NUM FlexiumPro CNC-System

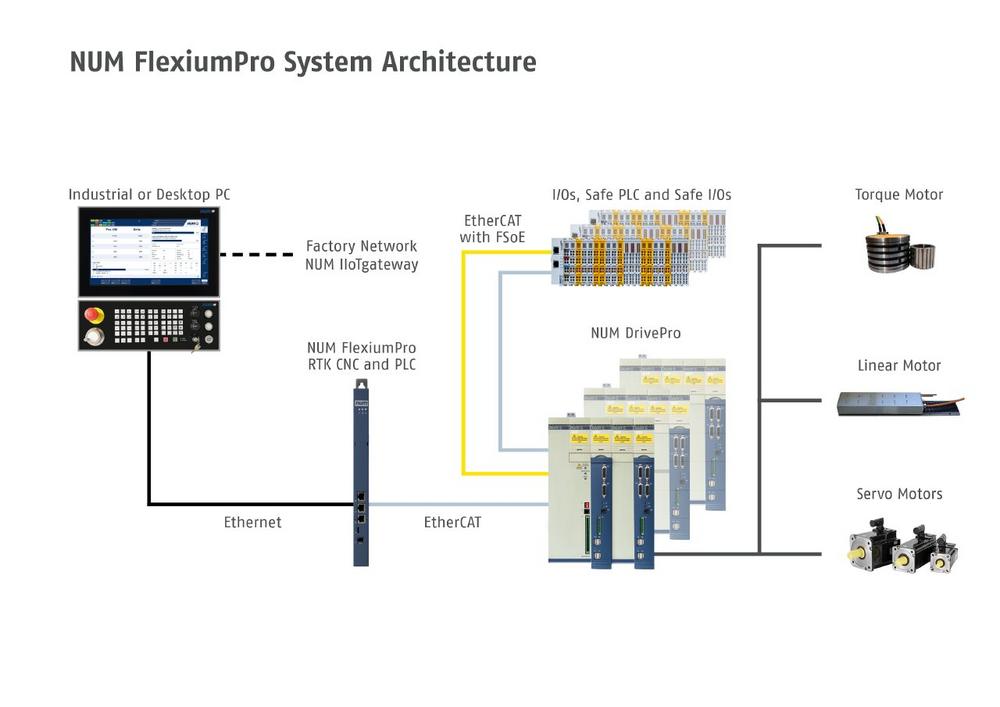

Let’s first have a look at the hardware configuration. The CNC system basically consists of a Real-Time Kernel (RTK), which integrates PLC and CNC, servo drives (NUM DrivePro), servo motors, a PC, and various accessories. The use of a NUM industrial PC is recommended but not mandatory. Both the RTK and the servo drives use the latest system-on-chip technology with an ARM multi-core processor. The resulting extremely high degree of integration leads to an enormous reduction in components, which positively affects the reliability and availability of the system. In addition, the computing power has been massively increased compared to the Flexium+. The FlexiumPro CNC is more than 10 times faster than the Flexium+. All data, such as the PLC program, workpiece programs, machine configuration, calibration data, etc., are stored on a replaceable microSD card, and the safe shutdown of the CNC system is ensured, even in the event of a power failure, by a built-in super-capacitor.

The peripheral devices, such as I/O modules or safety components, are identical to those of the Flexium+. The servo drives (NUM DrivePro), when equipped with the NUM-SAMX option, have all the required safety functions: Safe Torque Off (STO), Safe Stop (SS1/2), Safe Operating Stop (SOS), Safe Limited Speed (SLS), Safe Limited Position (SLP), Safe Direction Monitoring (SDM), and Safe Cams (SCA). In addition, the Safe Brake Control (SBC) function is available as default.

The size of the CNC system has been significantly reduced. For example, the fanless RTK is now only half the width of the Flexium+, and a quad-axis version is available for the servo drives in addition to the mono-axis and bi-axis versions.

The software of the CNC system consists of various components. All software modules have been adapted and optimized for the modern hardware architecture, allowing maximum performance to be extracted from the hardware. For example, to avoid latency and overhead, the servo drives completely dispense with an operating system between the CPUs and the “actual software” – it is pure hardware programming. As a result, even with the quad-axis module (4 axes), a sampling time in the position control loop of only 50 µs is achieved.

Although the FlexiumPro is a completely new control generation, particular care has been taken to ensure that it is as compatible as possible with the Flexium+ for the user, allowing for seamless migration. This also means that the FlexiumPro has all the functions and flexibilities of the Flexium+. For example, the PLC programming languages and environment of FlexiumPro (CODESYS V3) are identical to those of Flexium+, and the part programs are upward compatible.

The HMI of the FlexiumPro system differs from that of the Flexium+ system and focuses on interoperability with the user (touch, keyboard, and hardware buttons). Another significant strength of the new HMI is its flexibility. Thanks to a powerful SDK (Software Development Kit), the FlexiumPro HMI can be customized, extended, modified, and personalized. Users can easily integrate customized FlexiumPro HMI modules into the HMI or customize the predefined plug-in HMI components according to their needs. Multi-HMI configurations (one machine with more than one HMI) are also supported, as is the Flexium 3D simulation software. During the simulation of the part program, the user can see the simulation of machine movements, material removal from the workpiece, and possible collisions during the simulation of the part program, the user can see the simulation of machine movements, material removal from the workpiece, and possible collisions between machine components, workpiece, and tool.

The NUM IIoTgateway, which is based on modern Industry 4.0 technologies, also enables seamless integration of FlexiumPro into the manufacturing environment.

Thanks to its flexibility, scalability, and configurability, as well as its high energy efficiency, the FlexiumPro system is suitable for automating a wide range of machines. This spectrum almost certainly includes your machine, whether it is a retrofit or a new machine. Our subsidiaries will be pleased to support you in the investigation and automation of your machine.

NUM is active in social media. To become a follower visit:

https://www.linkedin.com/company/num-ag/

https://www.facebook.com/NUM.CNC.Applications

https://twitter.com/NUM_CNC

https://www.youtube.com/num_cnc

NUM AG

Battenhusstrasse 16

CH9053 Teufen

Telefon: +41 71 335 04 11

Telefax: +41 71 333 35 87

https://www.num.com/

Telefon: +41 71 335 04 11

E-Mail: sales.ch@num.com

![]()