New Integration of the Calculation of Gears, Shafts, etc. in 3D CAD

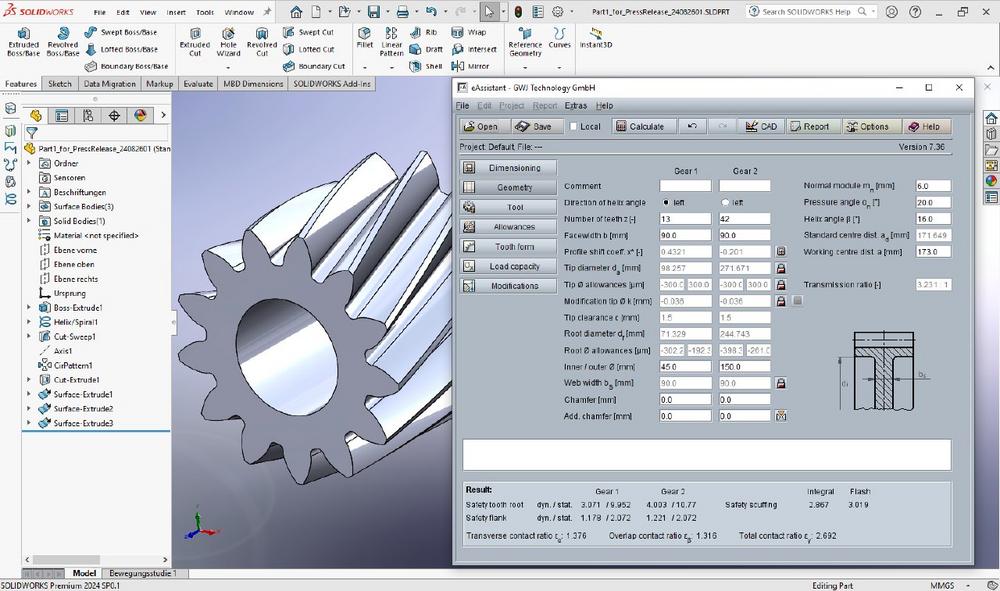

The single calculation modules of the eAssistant can be started directly from the menu integrated in the respective CAD system. The previous method of starting the calculation modules via a browser such as Chrome, Edge or Firefox, which required downloading a start file and clicking on it, is now completely unnecessary. The modules are launched directly without any detours. This increases convenience and speeds up switching between design and calculation.

Using these calculation integrations or CAD plugins, the corresponding 3D models can be automatically generated directly from the calculations performed for cylindrical gears, racks, involute splines, bevel gears or shafts using the native functions of the respective CAD system. The tooth form of involute gears is created based on a mathematical manufacturing simulation, similar to traditional manufacturing using hobbing or gear shaping for a specified tolerance position. This means that the 3D models can be used directly for manufacturing, such as 3D printing, wire eroding, laser cutting, etc.

In addition, the calculation information is stored in the generated models. This allows the original calculation to be accessed directly from the 3D CAD model. The calculation can then be modified and the already created component can be adjusted.

In addition, spur gears or splined shafts/hubs can be cut into existing models.

It is also possible to automatically generate design tables with manufacturing data directly on the drawing. This eliminates errors in the transmission of basic gear and test data, and makes work faster and easier. These tables can also be customized using templates. Multiple templates for the same gear type are possible. The appropriate template can then be selected directly from a list box before it is placed on the drawing.

Visit www.gwj.de for more information or contact GWJ at +49 (0) 5311293990 or send an email to info@gwj.de.

Focusing on mechanical engineering, GWJ Technology stands for high-quality products and professional software development for mechanical engineering to support engineers and designers in their daily work.

The GWJ product range of innovative calculation software is wide – from standard software for classical machine elements with 3D CAD integration modules to the determination of whole systems up to a complex special software for 5-axis milling of gears.

There are common features that all GWJ solutions share – intuitive design, sleek interface, easy to use and suitable applications for all users from beginner to very advanced. GWJ is constantly working on software enhancements and adding new features to the system in order to keep the applications up-to-date.

Professional competence, state-of-the-art technology, a demand for high quality and excellent customer services are the key factors in GWJ´s business philosophy to give the customers the best possible service and advice to obtain new competitive advantages.

GWJ Technology GmbH

Celler Straße 67 – 69

38114 Braunschweig

Telefon: +49 (531) 129399-0

Telefax: +49 (531) 129399-29

http://www.gwj.de

Technische Dokumentation

Telefon: +49 531 1293990

Fax: +49 531 12939929

E-Mail: s.sack@gwj.de

Geschäftsführer

Telefon: +49 (531) 1293990

Fax: +49 (531) 12939929

E-Mail: g.weser@gwj.de

![]()