrated distance measuring systems for its MONORAIL guideways and today, sets the standard in terms of accuracy, design, installation, adjustment, operation and maintenance. A variety of interfaces to all major control systems, depending on the AMS version, are available.

Quiet, low-vibration, and low-friction linear travel are essential in sophisticated mechanical engineering systems. This applies to automated applications in metrology, as well as in the semiconductor, biotech, medical devices, machine tools, laser processing, and many other branches of industry. SCHNEEBERGER provides high-quality MONORAIL guideways to serve as the perfect basis for such applications.

The integrated AMS distance measuring system from SCHNEEBERGER can be perfectly integrated into MONORAIL guideways – both roller guideways and ball guideways – and ensures exact travel distances with tolerances of ±5 µm/m.

Mineral Casting: Vibration-Free Precision with Environmental Responsibility

Unlock the Potential of High-Precision Applications with Mineral Casting

Mineral casting features clear technological, economic and ecological advantages over steel, gray cast iron or cast iron. Its excellent vibration damping, chemical resistance and thermal stability not only impress users in machine tool manufacturing, but also in many other industries such as medical technology, solar technology, electronics and packaging. In particular, the combination of linear technology and mineral casting creates essential customer benefits.

SCHNEEBERGER is a leading global manufacturer of mineral castings and not only offers innovative and high-precision mineral casting solutions, but also completely pre-assembled modules and assembly groups, equipped with the following components according to customer requirements

- linear guideways

- linear motors

- electronics and sensors

- drive units

Since we offer everything as a one-stop solution, we guarantee optimal matching of the various components. SCHNEEBERGER mineral castings are manufactured by specialized employees in our production facilities in Czech Rep. and China. The entire process, from the design phase to the actual casting process and finishing, is subject to strict quality specifications. This guarantees that complex machine designs and assemblies with integrated guides are manufactured in the specified dimensions and to the highest quality.

Mineral casting is the ideal material for use in any supporting structures and foundation structures where dynamic and highly precise movements are required. It exhibits clear technological, economical and ecological benefits in comparison to steel, grey cast iron and cast iron. It isn’t just the attention of machine tool producers which is piqued due to the material’s excellent vibration damping properties, resistance to chemicals and thermal stability; medical engineering, solar technology, electronics, and packaging companies as well as many other branches are also convinced by the advantages of mineral casting.

SCHNEEBERGER can supply the right mineral casting to suit every purpose, regardless of whether it weighs 80 grams or 30 tons.

MONORAIL BM profile rail guideways with balls or with rollers

The MONORAIL MR profile rail guideways with rollers: when the heaviest loads in milling, turning, drilling or grinding machines need to be moved in an accurate manner, reliable linear bearings are one of the elements required for this. SCHNEEBERGER has the right solution in the form of its MONORAIL MR series, which is intended for various types of application and weight class. As such, workpieces weighing up to 150 tons can be moved in an extremely precise manner.

The MONORAIL BM profile rail guideways with balls have been an important component of the SCHNEEBERGER product range for many years. Now the product range has nearly doubled by the addition of new BM carriage types, featuring low and short versions. This opens up numerous new areas of application.

Easy mounting of carriages on the profile rail

https://youtu.be/bH8GGnEonOE?si=w4cTzExyvbe8dwSh

Ball screws for demanding applications

The Schneeberger ball screws (SBS) are impressive due to their precision and efficiency, which the ground and hardened ball contact surfaces are primarily responsible for. The SBS are therefore equally suitable for use at high and low speeds as well as oscillating short stroke movements. This makes them particularly attractive for demanding applications in machine tools as well as measuring and testing technology.

Schneeberger is expanding its extensive linear technology portfolio with the new SBS ball screws. Always in focus: optimum precision and economic feasibility. In order to ensure these characteristics over the long term, the ball bearing raceways, bearing seats and contact surfaces of the ball screws are precision ground. The spindle outer diameter that is ground with the bearing seats in the same clamping process combines a two-fold benefit. Sven Vitt, the SBS Project Manager at Schneeberger, explains: "On the one hand, the ball screw can be aligned to the spindle outer diameter, and on the other hand, the efficiency of the wiper systems is significantly increased." Vitt ascribes equal importance to the induction-hardened spindle and the through-hardened nut.

Overall, the precise and hard ball contact surfaces enable optimum force transmission with extremely high positioning and repeat accuracy. In addition, Schneeberger ball screws stand out due to their quiet, torque-constant running behavior. Equally important are the accompanying low heat generation, minimal wear and long service life.

All these characteristics set new standards for use in demanding sectors, including the machine tool industry, measurement and testing technology, drive and process technology as well as robotics and automation. Depending on requirements, the SBS is available with spindle diameters of 32 mm, 40 mm, 50 mm and 63 mm. The manufacturer specifies a maximum thread length of 2,000 mm for all sizes. The implementable increases in speed are 1.5 g and the maximum speeds 96 m/min. The accuracy class according to ISO – type P is IT3. Schneeberger application technicians and engineers are always ready to assist with the evaluation and design of customer projects.

SCHNEEBERGER group

SCHNEEBERGER® serves original equipment manufacturers operating (OEM) in various industries worldwide – from machine tool, solar technology and semiconductor technology to electrical engineering and medical engineering and others. Linear bearings, profiled linear guideways, measuring systems, gear racks, slides, positioning systems and mineral casting are all part of SCHNEEBERGER’s product and manufacturing range.

SCHNEEBERGER AG

St. Urbanstrasse 12

CH4914 Roggwil

Telefon: +41 (62) 91841-11

Telefax: +41 (62) 91841-00

http://www.schneeberger.com

Pressekontakt

Telefon: +41 (62) 9184-302

E-Mail: rosalia.haller@schneeberger.com

![]()