Miniaturized Galaxie® actuator: High-end performance for precision robotics

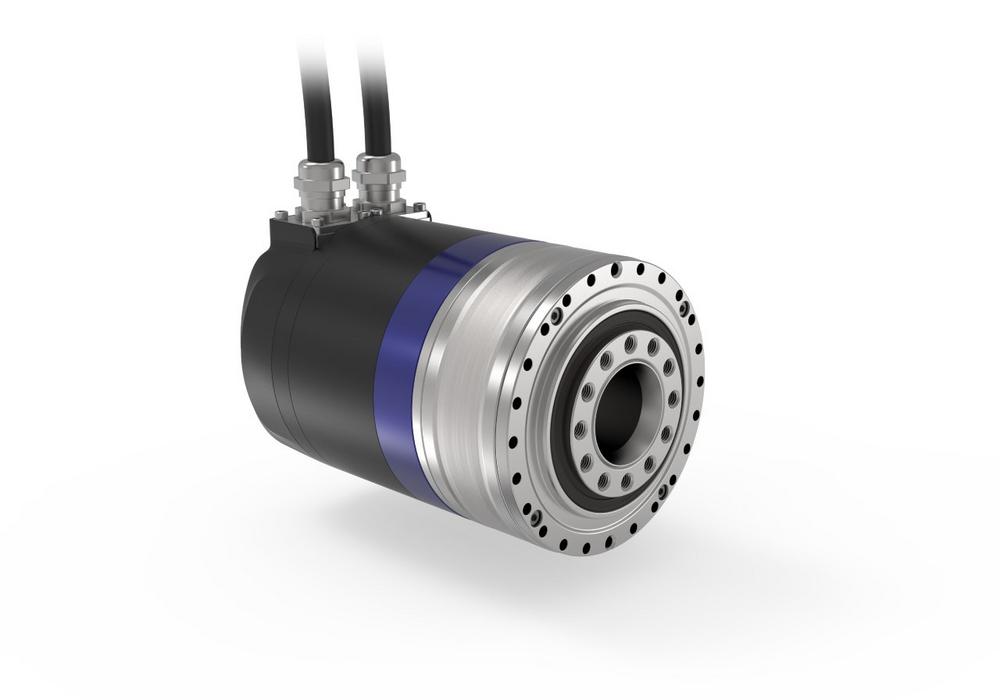

A frameless motor from the cyber® kit line small, combined with a miniaturized Galaxie® gearbox with a hollow shaft up to 35 mm in size – the new miniaturized Galaxie® actuator unites innovative mechatronic system components in a space-saving and integration-friendly design.

More precision and productivity

With its extremely high torsional rigidity, the miniaturized Galaxie® actuator – probably the most compact of its kind available today – enables high acceleration rates with less vibration and hence maximum productivity in the application. What’s more, it guarantees best-in-class precision – on the one hand, thanks to its true zero backlash and special dampening properties and on the other, through an additional encoder on the output side, which further improves control quality and precision too. At the same time, the high rigidity and power density of this modularly configurable actuator open up possibilities for downsizing the robot’s drive train, as a way to save space and weight or upgrade the application’s performance. Compared to other installation-compatible drive solutions currently on offer in the market, the large hollow shaft makes it easy to feed through cables or media supply lines. That significantly reduces the complexity of the motor-controller connection and prevents cable breakage during operation – for increased machine availability.

Safety integrated as standard

With its high torsional rigidity and exceptionally high emergency stop torque, the miniaturized Galaxie® actuator automatically provides crucial safety reserves. The integrated dual encoder system adds to this effect, creating system control redundancy, and is an important safety feature for axes, especially in medical robotics.

Miniaturized Galaxie® gearbox combinable with standard industrial motors too

Alongside the actuator solution on show at the upcoming exhibition, the miniaturized Galaxie® gearbox can also be used with standard industrial motors. Adapter plates and clamps are employed to connect them together so that, in theory, a perfect connection can be achieved for any motor. The miniaturized Galaxie® integrates quickly and easily into existing axes as a result. This solution is ideal wherever the overall length of the drive solution is not a key factor.

The new, miniaturized Galaxie® actuator – just perfect for surgical and high-precision robotics!

WITTENSTEIN – one with the future

With around 2800 employees worldwide and sales of €498 million in 2023/24, WITTENSTEIN SE enjoys an impeccable reputation for innovation, precision and excellence in the field of cybertronic motion – not just in Germany but internationally. The group possesses exceptional expertise for the mastery and further development of all technologies relevant to mechatronic drives and comprises six innovative Strategic Business Divisions. We develop, produce and sell products such as high-precision servo drives and linear systems, servo systems and motors as well as cybertronic drive systems for many areas of application including machine and plant construction, aerospace or oil and gas exploration. Nanotechnology and software components round off the portfolio. With 25 sites in more than 45 countries, the WITTENSTEIN group (www.wittenstein.de) is represented in all major technology and sales markets.

WITTENSTEIN SE

Walter-Wittenstein-Straße 1

97999 Igersheim

Telefon: +49 (7931) 493-0

Telefax: +49 (7931) 493-200

http://www.wittenstein.de

Fachpresse und stellv. Pressesprecherin

Telefon: +49 (7931) 493-10399

Fax: +49 (7931) 493-10301

E-Mail: sabine.maier@wittenstein.de

![]()