Excellence in Design: Where Details Make the Difference

Nowadays, conveyors are no longer just devices for transporting materials from point A to point B. They are expected to function like robots, fully automatic and autonomous, seamlessly fitting into our modern world. This is precisely what Avancon conveyors provide.

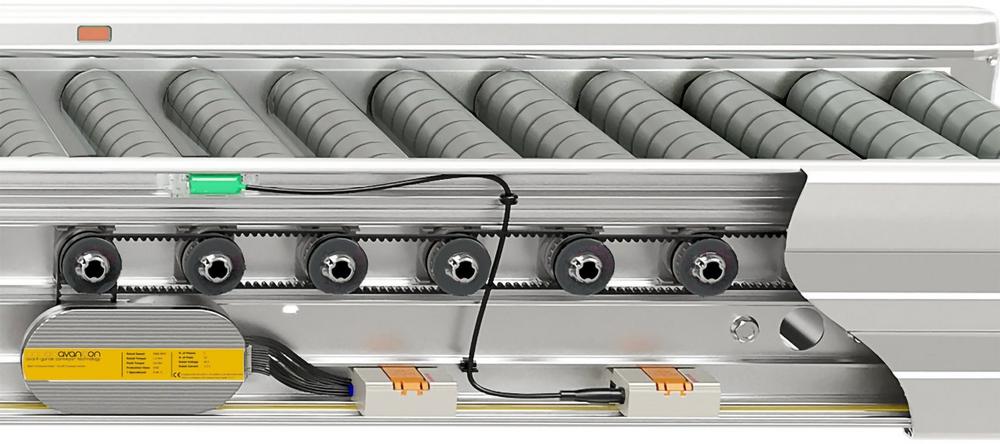

The Avancon ZPC conveyor concept operates in zones (zone-powered conveyor). Designed to prevent material from bumping or exerting pressure during accumulation, these conveyors feature flat brushless DC motors invisibly built into the profile frame. These motors drive their respective zones only when material needs to be conveyed, resulting in significant energy savings. With only one or two 40 W motors needed to convey goods between zones, energy consumption is minimized.

All components, including cables, motors, drive systems, light barriers, and control elements for each zone, as well as the entire control system for automatic and autonomous transport, are housed inside the profile frames, invisible and protected from external factors. Remarkably, all these components can be easily assembled without tools (except for the motors), thanks to corresponding ribs and automatically milled recesses in the profiles.

The light barrier, a crucial component for the system’s smooth operation, is snapped into place securely. It communicates with the control center unit to determine whether a zone is occupied or empty, enabling efficient motor control.

If a zone is occupied, the motor is switched off to save energy; if it’s free, the motor is activated, swiftly moving materials to available zones. Thus, the

entire system can transport goods quickly, reaching speeds of up to 1.5 m/s while consuming only 40 to 80 W of energy per unit.

Additionally, any misalignment of the light barrier can be easily corrected from outside in a matter of seconds, ensuring uninterrupted operation.

The light barrier’s precision demands its fine beam to hit the opposite mirror’s center consistently. Adjustment is easily done externally without opening the outer profile. Two small holes on the outside allow for simple setting or readjustment using a 2 mm PH or PZ screwdriver. Height and horizontal adjustments are made on the right and left sides respectively. Corrections take seconds, offering convenience in both production and maintenance. The clear polycarbonate housing encases the integrated photoelectric sensor, complemented by the smooth aluminum profile.

At Avancon conveyors (whether roller or belt), there are no protruding elements, eliminating pinch points throughout the system. This attention to detail extends to all patented components or functions of Avancon ZPC Conveyors, emphasizing their commitment to efficiency and safety.

It’s inspiring to see companies like Avancon prioritize creativity and meticulousness in their products, enhancing overall efficiency and safety while making conveyor systems more cost-effective

For a more in-depth look, visit: https://www.avancon.com/…

About Avancon: Avancon is a renowned leader in providing innovative conveyor solutions that prioritize simplicity, efficiency, and reliability. With a comprehensive range of conveyor concepts for systems catering to various industries, Avancon aims to reshape the conveyor market and drive optimized productivity while reducing operational costs. Avancon products are available through conveyor producers or integrators.

AVANCON SA

Via Campagna 27

CH6595 Riazzino

Telefon: +41 (91) 22210-10

http://www.avancon.ch/

Telefon: +41 (91) 791-4453

E-Mail: d.specht@avancon.com

![]()