A longstanding partnership on an equal footing – GROB-WERKE and Mandatec AG

First contact over a decade ago

In 2013, the Mandatec team visited EMO in Hannover, where they first came into contact with GROB’s universal machining centers. The innovative concept of a horizontal 5-axis machine with a spindle tunnel immediately captured their interest. However, initial concerns arose at Mandatec regarding potential chip accumulation in the tunnel. As a supplier to the machinery and hydraulic industries, Mandatec places great importance on a high level of automation with minimal manual effort. Reliable chip disposal is crucial for smooth operation. After numerous detailed discussions and internal deliberations, Mandatec ultimately decided to collaborate with GROB, ordering the first two machines, two 5-axis universal machines G550. The machines were delivered in October 2015, marking the beginning of a close partnership that would further grow in the subsequent years.

One year later – three more machines

Just a year later, in the fall of 2016, Mandatec ordered three additional G550 machines from GROB. The decision was multifaceted: while Mandatec had a somewhat bumpy start with the first two machines, they received excellent support from GROB with comprehensive expertise and service. Additionally, Mandatec was fully convinced of the GROB machine concept, especially regarding flexibility. At that point, Mandatec stood at a crossroads and decided to go all-in. The Swiss company sold all existing machines, making room for the GROB machines and thereby placing tremendous trust in the Bavarian machine builder. This move, however, paid off, leading to a significant increase in the productivity of the machine park with uniform programming, maintenance, and a single service partner. Today, it is evident that Mandatec made the right choices by selling the old machine park and acquiring GROB machines.

Production around the clock

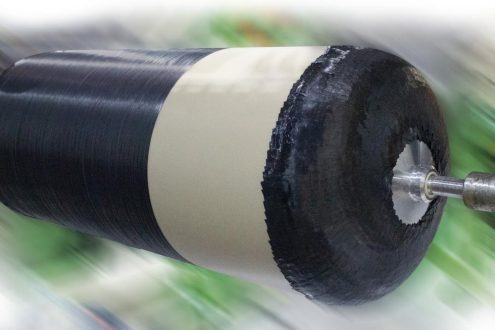

Since then, Mandatec has been practically operating the five machines around the clock in single-shift operation. The Swiss company appreciates the high reliability and repeatability of the machines. The ability to produce unmanned at night and deliver high-quality parts in the morning is one of the key reasons why Mandatec chose GROB technology. Additional benefits such as free chip fall, overhead processing, and a maximum tool length of 465 mm make GROB machines the optimal solution for Mandatec, and these features are not taken for granted in this machine size. Collision freedom, which significantly simplifies programming, is also a major advantage for Mandatec. Even with the maximum tool length and the largest possible workpiece, the tool completely disappears in the tunnel, eliminating collisions during the swiveling movements of the A and B axes, which need not be considered.

Expansion of the GROB machine park at Mandatec continues

"We see the same advantages with the two recently ordered G520F from GROB. The specific requirement in one of our customer projects was a significantly increased number of identical products. A double-spindle machine proved to be the most economical solution. Despite the separate and independent Z-axes, adjustable spindle distance in the X-direction, and parallel measurement with a 3D probe, the machines do not lose flexibility," says Marcel Sütterlin, CEO of Mandatec.

The two new machines will expand Mandatec’s production from the end of 2024. In the initial phase, the new machines will manufacture various hydraulic blocks, which will then be mechanically deburred and cleaned with a high-pressure water jet. The planned robot loading will also achieve a high level of automation in these systems.

To ensure the necessary high availability of the systems, a flexible and responsive service structure is essential. GROB offers an optimal service with fast response times and smooth communication, ensuring that service technicians make every effort to resolve downtimes as quickly as possible and get the machines back into operation.

CEO German Wankmiller visits Mandatec

Due to the expansion of the machine park to nine spindles, all supplied by GROB, Mandatec received a surprise visit from German Wankmiller, CEO of GROB-WERKE. German Wankmiller and Adrian Gasser (Owner of Mandatec AG) have had a strong understanding since the beginning of their collaboration over ten years ago, utilizing their joint meetings for stimulating exchanges. "We see GROB as a reliable partner who operates with us on an equal footing. For over ten years, GROB has been able to fully meet our needs before, during, and after the purchase," says Adrian Gasser. German Wankmiller is also proud of the long-standing collaboration: "A partnership on equal terms is enormously important to us. Mr. Gasser and I have known each other for many years; I am very proud of this long-term customer relationship. Such long customer relationships show us that we are doing the right thing with our products and services, satisfying our customers over the years."

GROB-WERKE GmbH & Co. KG

Industriestr. 4

87719 Mindelheim

Telefon: +49 (8261) 996-0

Telefax: +49 (8261) 996-268

http://www.grob.de

Marketing, Junior Technical Marketing Managerin

Telefon: +49 (8261) 996-2089

E-Mail: emely.merkle@grob.de

![]()