Collaboration between DMG MORI and FOBA

DMG MORI has developed a process chain for its in-house showroom in Bielefeld. The idea behind it is to create real production conditions in order to make the added value of digitalized manufacturing processes tangible for customers. This makes every production step comprehensible – from the raw material to the finished product. At the same time, the green transformation is promoted through increased productivity, reduced energy consumption and careful use of resources.

The process chain starts with the 3D printing of an aluminum robot head and is exemplary for many possible applications in industrial production. The robot head is then provided with a sticker containing order information. This label cannot remain on the component during the subsequent production process, as it would no longer be securely legible after CNC machining with cooling lubricant. A solution therefore had to be found for permanent and reliable identification of the robot head, and this is where DMG MORI called in the laser marking experts from FOBA.

Dr. Rinje Brandis, General Manager Additive Manufacturing and Industry 4.0 ADDITIVE INTELLIGENCE at DMG MORI Academy GmbH, explains why FOBA was chosen: "We were looking for a partner that has extensive expertise in this area and can support us with marking and integration into the digital process chain."

For Christian Söhner, Global Vertical Manager Medical at FOBA, this type of collaboration and the topics that are implemented with the process chain fit in with FOBA’s focus: "Process integration, automation and digitalization are topics that play a central role at FOBA. That’s why we were immediately enthusiastic when we heard about the idea of the process chain. This proximity to industry means we always have an eye on what moves our customers. In this way, we develop pioneering solutions for product marking that are adapted to the needs of the industry and are therefore able to respond flexibly to individual requirements."

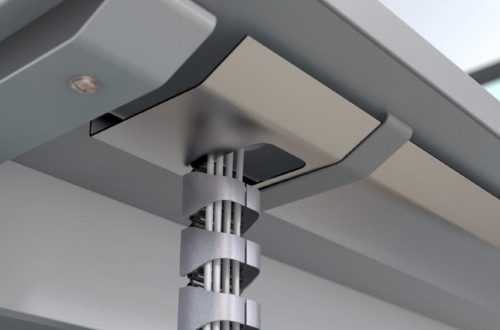

In the FOBA M2000-P laser marking workstation, the robot heads are marked with the company logo, the serial and product number and the customer’s component number. The digital production file can also be read using a DataMatrix code. Further processing steps follow in the process chain, such as milling, wire erosion and a 3D scan.

The process chain – which is permanently on display in the DMG MORI showroom in Bielefeld – was also shown at EMO Hanover, the world’s leading trade fair for production technology, in the DMG MORI City, which covered an area of around 9,000 m².

FOBA Laser Marking + Engraving (brand of ALLTEC Angewandte Laserlicht Technologie GmbH) is one of the leading suppliers of advanced laser marking systems. FOBA develops and manufactures marking lasers for integration as well as laser marking workstations with vision assisted marking workflows. FOBA technology is being applied for the direct part marking of any kind of metals, plastics or other materials in industries like automotive, medical, electronics, plastics or tool, metal and mold making. With its worldwide sales and service branches and its headquarters near Lübeck/Hamburg (Germany) ALLTEC/FOBA is part of the Veralto Corporation.

FOBA Laser Marking + Engraving (ALLTEC Angewandte Laserlicht Technologie GmbH)

An der Trave 27-31

23923 Selmsdorf

Telefon: +49 (38823) 55-0

Telefax: +49 (38823) 55-222

https://www.fobalaser.com

Campaign & Event Manager

Telefon: +49 38823 55-440

E-Mail: kathrin.urban@fobalaser.com

![]()