Anuga FoodTec: KHS systems combine efficiency with safety

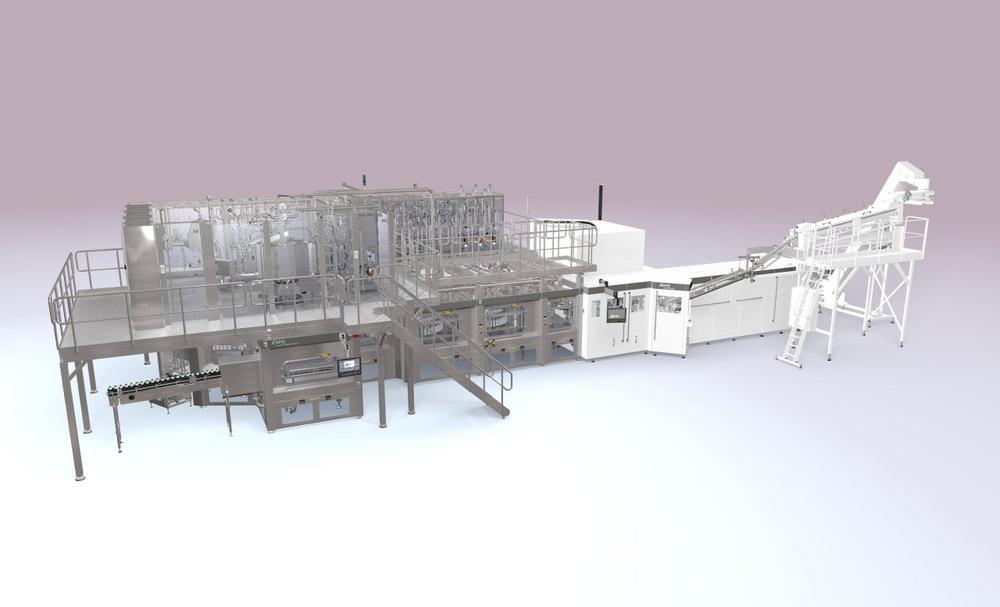

“Economic success calls for maximum efficiency and availability in all filling and packaging processes. We provide innovative and resource-saving systems and solutions that fully satisfy all aspects of this demand,” says Tobias Wetzel, CSO of KHS. The most recent example of this is the new rotary InnoPET BloFill ACF-R aseptic block that combines the energy-efficient InnoPET Blomax Series V stretch blow molder with the rotary Innofill PET ACF-R filler for the very first time.

Linear fillers can process up to 14,000 bottles per hour. In contrast, the rotary aseptic block has a capacity of up to 36,000 1.0-liter bottles per hour and in the future is even to be available with a top output of 48,000 500-milliliter bottles an hour. The new plant engineering achieves a sterility of log 6 inside the bottles – which is equivalent to a reduction in germs of 99.9999%. “Our linear aseptic fillers, also blocked, have long proved themselves in practice in the filling of sensitive beverages into PET bottles, where maximum safety is of the essence. The newly developed rotary aseptic filler in the higher capacity range is thus the next logical step. With this, we also want to set standards regarding the machine’s hygienic properties,” Wetzel promises.

Effective protection for sensitive beverages

Here, KHS consciously focuses on bottle sterilization that – unlike preform sterilization – can also be combined with the KHS FreshSafe PET coating system and thus offers additional barrier protection for sensitive beverages. On this variant all potential germs are removed from the containers directly prior to filling. This process gives bottlers more flexibility and greater availability during format changeovers than preform sterilization, as here changing the stretch blow molds disturbs the sterile state of the block.

While on the subject of barrier protection … KHS visitors to the exhibition can also look forward to discovering the latest generation of Plasmax coating technology. With this pioneering technique a wafer-thin layer of chemically pure glass is applied to the insides of PET bottles, with bottle recyclability nevertheless fully retained. This protects sensitive products such as fruit juice, wine, beer, soft drinks, ketchup, sauces and other liquid foods from oxidation and loss of CO2, meaning that they keep for considerably longer.

KHS has continuously improved this procedure over the years and now brought it up to the next level. The result is better performance, quality and flexibility and a higher degree of efficiency.

Consistent expansion of the digital service portfolio

In addition, the turnkey supplier’s range of digital services is now to be supplemented by KHS ConnectApp that provides two major extra benefits:

- Data-based transparency regarding the key line performance indicators and help with decision-making processes.

- Support with system operation.

The first KHS ConnectApp function is the Guide module that with its interactive work instructions and powerful notification management system helps to ensure trouble-free workflows during inspection and maintenance or when training up new employees, for instance. Moreover, all work steps can be documented with the app.

“By expanding our digital service portfolio, and especially thanks to the introduction of KHS ConnectApp, we’re laying the foundations for further optimization and efficient organization of the entire system operation and management,” explains Wetzel.

The KHS Group will be presenting its plant engineering at Booth B070 C089 in Hall 5.1 at Anuga FoodTec in Cologne, Germany, from March 19 to 22, 2024.

The KHS Group is one of the world’s leading manufacturers of filling and packaging systems for the beverage and liquid food industries. Besides the parent company (KHS GmbH) the group includes various subsidiaries outside Germany, with production sites in Ahmedabad (India), Waukesha (USA), Zinacantepec (Mexico), São Paulo (Brazil) and Kunshan (China). It also operates numerous sales and service centers worldwide. KHS manufactures modern filling and packaging systems for the high-capacity range at its headquarters in Dortmund, Germany, and at its factories in Bad Kreuznach, Kleve, Worms and Hamburg. The KHS Group is a wholly owned subsidiary of the SDAX-listed Salzgitter AG corporation. In 2022 the KHS Group and its 5,002 employees achieved a turnover of around €1.291 billion.

KHS GmbH

Juchostr. 20

44143 Dortmund

Telefon: +49 (231) 569-0

Telefax: +49 (231) 569-1541

http://www.khs.com

Presse- und Öffentlichkeitsarbeit

Telefon: +49 (251) 625561-243

E-Mail: deppe@sputnik-agentur.de

![]()