A Look Behind the Scenes of „upGrade“ CT-GS20Y

Sustainability is an important issue for Ceratizit Austria GmbH, which the company also passes on to its customers with its "upGrade" grades. Ceratizit’s hardmetal product line is characterized by conscientious use of energy, resource efficiency, economical consumption of raw materials and recovery of secondary raw materials in the form of recycled cutting tools made of hardmetal, resulting in a drastic reduction of the CO2 footprint of the products. Like the premium hardmetal grade CTS20D, the new "upGrade" grade CT-GS20Y is a 10% binder submicron hardmetal with a specified tungsten carbide grain size of 0.5 µm to 0.8 µm. This grade is the preferred choice for drilling and milling tools made of solid hardmetal and covers 70% of this field of application. To fulfill the quality requirements, Ceratizit subjected its new hardmetal grade CT-GS20Y, which consists of 99% high-quality secondary raw materials, to extensive machining tests. The test showed that the hardmetal grade CT-GS20Y is in no way inferior to the established premium hardmetal grade CTS20D in terms of achievable workpiece surface quality and resistance to tool breakage. Nevertheless, Ceratizit wanted to prove that secondary raw materials in their product do not influence deformation and creep properties under extreme thermal and mechanical loads.

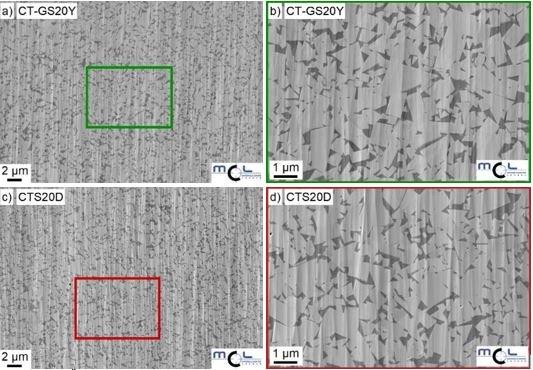

In the course of a joint research project, the research company Materials Center Leoben Forschung GmbH (MCL) investigated the mechanical properties, load and damage behavior of the hardmetal grades CT-GS20Y and CTS20D. High-resolution scanning electron microscopy (SEM) was used at the MCL to assess the microstructure. The SEM images of the sample surface were attained by scanning it with a focused electron beam. This made it possible to analyze the distribution of the tungsten carbides in the cobalt matrix. Figure 1 shows the microstructures of CT-GS20Y and CTS20D. Despite a high proportion of secondary raw materials in the CT-GS20Y grade, both hardmetal grades exhibit the same microstructure. In addition, the shape of the tungsten carbides was examined, which showed no difference between the hardmetal grades.

Furthermore, electron backscatter diffraction studies (EBSD) were carried out to extract crystallographic information: EBSD enables the differentiation of crystallographic phases and, for example, the characterization of grain sizes, orientations and boundaries. Figures 2a) and 2b) show crystal orientation images of the tungsten carbide grains of the "upGrade" grade CT-GS20Y and the premium hardmetal grade CTS20D. The tungsten carbide grain size distribution of both hardmetal grades derived from the EBSD images is shown in Figure 2c). The carbide grain size distributions show values from the nanometer range up to single 2.0 µm grains. Approximately 5,000 carbides were recorded in both EBSD images, the majority of which are present in the specified submicron size between 0.5 µm and 0.8 µm.

During use, for example, as tool materials in metal machining, hardmetals are exposed to high loads and temperatures. Depending on the material being machined, the manufacturing process used and the applied process parameters, temperatures of between 600°C and 1000°C are reached. To understand the materials’ deformation behavior during machining, MCL performed experiments under monotonically increasing and cyclic loads, as well as creep tests under constant load and elevated temperature. A servo-hydraulic testing machine with a vacuum chamber was used to test the hardmetal grades under uniaxial load and at temperatures between room temperature and 900°C, Figure 3a). Changes in length during the test were measured without contact using a high-precision laser extensometer, Figure 3b). The specimen was inductively heated to the desired temperature and the constancy of the temperature over the measuring length was ensured by the use of thermocouples. The specimens have an hourglass geometry to prevent buckling under compression. Figure 3c) shows a glowing sample at 800°C. The stress-strain curves, recorded under monotonically increasing compressive load, show that the stiffness of the two hardmetal grades decreases significantly with the temperature increase from room temperature up to 900°C, see Figure 3d).

Further, both grades exhibit similar deformation behavior at the respective temperatures. Cyclic tests under pure compressive, symmetrical tensile and compressive load as well as creep tests showed the same deformation behavior.

Analyzing the microstructure and deformation behavior, the research company MCL was able to prove that the "upGrade" grade CT-GS20Y has the same properties as the premium hardmetal grade CTS20D under the same loads and at elevated temperatures. This confirmed that the two hardmetal grades are equivalent in terms of these mechanical loads and that high-quality secondary raw materials have no measurable influence on the mechanical and creep properties under extreme mechanical and thermal loads. Ceratizit’s customers therefore benefit from higher price stability and security of supply, as 99% high-quality secondary raw materials are used in the production of CT-GS20Y, which also protects the environment and our climate.

CERATIZIT Deutschland GmbH

Zeppelinstraße 12

87437 Kempten

Telefon: +49 (831) 57010-0

Telefax: +49 (831) 57010-3559

http://cuttingtools.ceratizit.com

PR Manager Cutting Tools

Telefon: +49 (831) 57010-3405

Fax: +49 (831) 57010-3678

E-Mail: norbert.stattler@ceratizit.com

![]()