The Art of Amperometric O2 Sensing with Zirconia

Over the past 35 years, Angst+Pfister Sensors and Power APSP has pioneered the design and development of oxygen sensing solutions utilizing heated zirconia oxygen-exchange ceramics, which can be categorized into two distinct principles. The first principle leverages a high electrical field between two electrodes to facilitate the separation of charges, resulting in current flow generated within the triple-phase boundaries encompassing the metal electrodes (typically platinum), the heated zirconia oxygen capturing sites, and the oxygen molecules. Conversely, the second principle adopts a static approach, comparing the potential difference between two isolated electrodes exposed to varying partial pressures of oxygen. Notably, the later principle boasts a broader dynamic range compared to the former, as the high electrical field in the former imposes an upper limit on charge removal efficiency, thereby influencing the exposure of oxygen gas.

In the subsequent sections, we will delve into the first principle with current flow in greater detail, elucidating its respective strengths and highlighting applications where it offers significant benefits to processes, thereby enhancing the value proposition for APSP’s customers. Throughout this article, the principle involving current flow will be referred to as the FCX-amperometric principle of O2 sensing. Additionally, all the APSP products associated with these principles bear the prefixes FCX- in their respective names.

FCX-Amperometric Principle of O2 Sensing

The principle of amperometric O2 sensing is relatively straightforward measurement principle, despite the underlying physics being somewhat complex. In this discussion, we’ll simplify the explanation and focus on elucidating the technology’s strengths and its diverse applications tin utilizing heated zirconia for amperometric O2 sensing.

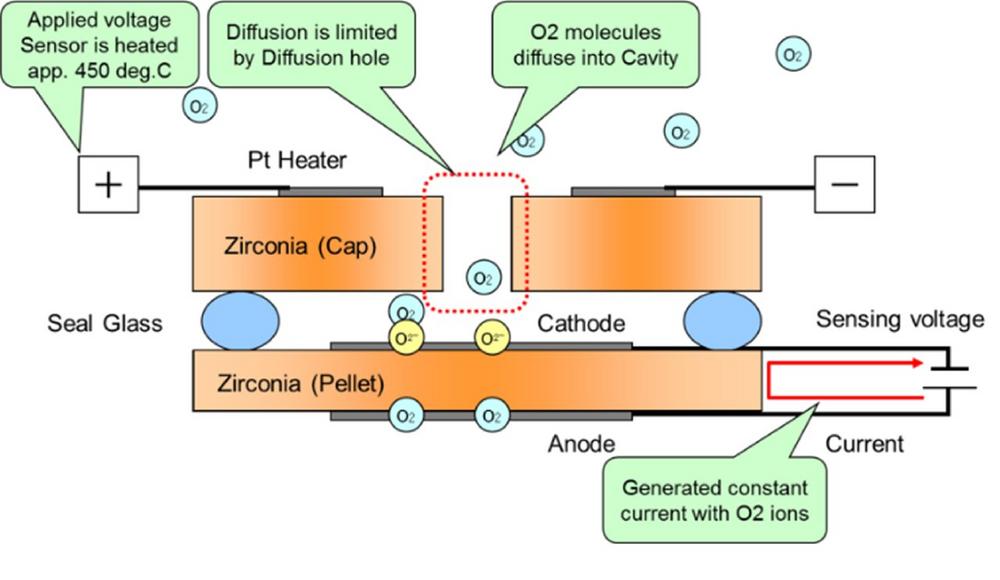

The cross-sectional schematics of the working principle for FCX-amperometric O2 sensor is depicted in Figure 1. When a heated disc of zirconia with two electrodes is immersed in an oxygen-containing gaseous environment, a consistent current flow ensues, which escalates with the applied voltage across the electrodes. This current flow stems from two primary mechanisms: firstly, the temperature of the disc, and secondly, the presence of oxygen. Notably, for oxygen molecules to release their outer electrons at the interface between the heated zirconia and typically platinum electrode, the disc’s temperature must exceed 350°C.

It’s crucial to emphasize that the current flowing in the circuit is unrelated to the surrounding atmospheric oxygen concentration. Additionally, the electrode must be transparent to provide sufficient capture sites for oxygen molecules. An illustrative example of a "transparent" electrode featuring a platinum coherent structure with open surface sites (grain boundaries measuring 2-5 microns in size) is depicted in Figure 2 below.

The current flowing between the electrodes on the heated zirconia disc is modulated by the oxygen concentration through the strategic restriction of gas flow on one side of the disc. This is commonly achieved by affixing a cap with a micron-sized drilled hole (refer to Figure 3), which selectively limits gas flow to one of the electrodes while maintaining consistent partial pressures of various gas elements.

The FCX-amperometric O2 sensor is available with 4 different measurement ranges such as, 0‑1000 ppm, 0-5 Vol% O2, 0‑25 Vol% O2 and 0-95 Vol% O2. The most common application for FCX‑amperometric O2 sensors is, oxygen concentrators, ventilators, incubators, oxygen therapeutic equipment and many more.

Personal consultation, fast reaction times and customised solutions have set Angst+Pfister Sensors and Power apart for close to 30 years.

Our broad and deep range of sensors, power supplies and electronic components ensures you find the right components for your particular field of application. Depending on your requirements, we deliver to our customer standard products, modified standard products or customised solutions. We work exclusively with selected and proven partners that share our uncompromising commitment to reliability, durability, value for money and quality. In addition, the production and distribution of Angst+Pfister Sensors and Power own products complement our broad portfolio.

We do not leave our customers alone during the development phase, but always seek the best solution for your application. Our specialists have deep technical understanding and will accompany through the whole process.

Angst+Pfister Sensors and Power is a daughter company of the Angst+Pfister Group and serves customers across Europe and the globe. We are part of a worldwide network with more than 1 000 employees and 60 000 satisfied customers. With the acquisition of IS-LINE via the Angst+Pfister group, we are able to generate further added value for our clients through expert technical advice and an even broader portfolio in the field of sensors and power electronics. Together we are part of a worldwide network with more than 1,000 employees and 60,000 satisfied customers.

Angst+Pfister Sensors and Power AG

Thurgauerstrasse 66

CH8050 Zürich

Telefon: +41 (44) 87735-00

Telefax: +41 (44) 87735-25

http://sensorsandpower.angst-pfister.com

Marketing Manager

Telefon: +41 (44) 877 35 26

Fax: +41 (44) 8773525

E-Mail: yun.xu@angst-pfister.com

![]()