Waste-free automatic tying system ATS flex now available worldwide

This successor to the Autotool ATS3080 sets a new standard in waste-free bundling, offering unparalleled speed, efficiency and process reliability.

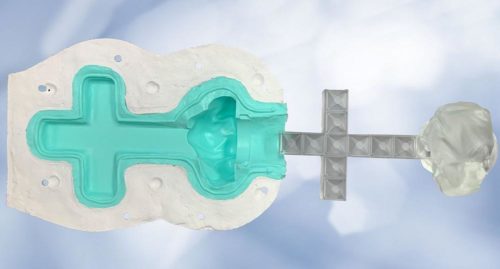

“Unlike conventional cable tie processing, the ATS feeds the strap and closure head separately from reels, using only the exact amount of material required,“ explains Christian Schulze, Product Manager for Automatic Tying Systems (ATS) at HellermannTyton.

“The best way to manage industrial material waste is to avoid creating it in the first place. We are proud to be able to offer our customers the option of eliminating excess strap cut-offs. Using the unique ATS flex saves approximately 100 kg of strap waste compared to using 150,000 conventional cable ties.”

Speed and versatility are also key advantages when using the ATS flex. Thanks to the next generation of electronics, the cycle times per tie are up to 25 percent faster. The tool automatically calibrates and optimises on the first two cycles, an integrated sensor detects proper closure.

Three quick-change jaws (30mm, 50mm, 80mm) are included, with an additional jaw size available to order for bundles up to 100mm in diameter, and specially designed jaws for bundling foot parts commonly used on wire harnesses.

At the request of customers who wish to clearly mark their packaging with a unique security seal, HellermannTyton has extended the black and natural strap colours to include red, green, yellow and blue. Tie heads are available in black, natural, red, green and other colours on request.

The ATS flex is designed for both stationary and flexible use, with options for bench mounting kits or overhead suspension, providing adaptability and maximum operator safety in different working environments. The system can also be integrated into fully automated production lines.

ATS flex benefits at a glance:

- Eliminates waste from cable tie strap cut-offs

- 25% faster cycle times per binding 1.1 – 2.4 secs (depending on Ø)

- Patent-pending automatic jaw calibration

- Closure detection sensor for quality assurance

- 24V power output and interface for production line integration

- Process control and quality documentation

- Combinations of head and strap colours for unique visual marking.

Target markets for the ATS flex include wire harness making for the automotive, railway and white goods, construction and packaging industries, where millions of cable ties are processed every year.

Click here to view a short video introducing waste-free bundling with the ATS flex:

https://www.youtube.com/watch?v=ghQ-2u9-sjk

Onsite demonstration requests available here:

https://www.hellermanntyton.com/atsflex

HellermannTyton is a leading manufacturer and supplier of quality products for fastening, fixing, installing, connecting, insulating, protecting and identifying electrical cables and network connectivity solutions. We also develop cable management parts to industry-specific requirements. We operate 18 production facilities and develop products in 13 countries. More than 6,000 people work at HellermannTyton in 39 countries.

HellermannTyton

Großer Moorweg 45

25436 Tornesch

Telefon: +49 (4122) 701-0

Telefax: +49 (4122) 701-400

http://www.hellermanntyton.de

Communications Manager Europe

Telefon: +49 (4122) 701-5974

E-Mail: James.Hill@HellermannTyton.com

![]()