Additive manufacturing: Schaeffler acquires Belgian startup Aerosint SA

- Schaeffler buys Aerosint SA from U.S. firm Desktop Metal, strengthening its market position in additive manufacturing technologies

- “Schaeffler Aerosint SA” to be integrated into the Schaeffler Group as an additional Schaeffler Special Machinery location

- Innovative coating technology using power-based laser fusion makes additive manufacturing cost-effective

The global motion technology company Schaeffler is strengthening its know-how in additive manufacturing technologies with the acquisition of Belgian startup Aerosint SA from Desktop Metal, a leading U.S. manufacturer of innovative 3D printing systems. Both parties have agreed not to disclose details of the transaction. Additive manufacturing is simpler than conventional manufacturing processes when it comes to producing components with complex geometries. A key enabler of Industry 4.0, it also offers a number of sustainability benefits, including reduced material consumption, greater energy efficiency in production, and material options that are more environmentally friendly. The startup will be renamed “Schaeffler Aerosint SA” and integrated into the Schaeffler Group as an additional location for Schaeffler Special Machinery.

Andreas Schick, Chief Operating Officer at Schaeffler AG, commented on the deal as follows: “Schaeffler Aerosint SA offers the first industrial solution for simultaneous, metallic multi-material printing. This expertise, combined with our high level of industrialization competence and decades of know-how in innovative production technologies, will give us a decisive market advantage. The acquisition is an important milestone in the industrial use of metal-based additive manufacturing processes in the area of Industry 4.0.”

Innovative powder coating technology for new material combinations

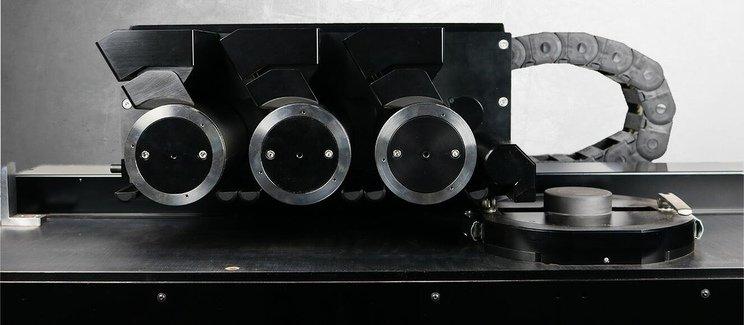

Powder-based laser fusion (L-PBF) is a more innovative, efficient and sustainable way of manufacturing components for applications such as tools, prototypes, or small-series production runs. The patented Selective Powder Deposition (SPD) technology of Aerosint makes it possible to create homogeneous layers comprising multiple adjacent material deposits. The deposition is selective, meaning that the required amounts of the right materials are deposited at the required locations. The multiple material powders are kept separate and deposited by what are known as “recoaters”. These work like carriages in normal office printers, “printing” 3D components at lateral powder pixel resolutions of up to 300 μm. This SPD technology, which is already on the market, can be used with additive manufacturing processes such as laser powder bed fusion and binder jetting, as well as with indirect processes. Schaeffler Special Machinery will incorporate it into its system for multi-material 3D printing, which will be available from 2024. “By integrating this key future technology, Schaeffler Special Machinery, as a partner for production excellence, will be able to offer its customers a more diversified portfolio of systems, particularly for the manufacturing and medical technology sectors,” explained Bernd Wollenick, Senior Vice President Schaeffler Special Machinery.

Aerosint was founded in 2016, is based in Herstal, Belgium, and has 19 employees. It was acquired by Desktop Metal in 2021. Ric Fulop, Desktop Metal’s founder and CEO, said Aerosint’s technology has a nearer term roadmap with laser systems and Schaeffler can make immediate use of the technology. “With Schaeffler, we have an international partner with a high level of technology expertise and clear roadmap for commercializing the SPD technology with laser-based systems. We will continue to collaborate on the various possibilities for using this technology in Desktop Metal binder jetting systems in the future.” In addition, Schaeffler and Desktop Metal will continue their collaboration in multi-material solutions, including in the area of toolless manufacturing technologies.

Schaeffler Group – We pioneer motion

The Schaeffler Group has been driving forward groundbreaking inventions and developments in the field of motion technology for over 75 years. With innovative technologies, products, and services for electric mobility, CO₂-efficient drives, chassis solutions, Industry 4.0, digitalization, and renewable energies, the company is a reliable partner for making motion more efficient, intelligent, and sustainable – over the entire life cycle. The motion technology company manufactures high-precision components and systems for drive train and chassis applications as well as rolling and plain bearing solutions for a large number of industrial applications. The Schaeffler Group generated sales of EUR 15.8 billion in 2022. With around 84,000 employees, the Schaeffler Group is one of the world’s largest family-owned companies. With more than 1,250 patent applications in 2022, Schaeffler is Germany’s fourth most innovative company according to the DPMA (German Patent and Trademark Office).

Schaeffler AG

Industriestraße 1-3

91074 Herzogenaurach

Telefon: +49 (9132) 82-0

Telefax: +49 (9132) 82-3584

http://www.schaeffler-group.com

E-Mail: daniel.pokorny@schaeffler.com

![]()