Efficient separation technology: Flottweg sets new standards at ACHEMA

Industrial centrifuges for efficient separation of biomass in fermentation processes

Downstream processing is a crucial step in industrial biotechnology. Advanced industrial centrifuges can be used to extract these fermentation products from the fermentation broth (downstream processing). In biotechnological processes, the decanter centrifuge is very often a key technology for separating microorganisms from fermentation broths.

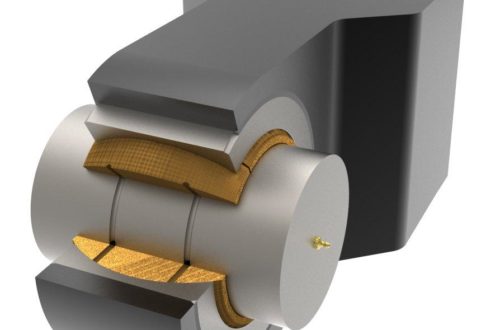

The Flottweg Sedicanter®, which combines the benefits of a decanter and separator, is suitable for fermentation-derived products. Featuring a unique design, the Sedicanter® has been specially developed for soft, flowable solids. The objective is to dewater the biomass efficiently and achieve the maximum yield – even with fluctuating infeed volumes. With a centrifugal field of 5,000 to 10,000g, the Sedicanter® provides high clarification performance and an optimum separation rate.

In a possible second process step, the fermentation broth is clarified by a Flottweg AC series separator in order to separate the remaining solids. Depending on the final product, the focus is either on yielding a highly dewatered solid or the clarified centrate.

Separation solutions for plant extracts

Manufacturers of plant extracts face two major challenges in their production process: The sensitivity and different composition of the products depends on the season (fresh product or dried product). Many manufacturers also process several products on a single process line. Therefore, it is important that the machines used react flexibly to changing framework conditions. Flottweg decanters, separators, and Sedicanters® continuously separate biomass from liquid as efficiently as possible. Decanters are primarily used in preclarification to obtain a high yield of liquid extract. Flottweg separators then clarify the liquid extract for the purest possible end product.

Flottweg is a family business specializing in separation technology that always aims to achieve tangible success for its customers. With an annual turnover of over 298 million euros (2023) and an export rate of over 86%, Flottweg is one of the world’s leading manufacturers of centrifuges, plants and systems. Flottweg always knows what is important to users and applies this knowledge every day to find the optimum solution for its customers. With over 60 years of experience, Flottweg guarantees the highest product quality – Made in Germany. In addition to Flottweg SE, based in Vilsbiburg, Germany, the Flottweg Group has 12 subsidiaries in Europe, Asia, America and Australia. Flottweg also serves its customers in over 100 countries around the world with 50 sales offices.

Flottweg SE

Industriestr. 6-8

84137 Vilsbiburg

Telefon: +49 (8741) 301-0

Telefax: +49 (8741) 301-300

https://www.flottweg.com

PR & Content Managerin

Telefon: +49 (8741) 301 – 1572

E-Mail: delian@flottweg.com

![]()