New S50ROS cable tie helps vehicle and equipment manufacturers to reduce climate impact

Manufactured from polypropylene (PP), the S50ROS cable tie has a carbon footprint up to 70% lower than equivalent polyamide 6.6 cable ties.

"The S50ROS is a cost-effective choice for reducing CO2 emissions without compromising on performance," says HellermannTyton’s Senior Product Manager Artur Hofer. "This cable tie is part of the ongoing efforts to improve the carbon footprint of our product solutions," he reports. "Many of our customers and partners are not yet aware that polypropylene requires less equivalent energy to produce than many commonly used engineering resins – it is also a highly recyclable material with a growing circular economy. The S50ROS highlights these benefits."

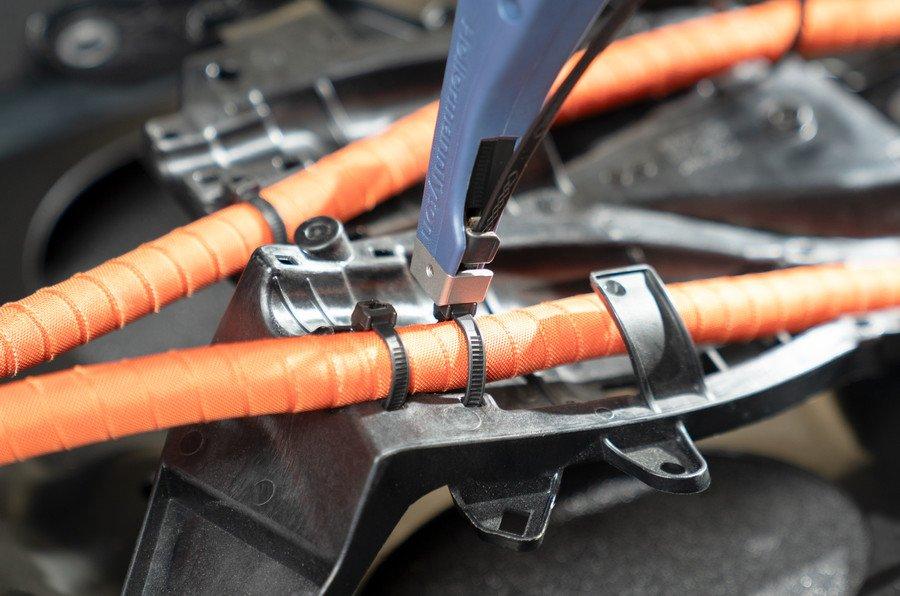

In addition to the climate benefits of switching to polypropylene, the S50ROS is technically suitable for cable management in demanding conditions: It has a tensile strength of 185N and higher chemical resistance than many other common polymers. Measuring 200 mm long by 4.9 mm wide, this cable tie is ideal for securing bundles up to Ø 50.0 mm.

"The challenge was to develop our polypropylene cable tie design to achieve comparable tensile strength with existing standard cable ties made from nylon", reports Artur Hofer. "We also needed to ensure that the tie would maintain its performance under continuous temperature and heat ageing, and that it would also be compatible with our existing two-piece fastening solutions, which combine standard cable ties with mounts for bolts, holes and edges. The S50ROS ticks all of those boxes."

The S50ROS provides a durable and reliable solution to all industries. The automotive industry, for example, benefits from the high tensile strength and chemical resistance. In the electronics industry, the outside serration and anti-slip internal surface reduce the risk of abrasion damage to sensitive insulation. The construction industry benefits from the high resistance to bases and acids of this bundling all-rounder.

The S-Series is manufactured regionally for customers in Europe, helping to keep transport emissions down and further reducing the overall climate impact of our products for our customers.

S50ROS benefits at a glance:

- Contributes to CO2 emissions reduction goals

- Provides comparable performance to nylon ties

- Withstands harsh environments

- Meets high industry standards

- Fully compatible with HellermannTyton cable tie tools.

Find out more about how the S50ROS can support your sustainability goals at

https://www.hellermanntyton.com/s50ros

Samples of S50ROS cable ties are available on request for a no obligation performance evaluation.

For more information on responsible material selection in cable management, visit the HellermannTyton website: https://www.hellermanntyton.com/material-substitution

HellermannTyton is a leading manufacturer and supplier of quality products for fastening, fixing, installing, connecting, insulating, protecting and identifying electrical cables and network connectivity solutions. We also develop cable management parts to industry-specific requirements. We operate 18 production facilities and develop products in 13 countries. More than 7,000 people work at HellermannTyton in 40 countries.

HellermannTyton

Großer Moorweg 45

25436 Tornesch

Telefon: +49 (4122) 701-0

Telefax: +49 (4122) 701-400

http://www.hellermanntyton.de

Communications Manager Europe

Telefon: +49 (4122) 701-5974

E-Mail: James.Hill@HellermannTyton.com

![]()