Thermography: Effective defect detection in plastic products

Thermography, which involves the use of thermal imaging cameras, has established itself as an extremely effective inspection method for detecting defects in plastics. As an imaging method, it is particularly suitable for the rapid inspection of products of different sizes and is characterized by its non-contact nature. It is particularly suitable for homogeneous, large-area and thin-walled products such as packaging, containers, plates and tubes. It not only detects metallic foreign materials, but also non-metallic particles such as glass, cardboard, wood and stone, as well as non-homogeneous plastics.

Real-time detection of defects

A significant advantage of thermography is its speed and ability to efficiently inspect a wide range of products. This imaging technique provides a rapid inspection of homogeneous, large-area and thin-walled products, making it ideal for various plastic products. Through real-time detection of defects such as foreign material and air inclusions, thermography enables precise quality control without affecting the production process.

Customized solutions

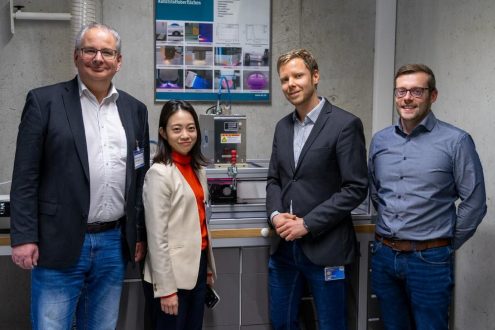

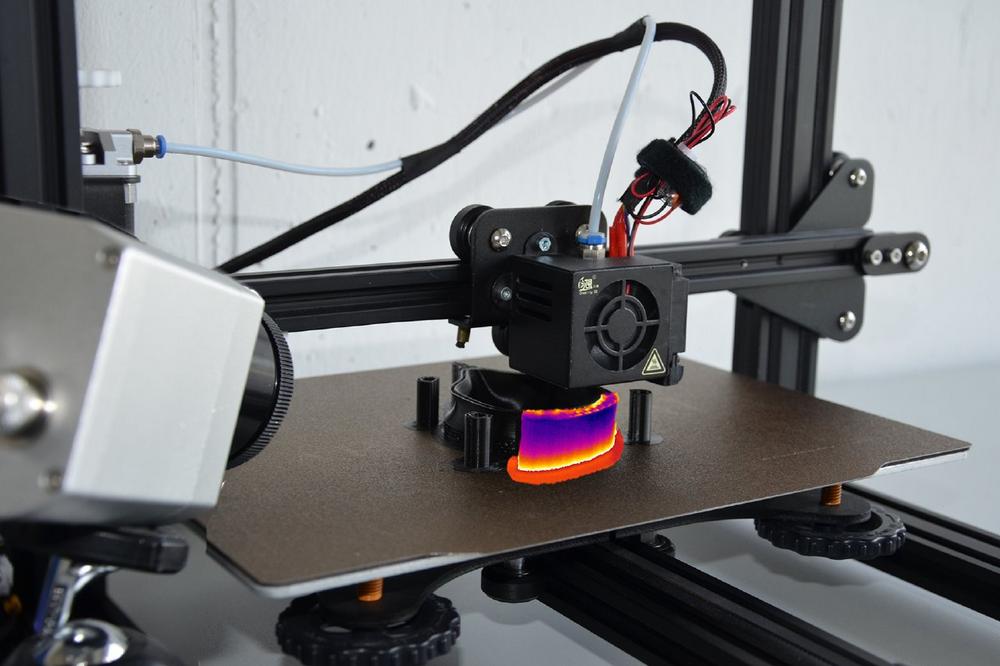

In order to make optimal use of thermal imaging for the specific requirements of end users, SKZ develops customized solutions, for example for use in additive manufacturing. SKZ acts as an independent and neutral partner, not only selecting suitable hardware components but also contributing its extensive expertise in the field of plastics technology and processing.

“For plastics processing companies, thermography often offers the ideal combination of user-friendliness, inspection speed and universality,” says Pierre Pfeffer, Senior Scientist in Non-destructive Testing at SKZ. Interested companies can contact SKZ for an initial consultation.

Further information on non-destructive testing

The SKZ is climate protection company and a member of the Zuse Association. This is an association of independent, industry-related research institutions that pursue the goal of improving the performance and competitiveness of industry, especially SMEs, through innovation and networking.

FSKZ e. V.

Friedrich-Bergius-Ring 22

97076 Würzburg

Telefon: +49 931 4104-0

https://www.skz.de

Senior Scientist | Non-destructive testing

Telefon: +49 (931) 4104-424

E-Mail: d.hoffmann@skz.de

Presse- und Öffentlichkeitsarbeit

Telefon: +49 931 4104-197

E-Mail: p.lehnfeld@skz.de

![]()