Toray Creates Stretchable Film with High Dielectric Constant and Resilience that Helps Cut Actuator and Sensor Weight and Energy Consumption

Applications should include dielectric components in dielectric elastomer actuators (DEAs) for robots, sensors for reducing weight and saving energy, flexible sensors suitable for curved 3D curved surfaces, and energy harvesters. Toray will set up a sample distribution system for users and strive to swiftly commercialize this breakthrough.

Recent years have seen attention focus on soft robots to interact with people in such fields as healthcare, eldercare, and food production. Conventional robots require many sensors and complex controls. In contrast, “soft” robots comprising compliant materials instead of rigid links and which can operate safely and autonomously are attracting considerable interest, as are dielectric elastomer actuators as power sources for these devices.

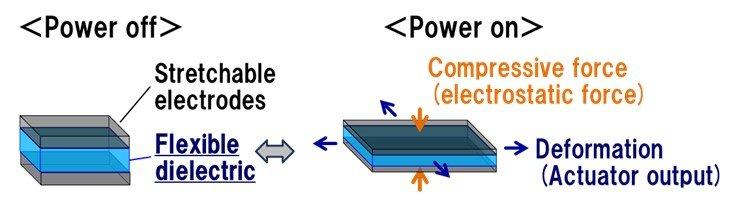

A dielectric elastomer actuator comprises an elastic dielectric film with stretchable electrodes on both sides. Applying a voltage between the electrodes generates a compressive force proportional to the dielectric constant of the film, deforming the actuator and producing an output (see diagram).

These films currently employ such elastomers as silicone and acrylic. Materials with higher dielectric constants are necessary, however, to deliver the high outputs vital for practical applications. High resilience is vital for fast responses. Existing materials and methods present trade-offs between these characteristics, which necessitated the development of new materials.

The REACTIS line has diverse applications. Toray enhanced its technology based on that range to attain a relative dielectric constant of 12, more than double the level of conventional elastomers, while maintaining a 100% recovery rate. The company has confirmed that a dielectric elastomer actuator employing this new film delivers more than four times greater output than conventional actuators using silicone film.

Another benefit is a high dielectric constant without employing materials that could harm the environment, such as halogens and inorganic particles.

Applying this new film to dielectric elastomer actuators could enhance the responsiveness of soft robots in applications that improve the quality of life in the healthcare, medicine, and industrial fields. Using the film as a dielectric material in capacitive sensors could lead to flexible sensors that can measure on 3D curved surfaces and accommodate large deformations.

Toray will keep leveraging its core technologies of synthetic organic and polymer chemistry, biotechnology, and nanotechnology to pursue R&D into groundbreaking materials that can transform the world in keeping with its commitment to delivering new value and contributing to social progress.

Glossary

A dielectric elastomer actuator (DEA) converts electrical energy into kinetic energy by using electrostatic force to attract positive and negative charges to each other.

Toray is a leading technology and advanced materials innovator. We have contributed to social progress since our foundation in 1926 by creating new value. We help the world to overcome new challenges by supplying fibers and textiles, resins and films, carbon fiber composite materials, and other high value-added products. Our approximately 310 subsidiaries and affiliates worldwide employ almost 49,000 people.

For more information, please visit our website at www.toray.com

Toray International Europe GmbH

Hugenottenallee 175

63263 Neu-Isenburg

Telefon: +49 (6102) 79990

Telefax: +49 (6102) 7999291

http://www.toray.de

![]()