Quality assurance through digital monitoring of the injection molding cell

Digital process monitoring is becoming increasingly important in the plastics processing industry. The use of real-time data acquisition enables production errors and process deviations to be identified immediately and corrected quickly. This leads to a significant reduction in rejects, optimization of manufacturing processes and more efficient use of resources.

Integration of thermal sensors

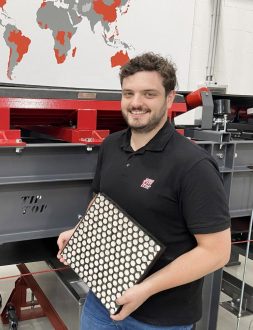

In order to demonstrate what is already technically possible today and to enable further research and development, ADROITEC installed a reference system on a KraussMaffei injection molding machine with comprehensive sensor technology at the SKZ technical center and integrated it into the SKZ’s I4.0 infrastructure. The project partners received support from voestalpine Additive Manufacturing Center GmbH, which provided additively manufactured tool inserts for an existing 4-cavity tool at SKZ. In addition to optimizing the insert temperature control through a near-contour cooling channel design, thermal sensors were integrated into the additively manufactured inserts close to the cavity using a patented process.

Automatic sorting out of bad parts

The Cavity Eye system records and monitors the internal pressures of the cavities and the mold temperature of the inserts in the 4-cavity mold via the temperature sensors installed by voestalpine Additive Manufacturing Center GmbH. The individual cooling circuits of the mold temperature control in the fixed and moving side are also equipped with combination sensors and record the temperature and flow rate separately for each circuit. The system uses defined limit values to decide whether the manufactured parts meet the previously specified customer requirements; bad parts are automatically sorted out by the removal device.

Accurate transfer to database

The system also offers the option of transferring all machine and process data to the database with shot accuracy and visualizing it via a dashboard according to customer-specific requirements. In the event of deviations from the individual limits, an alarm message or notification is sent to the user.

Next training dates planned

Interested parties can experience process monitoring live in the SKZ model factory. The next training dates are already planned for July 2, 2024 and October 29, 2024. Registration at info@adroitec.de

More information about voestalpine High Performance Metals GmbH

More information about the SKZ courses in injection molding

The SKZ is climate protection company and a member of the Zuse Association. This is an association of independent, industry-related research institutions that pursue the goal of improving the performance and competitiveness of industry, especially SMEs, through innovation and networking.

FSKZ e. V.

Friedrich-Bergius-Ring 22

97076 Würzburg

Telefon: +49 931 4104-0

https://www.skz.de

Engineer | Research Injection Molding

Telefon: +49 (931) 4104-304

E-Mail: j.schueder@skz.de

Presse- und Öffentlichkeitsarbeit

Telefon: +49 931 4104-197

E-Mail: p.lehnfeld@skz.de

![]()