Keeping pace with the move towards automation

The future of automated milling

With a new robot system, toolcraft is using state-of-the-art technology to set new standards in robot machining. For example, robots can now be used to perform manufacturing steps such as milling, deburring, grinding and polishing components made from a wide range of materials, including metallic workpieces. For this project, toolcraft AG’s robotics team played a key role in the development of a 6-axis robot from Autonox Robotics GmbH, which is even more rigid and therefore more precise.

Offline programming using CAM path planning allows the robot cell to be programmed efficiently and quickly in a similar way to a CNC machine tool and also enables movement patterns and reachability to be simulated. This means that machine operators who only have experience with traditional machine centres also find it easy to switch to using the robot.

The application can be extended by adding almost any number of tools, creating a flexible and efficient manufacturing process, since many different tools can be provided for automated running periods. A nominal reach of two metres combined with a simultaneously rotating machining table also allows larger components to be machined with just one or very few clamping setups. The rotating table has a load-bearing capacity of up to 5,000 kg. “The system can be extended as required. For example, we could add a chip conveyor, extraction unit or climate control system,” says Andreas Bauer, Robotics Business Unit Manager at toolcraft.

An all-rounder for laser metal deposition and milling

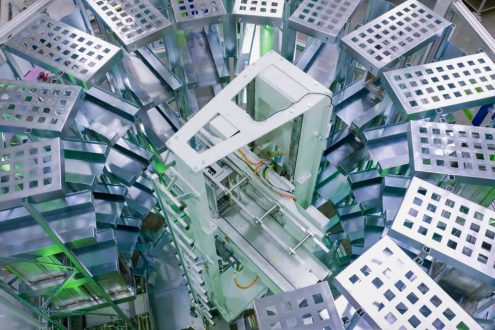

The second recent new development from toolcraft is a hybrid robot application that can be used for both additive and subtractive machining. The laser welding head can machine components using directed energy deposition (LMD/DED). This technique coats and adds new contours to existing components using selective material deposition. Damaged and worn components can also be repaired by depositing material where it is required, with the laser-based and intricate welding process transferring very little heat into the workpiece. Besides saving costs, repairs use fewer materials than making new components and allow for combinations of materials that were not previously possible. The robot from Mabi Robotic has a machining radius of 2.25 metres, making it suitable for both small and large components. In addition to “traditional” laser-powder deposition welding, extreme high-speed laser application (EHLA) deposition can be used to coat rotationally symmetrical components very efficiently, e.g. with a hard or wear-resistant coating. The adaptive motor spindle allows components to be pre-machined, welded and post-machined in a single clamping setup within the same robot system. The switch from welding to milling is also fully automated without the need for any manual intervention. This allows surfaces to be prepared for the welding process, reference surfaces to be produced during the manufacturing process and surface finishes to be machined in further steps. With reachability of around two metres combined with a rotating and swivel unit as the machining table, the robot can be used for flexible, 8-axis manufacturing of complex geometries. Comprehensive Siemens NX offline programming allows movements to be simulated separately from the manufacturing process and to be programmed using extremely precise path planning. “The combination of two manufacturing processes in one robot cell is especially remarkable,” says Christoph Hauck, Chief Technology and Sales Officer at toolcraft. “It’s a true all-rounder that has the potential for many different extensions,” he adds.

The medium-sized family-owned company, located in Georgensgmünd and Spalt, was founded by Bernd Krebs in 1989. toolcraft is a pioneer of forward-looking technologies, such as additive manufacturing and the construction of customised turn-key robotic solutions. As a provider of comprehensive solutions, toolcraft covers the entire process chain, from the initial idea to manufacturing, quality assurance and testing in the areas of CNC machining, additive manufacturing, injection moulding and mould making. Its clients include market leaders in the semiconductors, aerospace, medical technology, optical, special machinery manufacturing, motor sports and automotive industries. Building close working relationships with collaborative partners as well as universities, other institutions of higher education and research centres is an important part of its corporate philosophy.

toolcraft AG

Handelsstraße 1

91166 Georgensgmünd

Telefon: +49 (9172) 6956-0

Telefax: +49 (9172) 6956-560

http://www.toolcraft.de

Marketing

Telefon: +49 (9172) 6956171

E-Mail: juliarodenbuecher@toolcraft.de

![]()