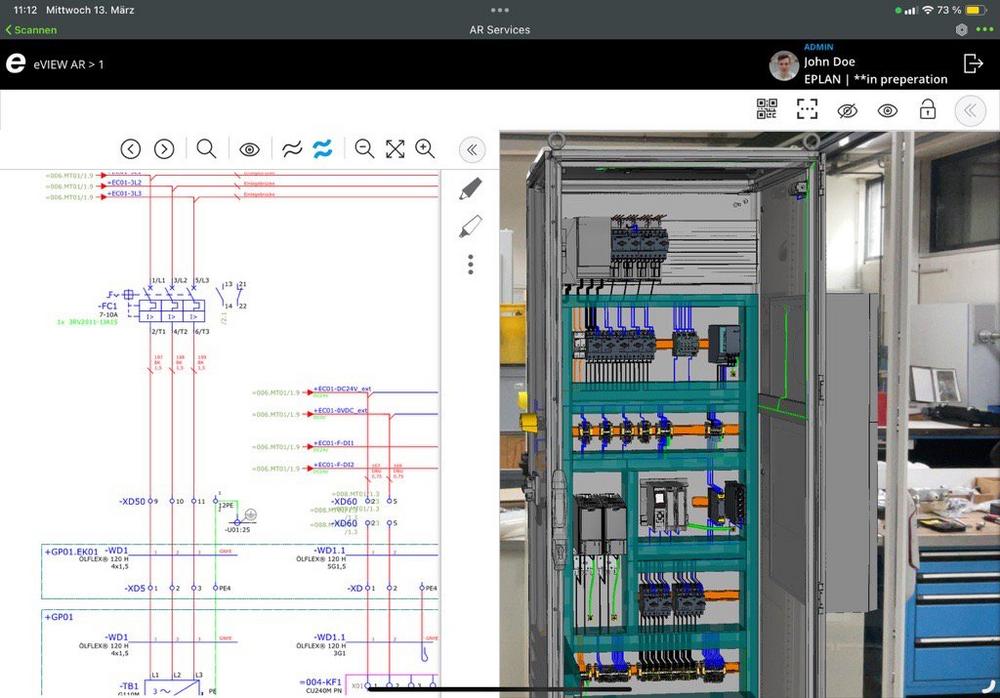

Superimposing the Digital Twin onto the Actual Control Cabinet

Eplan will be presenting a sneak peek into the expanded “eView AR” app in Hanover, Germany. The app has the potential to revolutionise the world of service and maintenance. Specifically, it’s about the electrotechnical documentation of control cabinets, which are made available via augmented reality: not in any project, not at the electrical engineer’s desk, but directly in operations, meaning at the control cabinet itself.

App leads service technicians through the process

With the expanded app, which will be available in May 2024, service technicians can use a tablet or smartphone to overlay the actual control cabinet with its digital twin. In other words, the technician has digital access to every individual component directly at the control cabinet. For example, if a circuit breaker for a motor must be replaced, the service technician is visually guided with AR highlighting and thus knows exactly where the component is positioned within the control cabinet – even if the cabinet door is closed. This allows components to be quickly located, especially in larger control cabinets or a line-up of such. The service technician can then use the digital twin to get all the necessary information, such as the connection point pattern and the schematics page with the motor starter combination. This also eliminates the need to search through what could potentially be very extensive paper documentation. So the app quickly leads the service technician or maintenance employee through the tasks that must be done.

Importing changes back into the project

If, as an example, a contactor must be replaced, the digital twin doesn’t just show the manufacturer’s specifications for the component, it also refers to the electrical engineering documentation. The technician notes the replacement of the part using the redlining or greenlining functions and then the engineering department can simply implement the changes on all the pages of the electrotechnical documentation. If there are cross-references to other schematics pages, these are then also automatically updated in engineering. The best thing is that collaboration in Eplan in bidirectional – from service into engineering and vice-versa.

QR code ensures clear assignment

A QR code generated in Eplan connects the control cabinet’s documentation with the actual control cabinet in operations. The project is stored in the Eplan Cloud and is therefore clearly assigned. The 3D view of the control cabinet layout is superimposed onto the mounting panel and/or the control cabinet itself through the AR functionality. The digital twin from Eplan Pro Panel is overlaid 1:1 onto the components within the control cabinet – simply using a tablet or smartphone. With the AR app, the project documentation is visualised as a schematic in 2D or as a virtual image of the control cabinet in 3D.

Quickly track faults and errors

Split-screen technology allows the schematics and the AR model of the control cabinet to be displayed side by side if desired. This allows faults and errors to quickly be traced back to their source. Another practical advantage is that equipment lists, bills of materials, cable overviews and other evaluations such as topologies can be accessed via cross-references. It ultimately means there is no need to page through the schematics. The complete documentation is available to view at any time and from anywhere in the world through the Eplan Cloud. This simplifies collaboration across departmental boundaries. It also accelerates and simplifies service and maintenance processes. What’s more, the electrotechnical documentation is always accessible and always up to date, which also makes future maintenance and service operations even easier.

The advantages at a glance

- Fast localisation of components for servicing

- Linking the digital twin and actual control cabinet

- Access to the complete and up-to-date project documentation

- Cross-departmental collaboration is made easier

Find out more at: www.eplan.com

Eplan provides design, planning and engineering software and service solutions for all aspects of electrical, automation and mechatronic engineering. The company has developed one of the world’s leading design software solutions for machine and panel builders. Eplan is also the ideal partner to simplify and streamline complex and challenging engineering processes.

Both standardised, as well as customer-specific interfaces to ERP and PLM/PDM systems, ensure data consistency across the entire value chain. Working with Eplan means seamless communication across all engineering disciplines. Regardless of whether the company is large or small: It allows customers to use their expertise more efficiently. Worldwide, Eplan serves and supports over 68,000 customers. Together with its customers and partners, Eplan strives to continue growing and actively advancing integration and automation in engineering. Within the Eplan Partner Network, open interfaces and seamless integrations are implemented together with partners. “Efficient engineering” is Eplan’s core focus.

Eplan was founded in 1984 and is part of the owner-operated Friedhelm Loh Group. The group operates worldwide, with more than 12 production sites and over 95 international subsidiaries. It has more than 12,100 employees and posted revenues of 3 billion euros in fiscal 2023. In 2023, the Friedhelm Loh Group was presented with the “Best Place to Learn” and “Employer of the Future” awards.

For more information, visit www.eplan-software.com and www.friedhelm-loh-group.com.

EPLAN GmbH & Co. KG

An der alten Ziegelei 2

40789 Monheim

Telefon: +49 (2173) 3964-0

Telefax: +49 (2173) 3964-25

http://www.eplan.de

Presse- und Öffentlichkeitsarbeit

Telefon: +49 (2173) 3964-180

Fax: +49 (2173) 3964-163

E-Mail: hagelschuer.b@eplan.de

![]()